Firework cylinder material and preparation method thereof

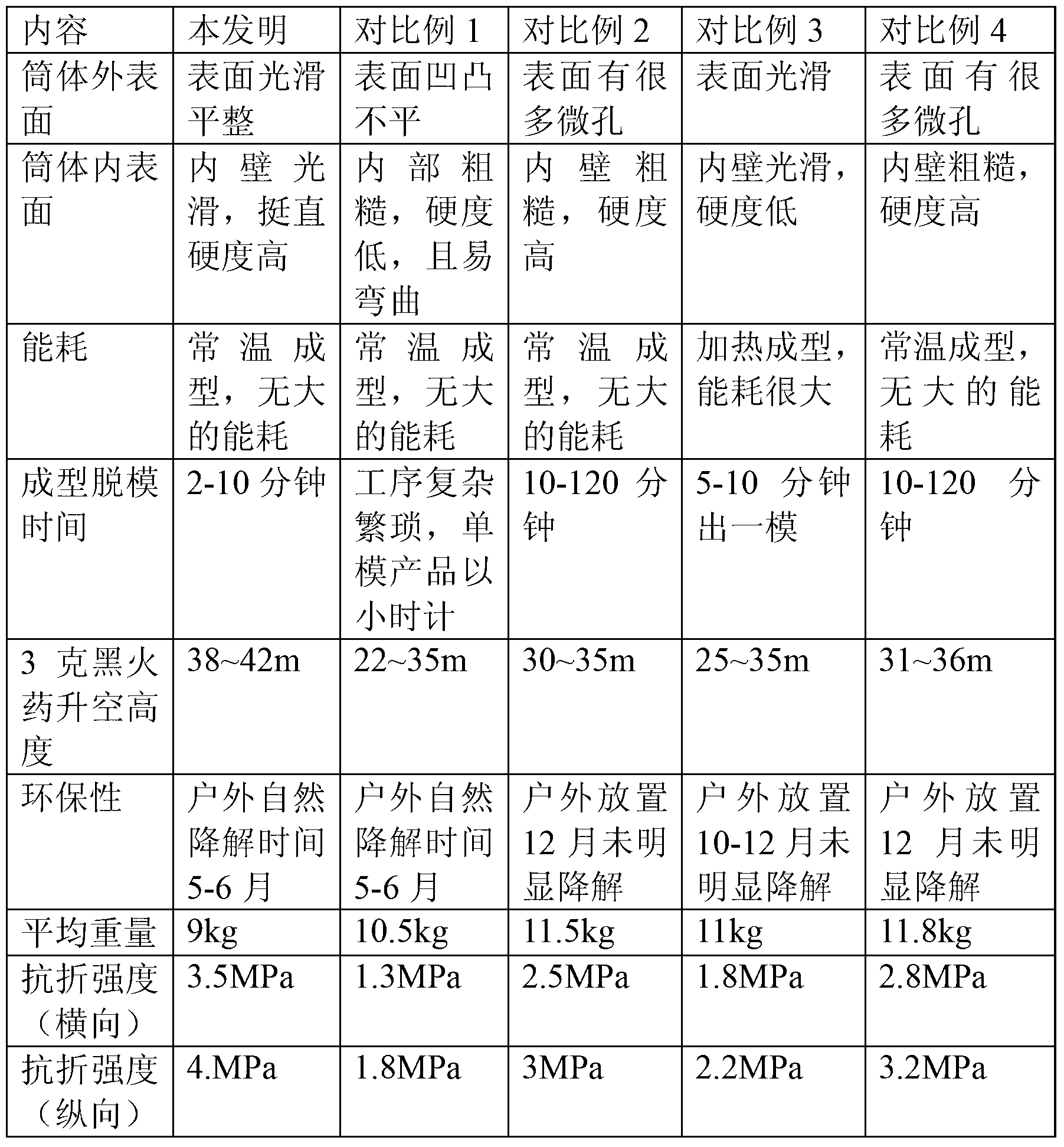

A technology for a body material and a firework tube, which is applied in the field of firework tube body material and its preparation, can solve the problems of difficulty in ensuring product stability, difficulty in improving plant fibers, and inability to satisfy firework shells, etc., and achieves a simple molding method, short molding time, Good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A firework cylinder material, made of the following components in mass percentage:

[0041] Plant fiber 20-55%;

[0042] Reinforcing fiber 0~15%;

[0043] Fiber treatment agent 1~5%;

[0044] Air-hardening materials 25-39%;

[0045] Catalyst 0.1~2%;

[0046] Filler 5~25%;

[0047] Lubricant 0% ~ 2%;

[0048] Coagulant 0% to 2%;

[0049] Toughening agent 5% ~ 15%;

[0050] Foaming agent 0% ~ 5%;

[0051] The stabilizer is 2% to 15% of the total mass of the above formula.

[0052] The preparation method of the above-mentioned fireworks barrel material comprises the following steps:

[0053] 1) Prepare the air-hardening gel by mixing the air-hardening material according to the water-cement ratio of 1:2 to 2:1;

[0054] 2) Formulate the toughening agent into a colloid;

[0055] 3) Spray the fiber treatment agent solution to treat the plant fibers and reinforcing fibers, and stir evenly;

[0056] 4) Add treated plant fibers and reinforcing fibers to the air-harde...

Embodiment 2

[0061]Proportion the raw materials according to the mass fraction: 40 parts of waste paper pulp fiber (excluding water), 5 parts of polypropylene fiber, 5 parts of quicklime, 30 parts of lightly burned powder (including the weight of the blender), 10 parts of perlite, and 5 parts of modified starch , 2 parts of fiber treatment agent, 0.5 part of catalyst, 0.5 part of lubricant, 1 part of coagulating agent, 1 part of foaming agent, and the added mass of stabilizer is 5% of the total mass of the above components.

[0062] Manufactured according to the preparation method of Example 1, the finished product is obtained through preparation into colloid, mixing, injection molding, molding and curing.

Embodiment 3

[0064] Proportion the raw materials according to the mass fraction, 55 parts of waste paper pulp fiber (excluding water), 5 parts of glass fiber, 30 parts of lightly burned powder (including the weight of blending agent), 5 parts of animal glue, 1 part of fiber treatment agent, and 1 part of catalyst , 1 part of lubricant, 1.5 parts of coagulating agent, 0.5 part of foaming agent, and the added mass of stabilizer is 10% of the total mass of the above components.

[0065] Manufactured according to the preparation method of Example 1, the finished product is obtained through preparation into colloid, mixing, injection molding, molding and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com