Touch screen, touch display device and production method of touch screen

A manufacturing method and touch screen technology are applied in the field of touch screen manufacturing, touch screen and touch display device, and can solve the problems of affecting the display effect of the touch display device and reducing the light transmittance of the touch screen, so as to improve the macro color effect and improve the light The effect of reducing transmittance and coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to solve the technical problem that the insulating layer exists in a large area in the prior art, which greatly reduces the light transmittance of the touch screen and affects the display effect of the touch display device, the present invention provides a touch screen, a touch display device and a touch screen manufacturing method.

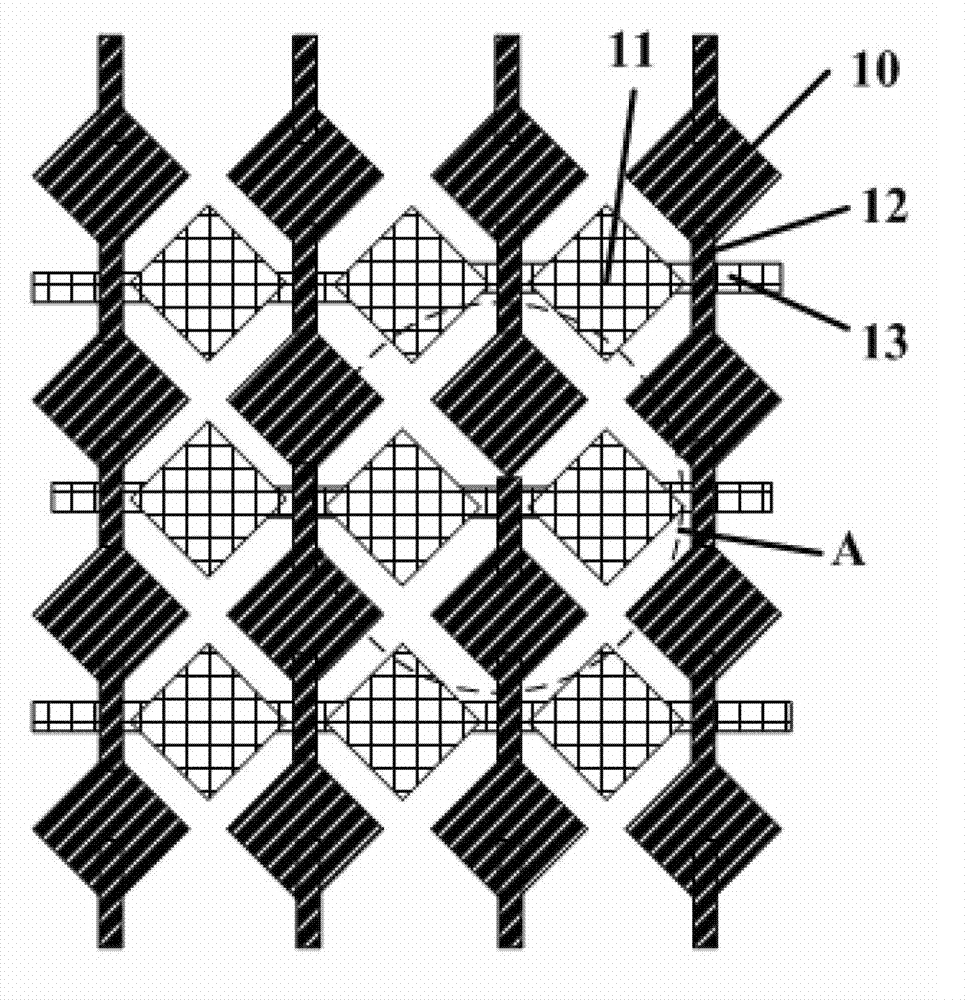

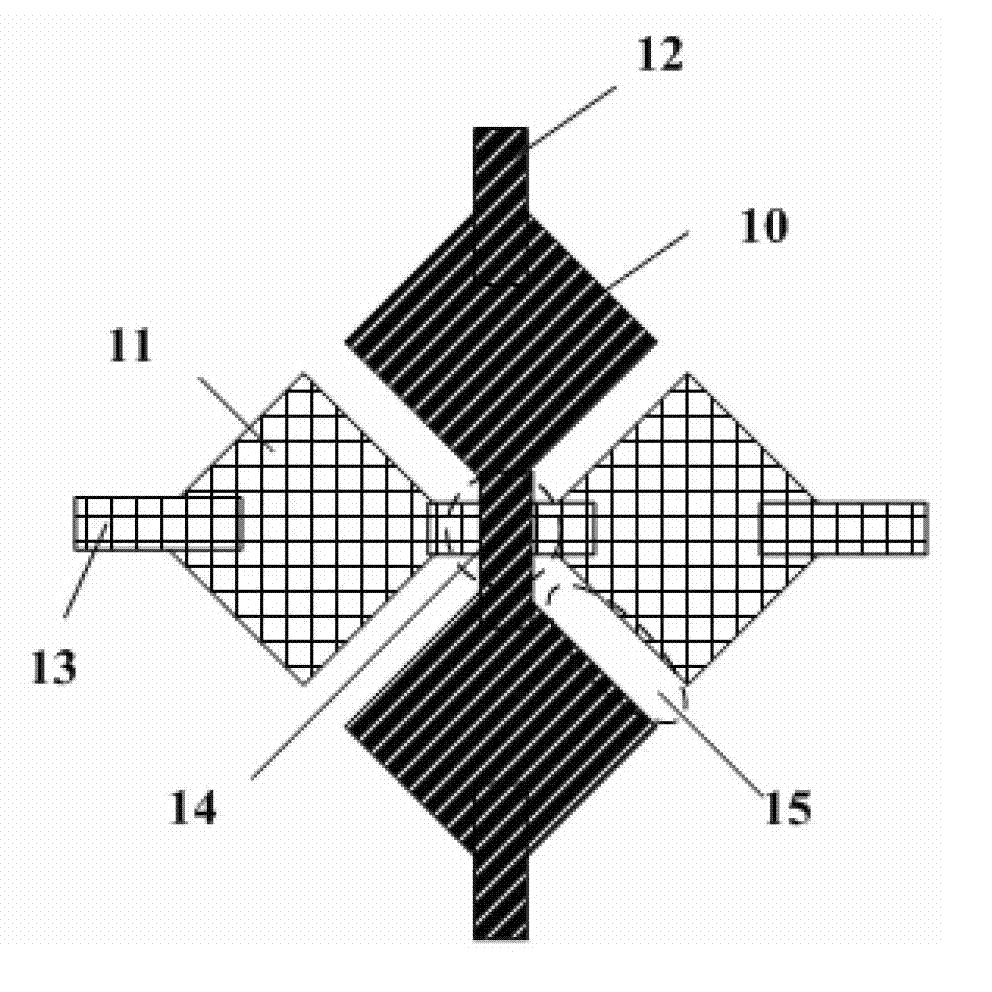

[0047] Such as image 3 As shown, the touch screen of the present invention includes on the transparent substrate:

[0048] The first electrode 10, the second electrode 11 and the second electrode connection line 13 on the first layer, the first electrode 10 and the second electrode 11 are arranged in a cross, and the second electrode connection line 13 connects Adjacent second electrodes 11 are connected;

[0049] The first electrode connecting wire 12 on the second layer overlaps the adjacent first electrodes 10 at the intersection;

[0050] An insulating block 160 located between the first electrode connecting line 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com