Tube fin brazing process and internal tube heating soldering machine for

A brazing process and brazing machine technology, applied in electric heating devices, manufacturing tools, metal processing and other directions, can solve the problems of difficult temperature control, poor brazing effect, etc., and achieve long service life, reasonable structure, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

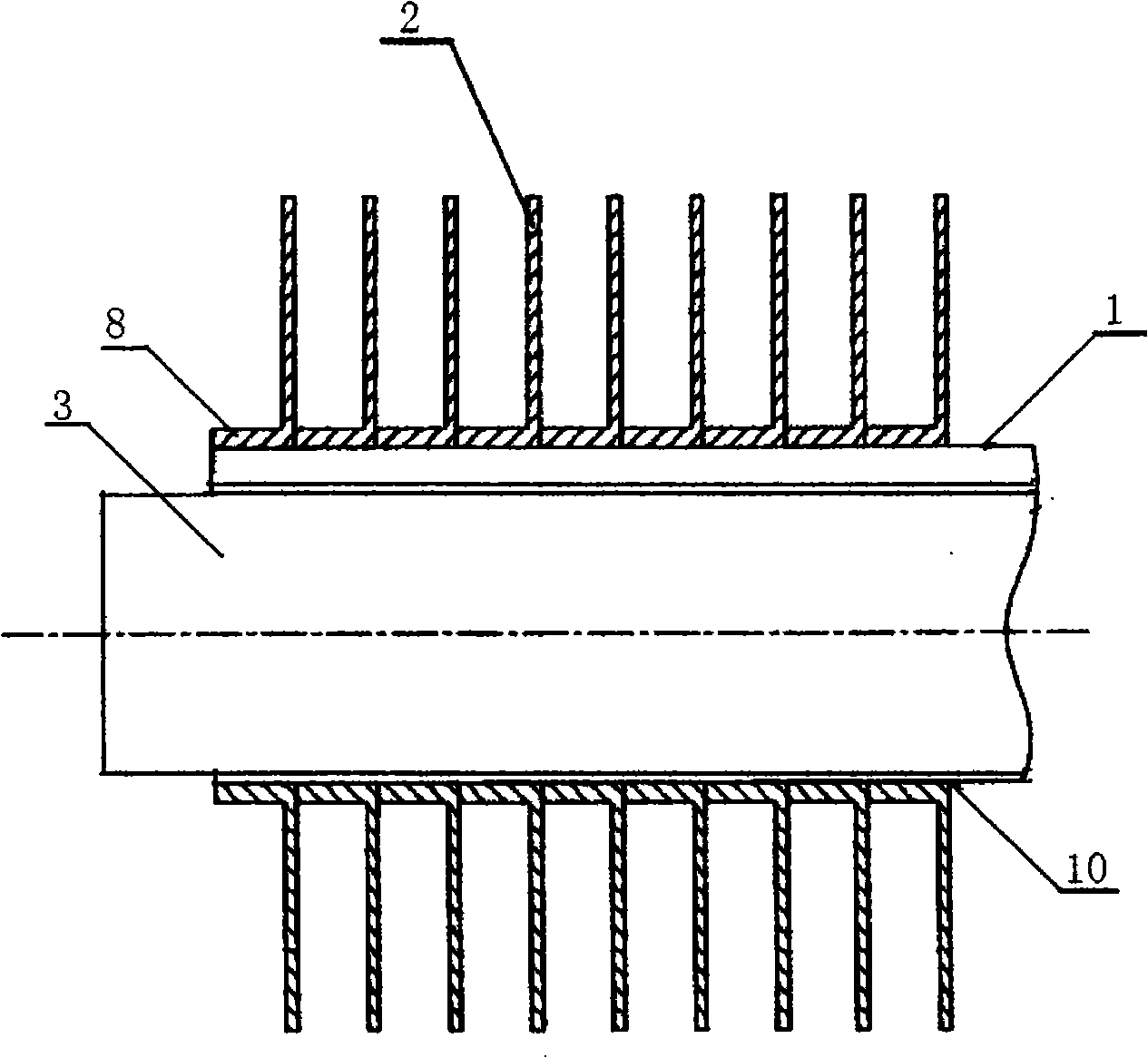

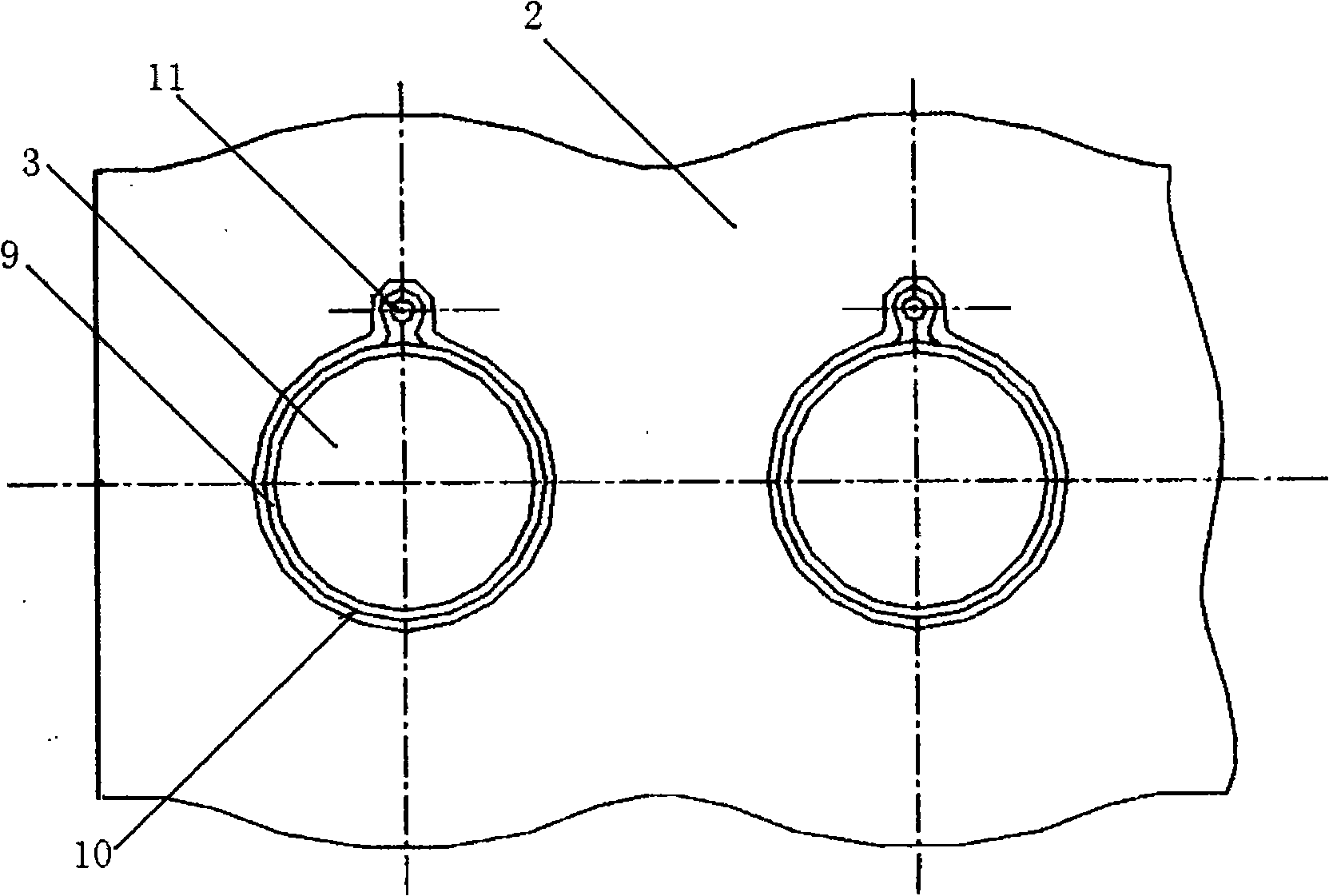

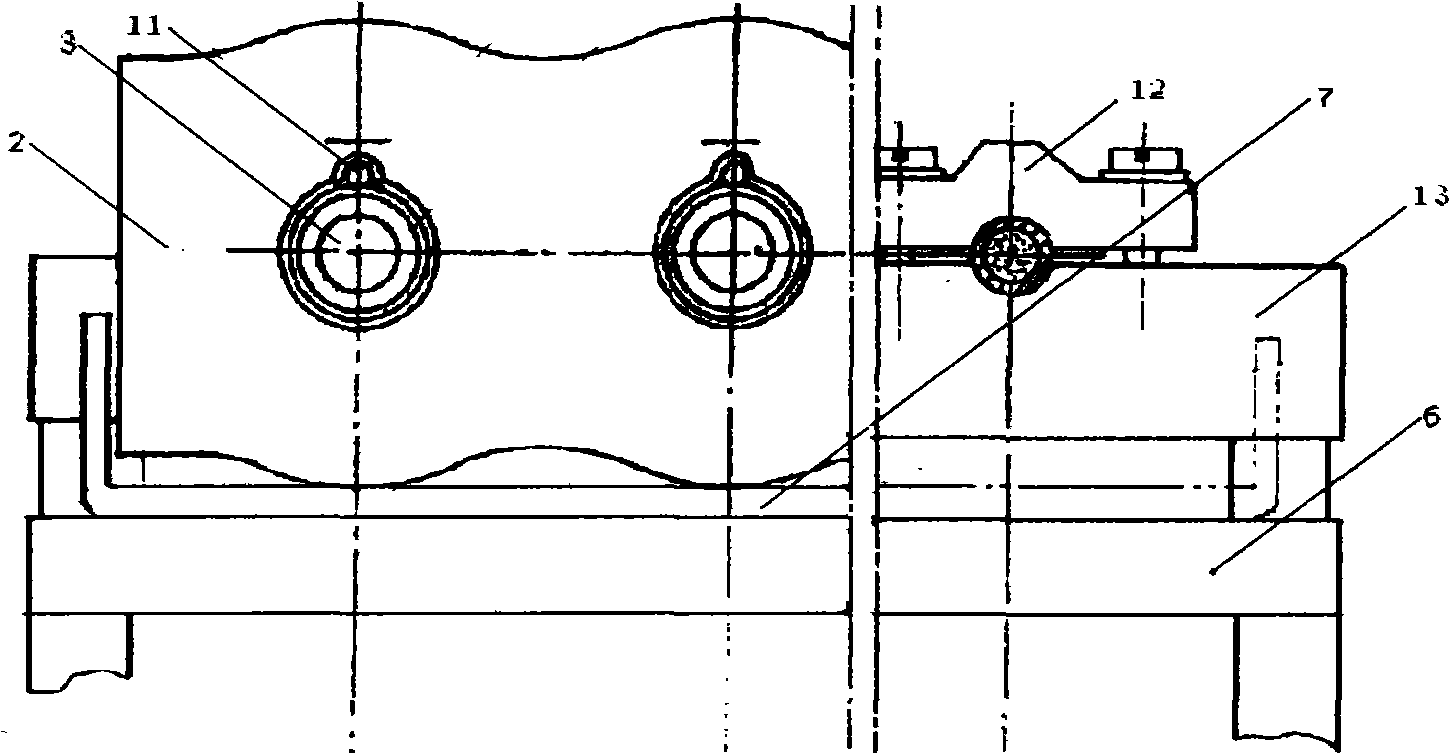

[0015] refer to Figure 1 ~ Figure 2 . The finned tube heat exchanger is composed of multiple pipes 1 and several pieces of fins 2 . The fins 2 are arranged parallel to each other, and are connected through at least two vertical ducts 1 . Each fin 2 is punched with a fin turning edge hole for assembling the conduit 1 on the same plane. And the top of the flanging hole is also punched with a notch 11 for placing solder. A single electric heating tube 3 passes through the catheter 1-shaped lumen. Before brazing, the pipe 1 workpiece equipped with fins 2 must be carefully processed and strictly cleaned to remove oil stains and excessively thick oxide films to ensure the assembly clearance of the fins' folded edge 8 interface. The gap is generally required to be between 0.01 and 0.1 mm. Fill the notch 11 of the joint gap with filling brazing solder with a melting point lower than that of the weldment, and place the finned tubular conduit weldment with the solder 9 assembled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com