LED structure

A technology of light-emitting diodes and light-emitting chips, which is applied to semiconductor devices of light-emitting elements, light sources, cooling/heating devices of lighting devices, etc., and can solve problems such as poor heat dissipation, fewer light-emitting chips, and inability to apply general lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

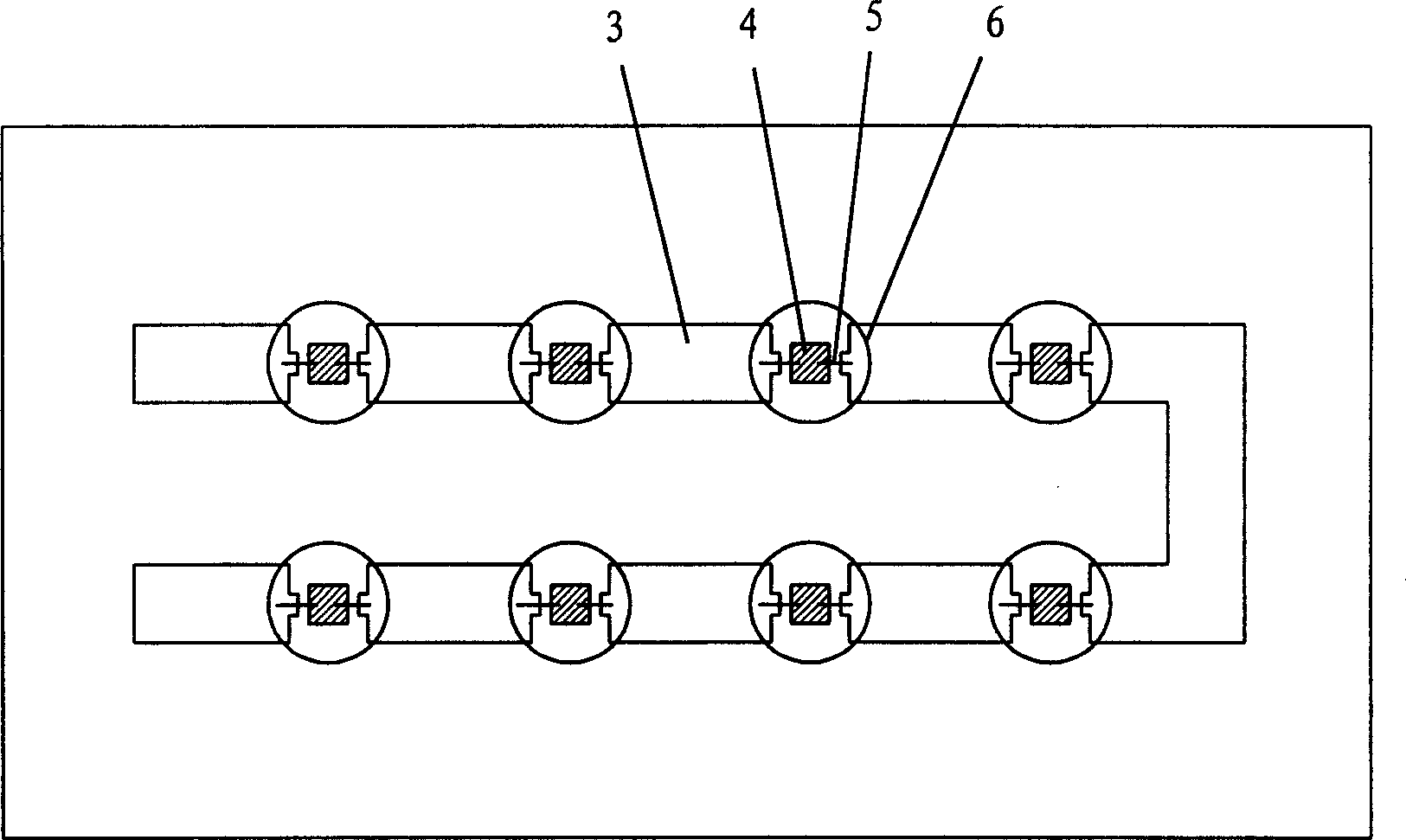

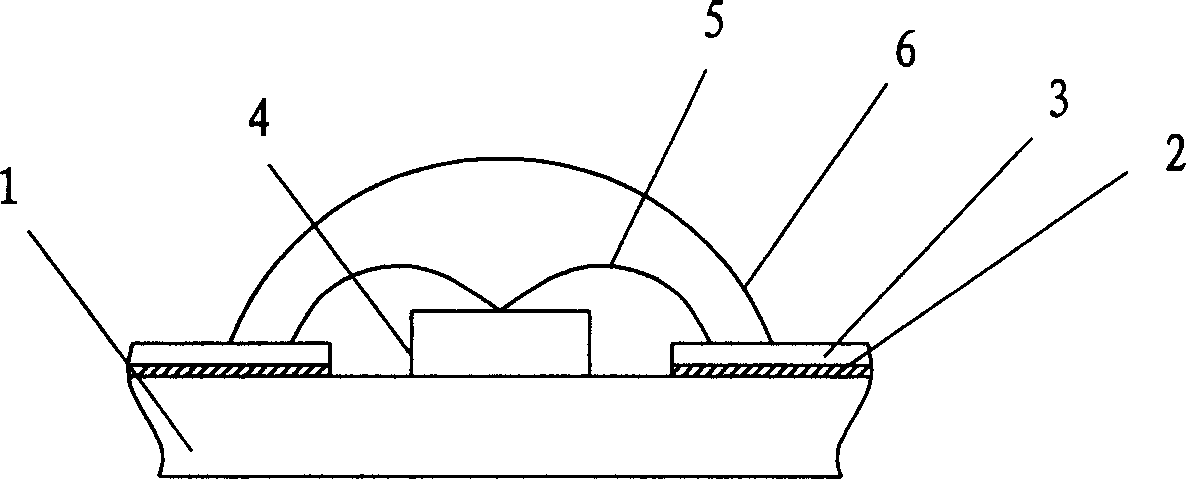

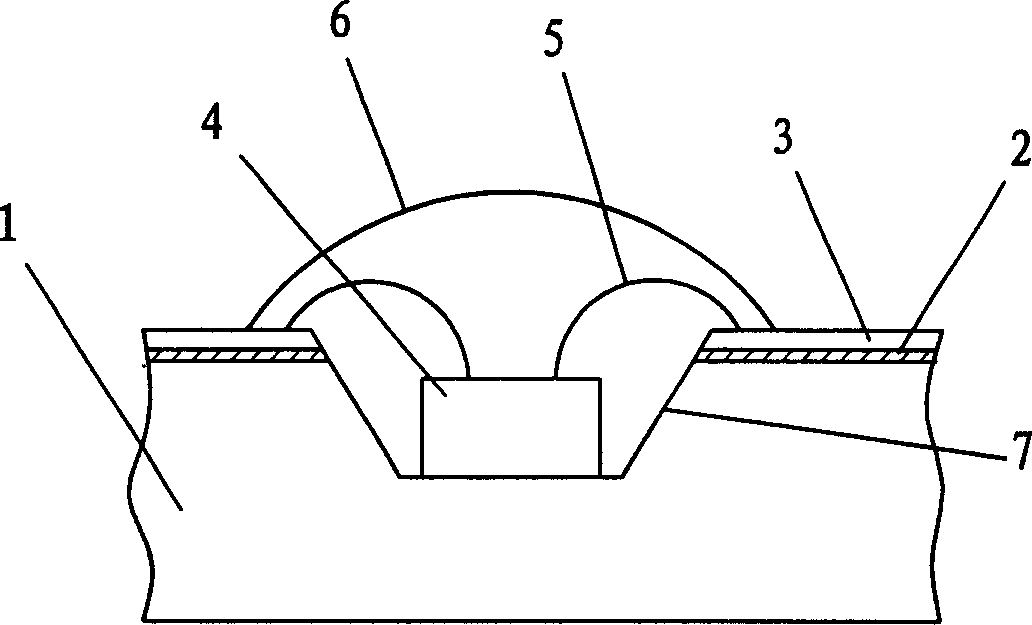

[0025] refer to figure 1 , figure 2 As shown, the light-emitting diode structure includes a heat-conducting substrate 1, and a circuit 3 is arranged on the heat-conducting substrate 1. There is an insulating layer 2 between the heat-conducting substrate 1 and the circuit 3, and more than one light-emitting chip 4 is distributed between the circuits 3. In the space on the substrate 1 , the light-emitting chip 4 is connected to the circuit 3 through the metal wire 5 , and the light-emitting chip 4 is covered with a light-transmitting protective layer 6 .

[0026] The thermally conductive substrate 1 is made of aluminum, copper, and ceramics with good thermal conductivity. Of course, other materials with good thermal conductivity can also be used; the insulating layer 2 should have strong insulating properties, and the circuit 3 covered on the insulating layer 2 can be copper. Foil, by first covering the insulating layer 2 with a layer of copper foil, and then making various re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com