Plastic package motor with anti-loose end cover

A plastic-encapsulated motor and anti-loosening technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of scrapping of plastic-encapsulated motors, difficulty in disassembly, and increase in production costs, avoiding end caps from falling off, improving firmness and reliability. Reliability and the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

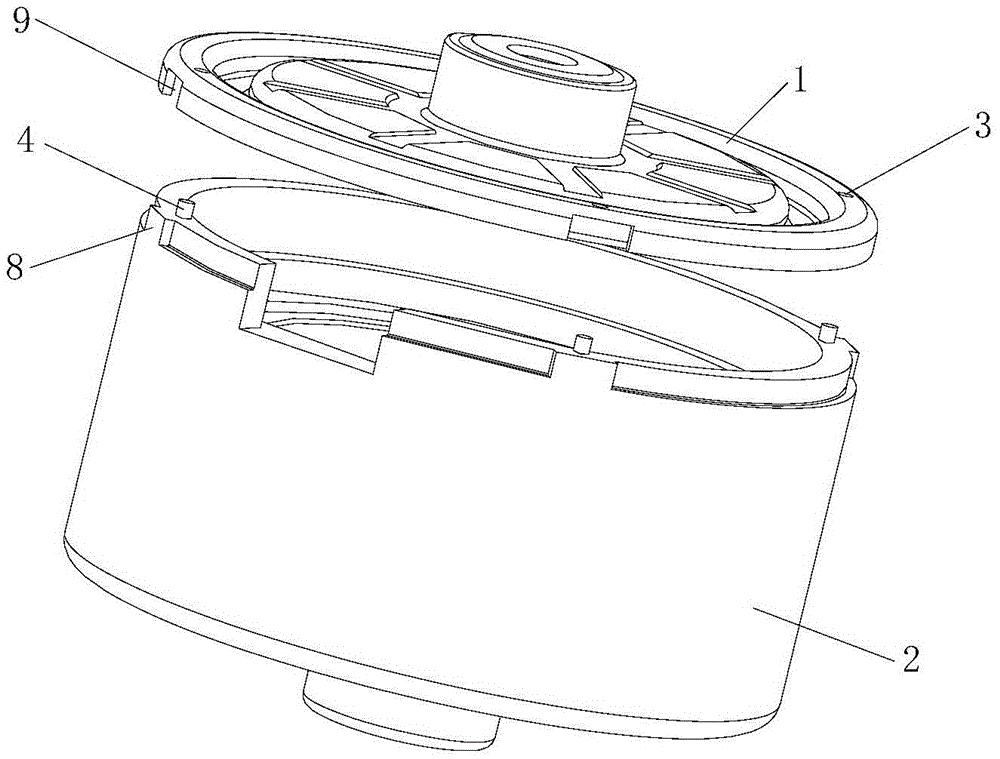

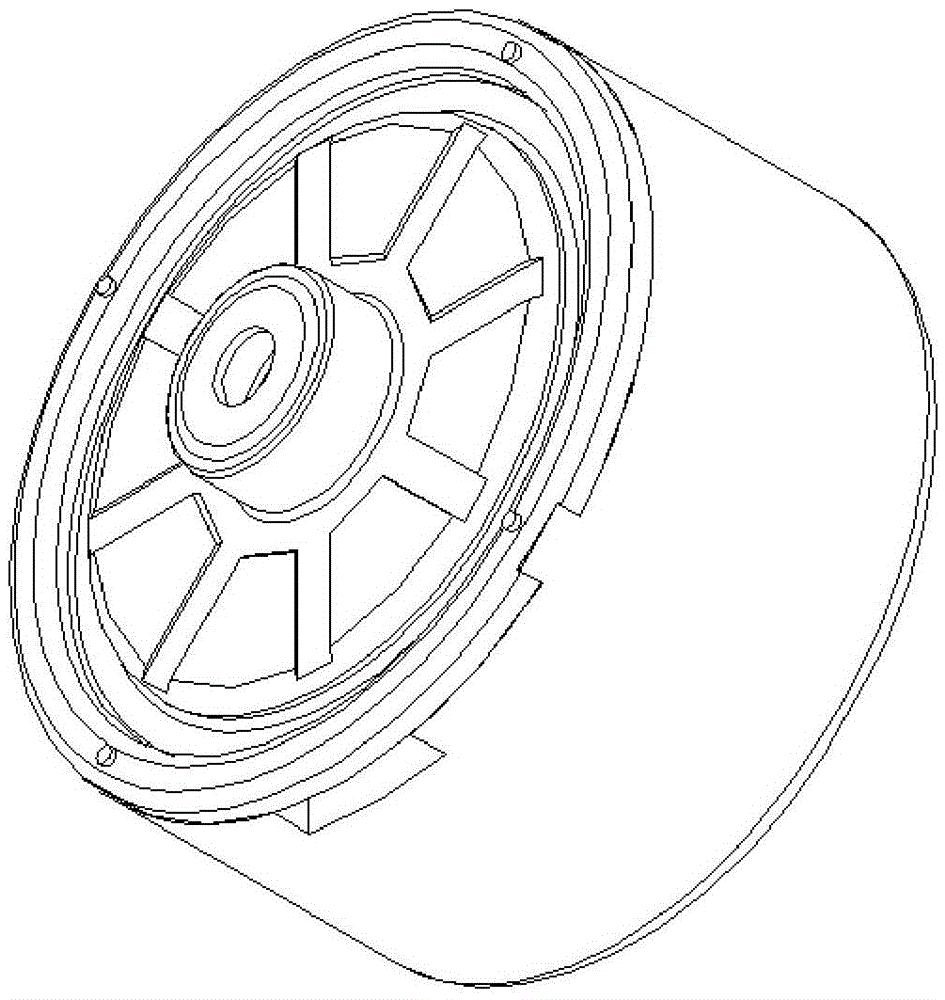

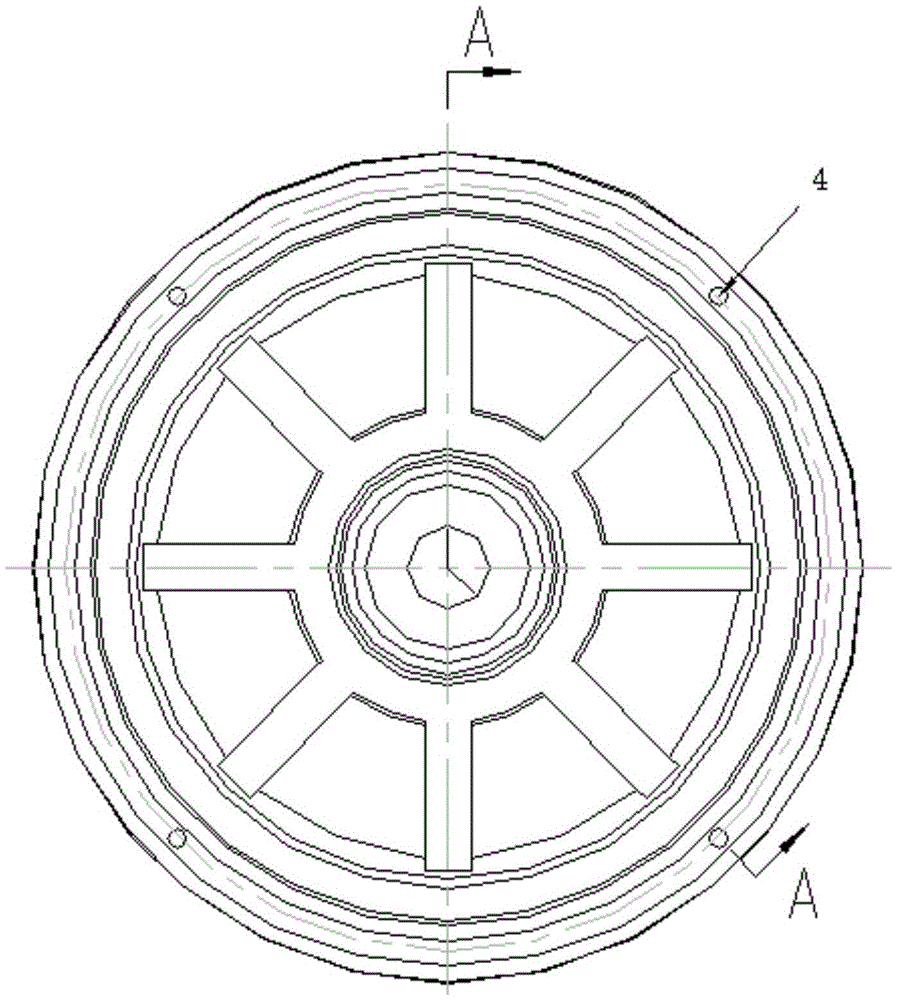

[0039] The invention provides a plastic-sealed motor with an end cap that is anti-loosening, including a plastic-sealed stator, a plastic-sealed motor end cover 1 and connecting fasteners; the plastic-sealed stator includes a plastic-sealed casing 2 and motor components installed in the plastic-sealed casing 2; the plastic-sealed The motor end cover 1 is provided with a fixing hole 3 , and the connecting fastener passes through the fixing hole 3 to fix the plastic-encapsulated motor end cover 1 on the end of the plastic-encapsulated casing 2 . By using connecting fasteners to connect the plastic-enclosed stator and the plastic-enclosed motor end cover 1 together, the firmness and reliability of the assembly between the plastic-enclosed stator and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com