Implantation method of steel disc when casting pattern block of tyre mould at high pressure

A technology for casting tires and pattern blocks, which is applied in the field of steel sheet implantation in high-pressure casting tire mold pattern blocks, which can solve the problems of low cost and short production cycle, and achieve the effects of low production cost, convenient implementation, and firm joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

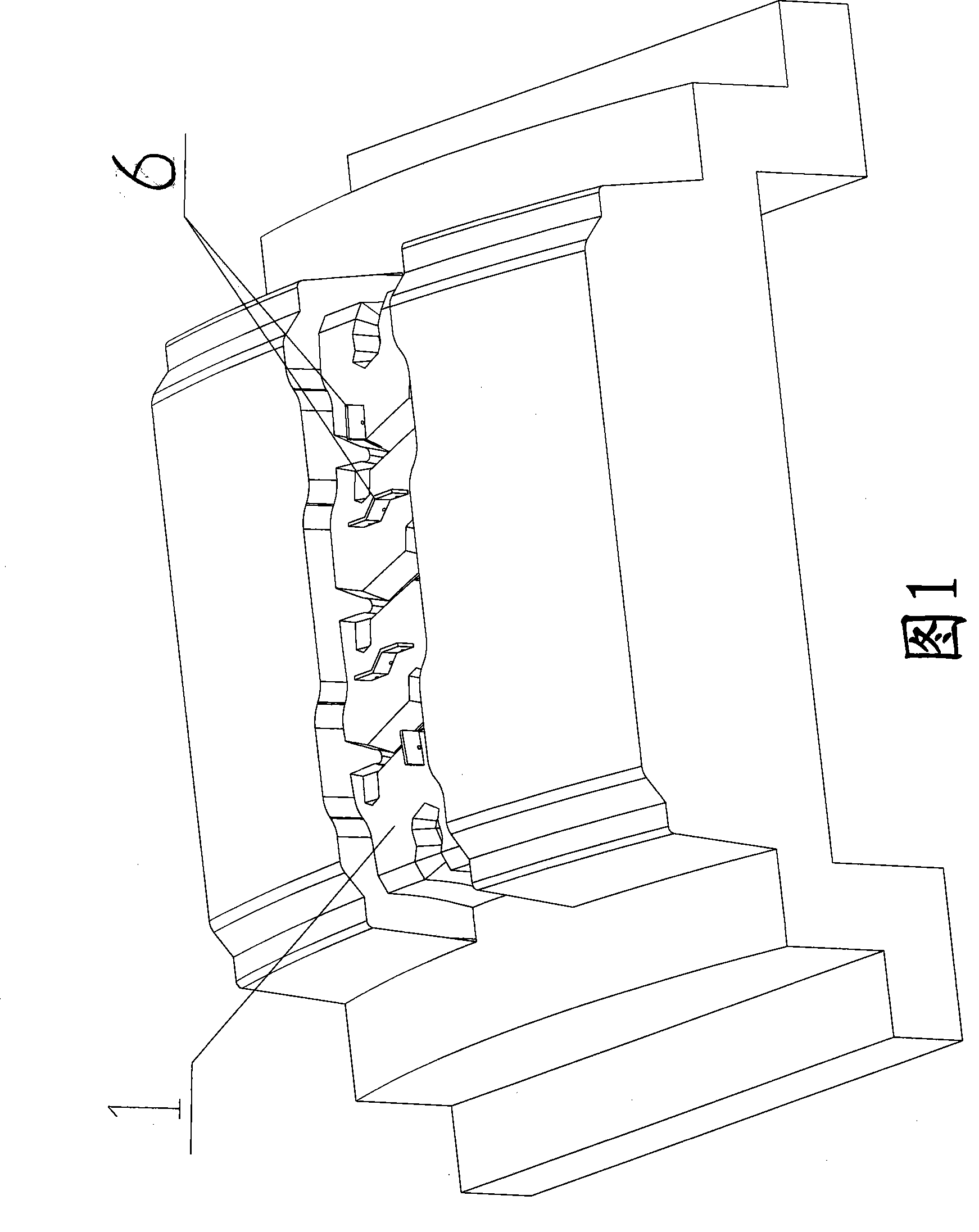

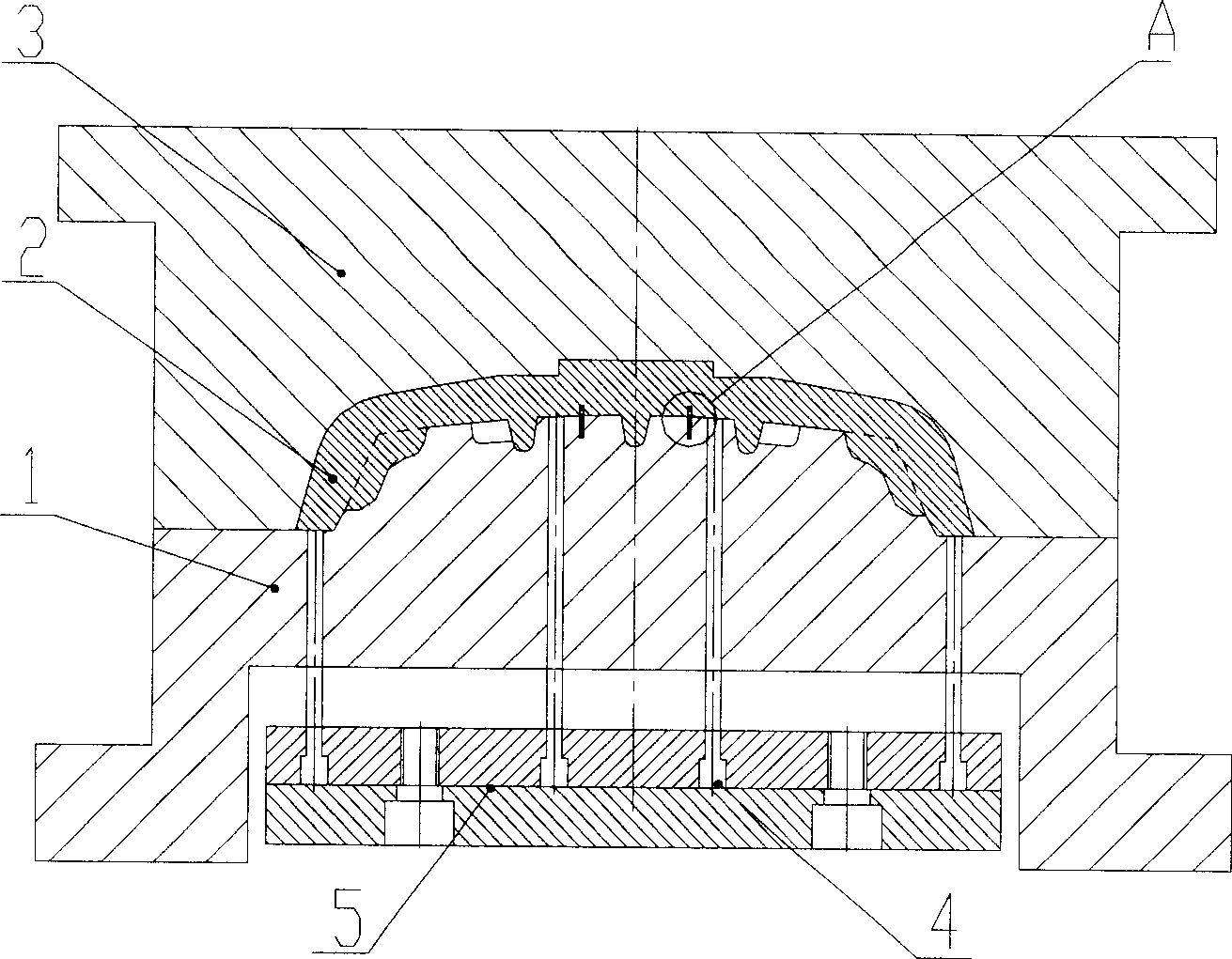

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] The invention utilizes metal molds to high-pressure cast pattern blocks in tire molds, and inserts steel sheets between patterns of the pattern blocks while die-casting the pattern blocks. Steel sheet implantation method among the present invention is as follows:

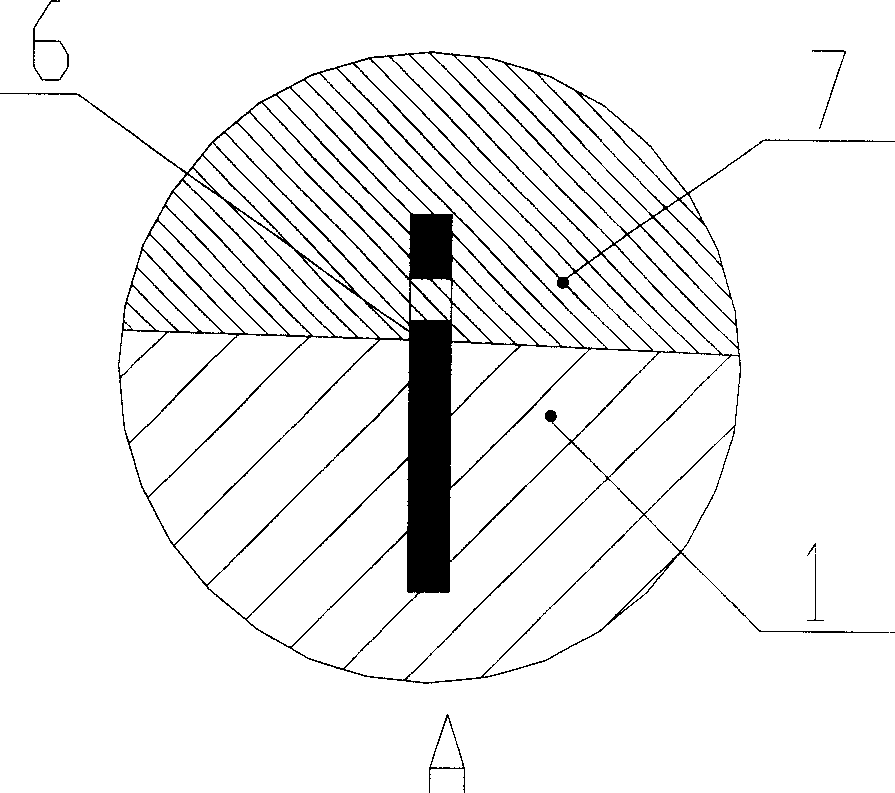

[0018] In the first step, recessed steel sheet grooves are set between the patterns on the upper surface of the lower die 1 . When setting the steel sheet groove, its specific position and size should be determined. When determining the position of the steel sheet groove, since the pattern on the upper surface of the lower mold is consistent with the pattern on the corresponding tire tread, the position of the steel sheet groove can be determined according to the position of the narrow groove on the tire tread. The depth of the narrow groove is the same as the depth of the steel sheet groove, and its len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com