Alternated plate feeding device

A technology for feeding devices and plates, applied in the directions of conveyors, transportation and packaging, can solve the problems such as continuous feeding of narrow belt plates, no application in the field of bending machines, poor consistency of processing dimensions, etc., and achieves compact structure, Easy control and small surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

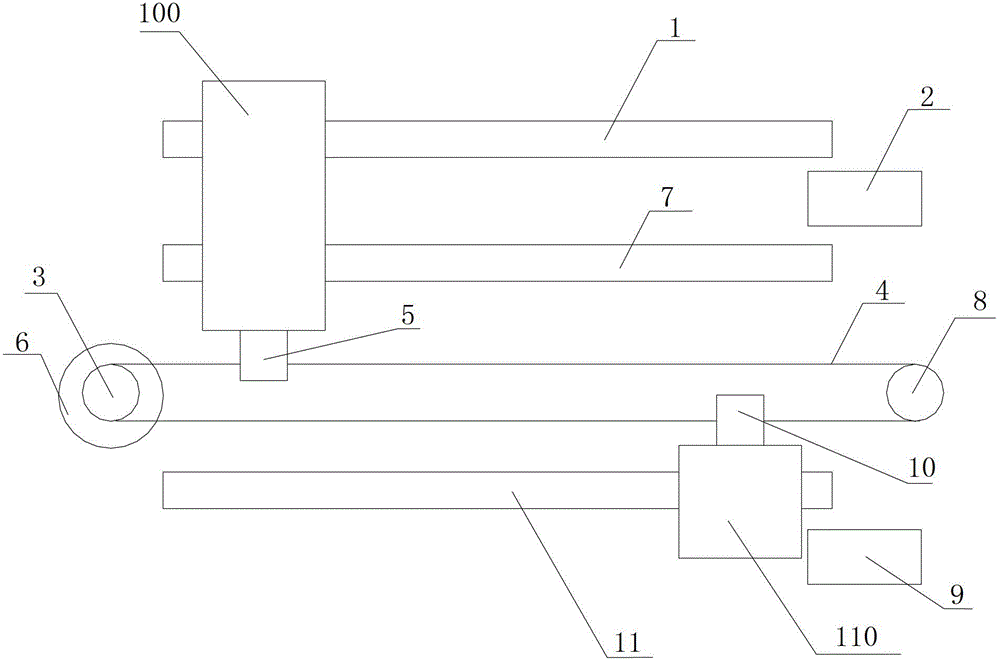

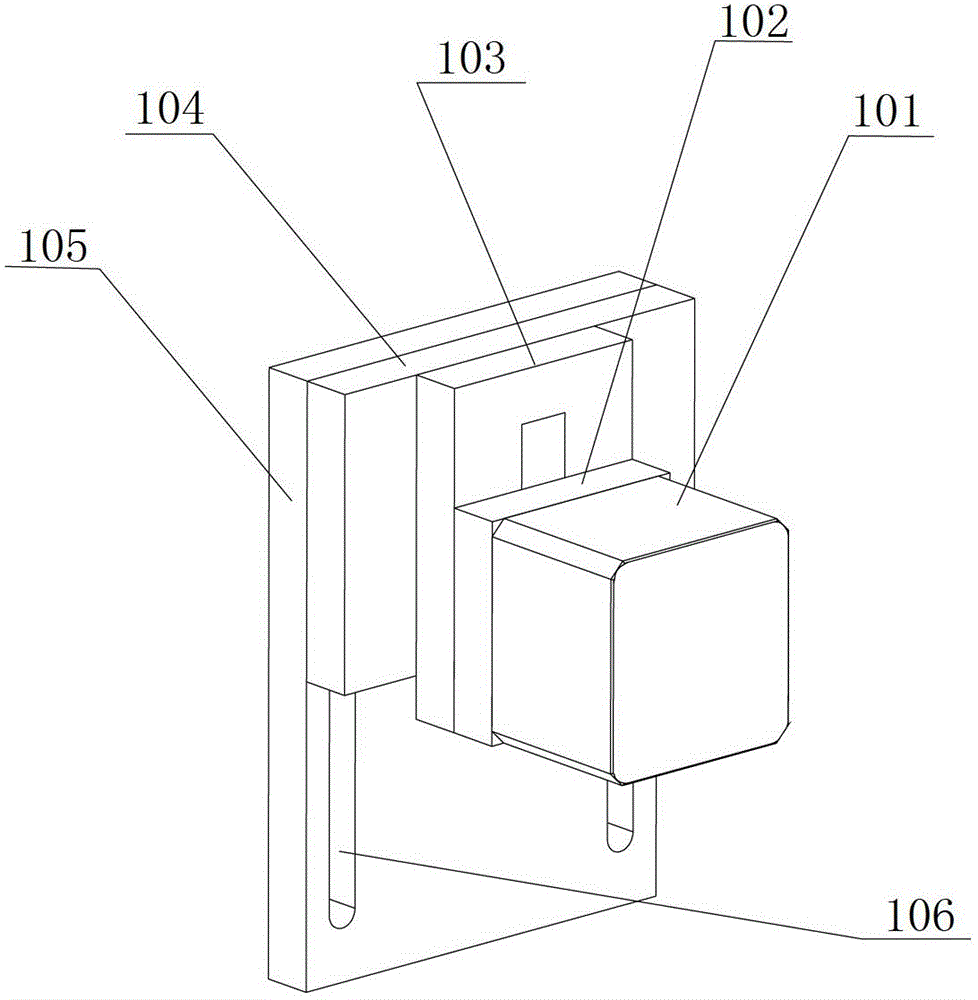

[0026] Such as figure 1As shown, it is the plate alternate feeding device of the present invention, including: a first plate clamping mechanism 100 for clamping plates, a second plate clamping mechanism 110 for clamping plates, slide rails 1, slide rails 7, slide rails Rail 11, conveyor belt 4, motor 6, support roller 3, support roller 8, fixed connector 5, fixed connector 10, limit block 2 and limit block 9, the first plate clamping mechanism 100 and slide rail 1 and slide The rail 7 is slidably matched, and the second plate clamping mechanism 110 is slidably matched with the slide rail 11. One end of the conveyor belt 4 is driven by the motor 6 through the motor shaft to drive the support roller 3, and the other end is provided with the support roller 8. The conveyor belt 4 is wound around the two support rollers. The ring between the support roller 3 and the support roller 8, the position of the conveyor belt 4 between the two support rollers (the support roller 3 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com