Method for forming circuit board without location holes

A molding method and circuit board technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve problems such as uneven board edge, too small diameter of through hole, and influence on circuit board splicing, so as to reduce production time, Optimize the production process, facilitate positioning and test the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

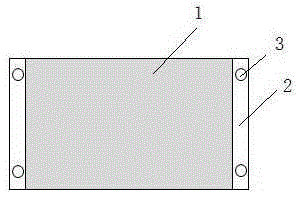

[0028] Such as Figure 3 to Figure 8 As shown, a circuit board molding method without positioning holes includes a circuit board 1 to be processed that is provided with two process sides 2, such as image 3 As shown; the two process sides 2 of the circuit board to be processed are arranged on any two sides of the circuit board to be processed. Wherein each process edge 2 is provided with two positioning holes 3, and the circuit board to be processed is positioned through the positioning holes. Specific steps are as follows:

[0029] S1. Put multiple circuit boards to be processed to the outside in sequence, and then overlap and fix them on the backing plate of the forming machine table; then put the circuit board 1 to be processed into the gong board equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com