Preparation method of Mx' phase VO2 nanometer material with metallic characters under normal pressure

A technology of metal properties and nanomaterials, applied in vanadium oxide and other directions, to achieve the effects of good stability, simple experimental method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

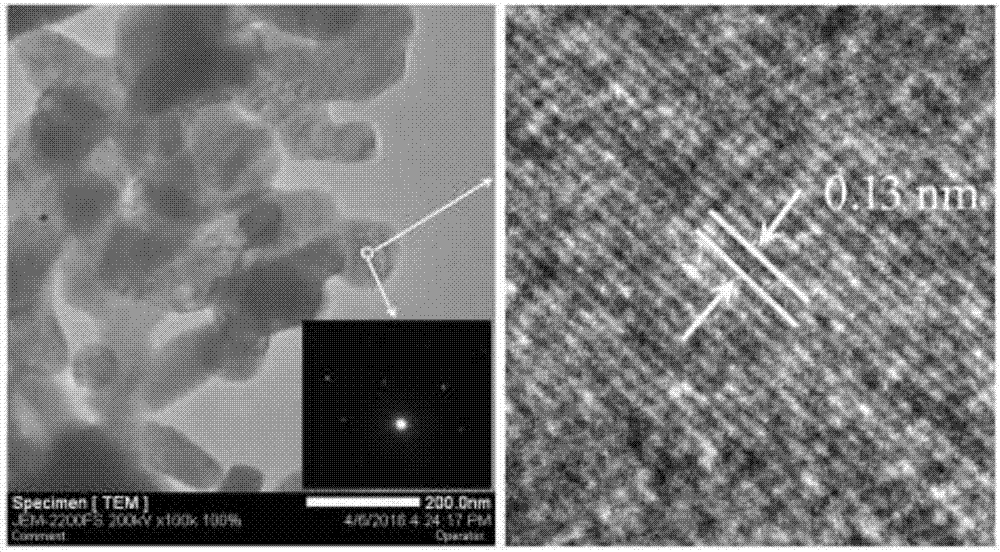

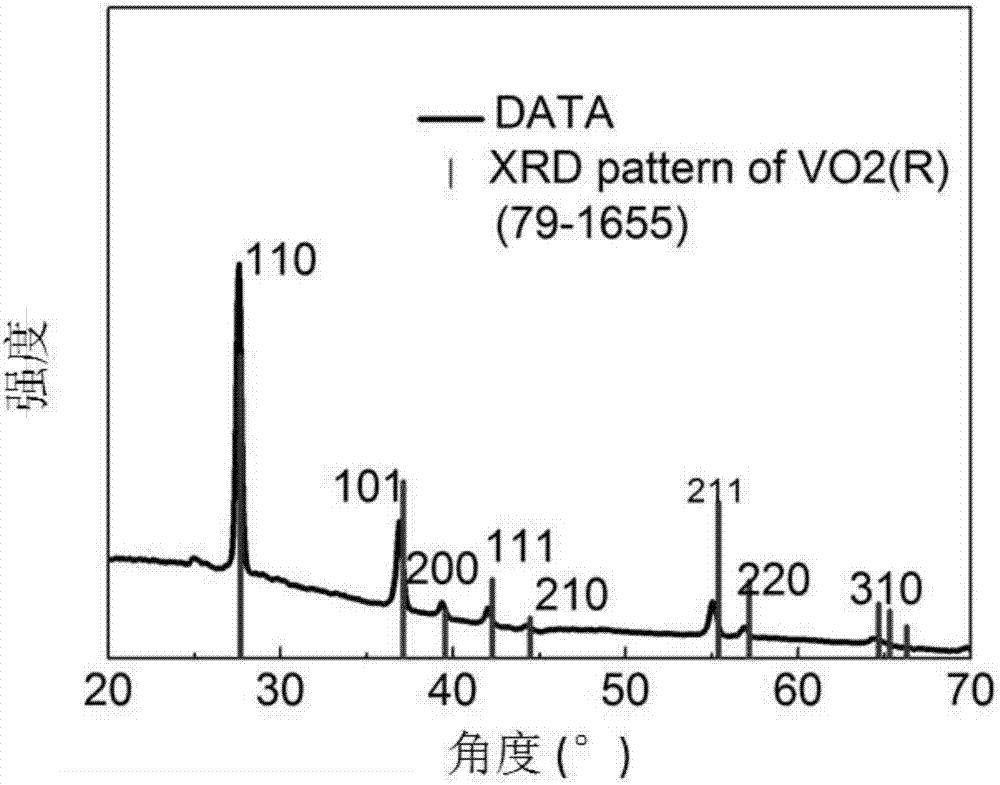

[0021] VO 2 (R) The preparation process of nanoparticles is as follows: 0.2275g V 2 o 5 , 0.3938g oxalic acid, 0.0825gNa 2 WO 4 2H 2 O was added to a beaker containing 100ml of deionized water, so that the molar ratio of W and V in the reactant was 10:100, and the resulting reactant solution was stirred until transparent with a magnetic stirrer, then transferred to a 50ml reaction kettle, filled with The ratio was 0.6, and it was incubated at 190°C for 24 hours. After the reaction was finished, it was naturally cooled to room temperature, and the product was taken out, washed several times with alcohol and deionized water, and then placed in a freeze dryer for low-temperature vacuum drying for 24 hours. Finally, the dried product was taken out and calcined at 600° C. for 3 hours under the protection of argon. The tungsten-doped VO prepared in this embodiment 2 (R) Electron micrographs of nanoparticle raw materials are shown in figure 1 , the x-ray diffraction pattern i...

Embodiment 2

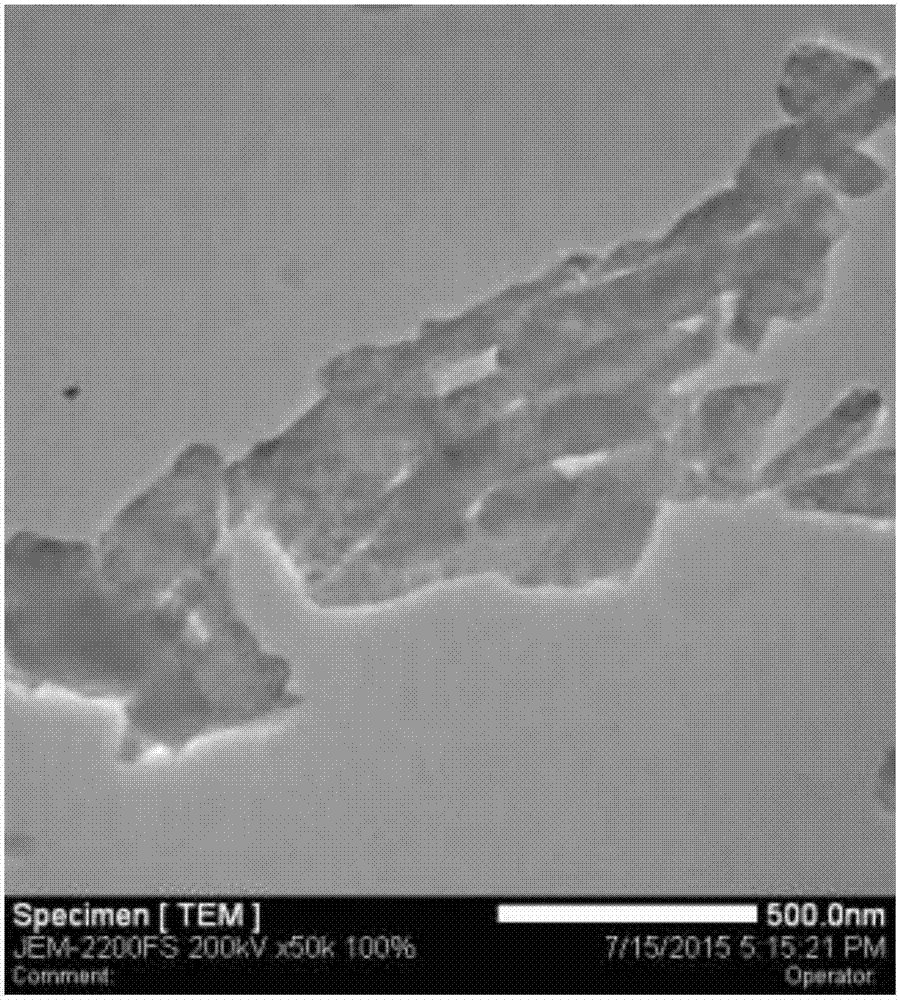

[0023] The rhenium sheet was pre-pressed with a diamond counter-anvil press with an anvil surface of 200 μm, and a hole with a diameter of 100 μm was drilled in the center of the indentation, which was used as a sample cavity for loading raw materials. The tungsten-doped R phase VO that the appropriate amount of embodiment 1 makes 2 Fill the nanoparticle raw materials into the sample chamber, add ruby microspheres as pressure marks (to detect the pressure in the pressure chamber), drop a mixed solution of formazan / ethanol with a volume ratio of 4:1 as the pressure transmission medium, and then seal the pressure chamber. machine for pressurization. When the pressure rises to ~64GPa, and the pressure is released to normal pressure, the Mx' phase VO with metallic characteristics can be obtained 2 nanoparticles. The prepared Mx' phase VO with metallic properties 2 Electron micrographs, X-ray diffraction spectra and infrared spectra of nanoparticles are shown in image 3 , ...

Embodiment 3

[0025] The press, sample chamber and pressure transmission medium are the same as those in Embodiment 2. The tungsten-doped R phase VO that embodiment 1 makes 2 The nanoparticle raw material fills the sample cavity, and then adds ruby microspheres as a pressure mark (to detect the pressure in the pressure cavity), and then seals the press for pressurization. When the pressure rises to ~65.5GPa, and the pressure is released to normal pressure, the Mx' phase VO with metallic characteristics can be obtained 2 Nanoparticles, fabricated Mx' phase VO with metallic properties 2 Infrared spectra of nanoparticles see Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com