High tensile and bend resistant movables cable conductor

A technology for moving cables and cable conductors, applied in conductors, insulated cables, insulated conductors, etc., can solve the problems of lack of bending resistance, easy disconnection of cable conductors, etc., to avoid breaking and bending, and strong bending resistance. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The specific implementation, non-limiting examples are as follows:

Embodiment

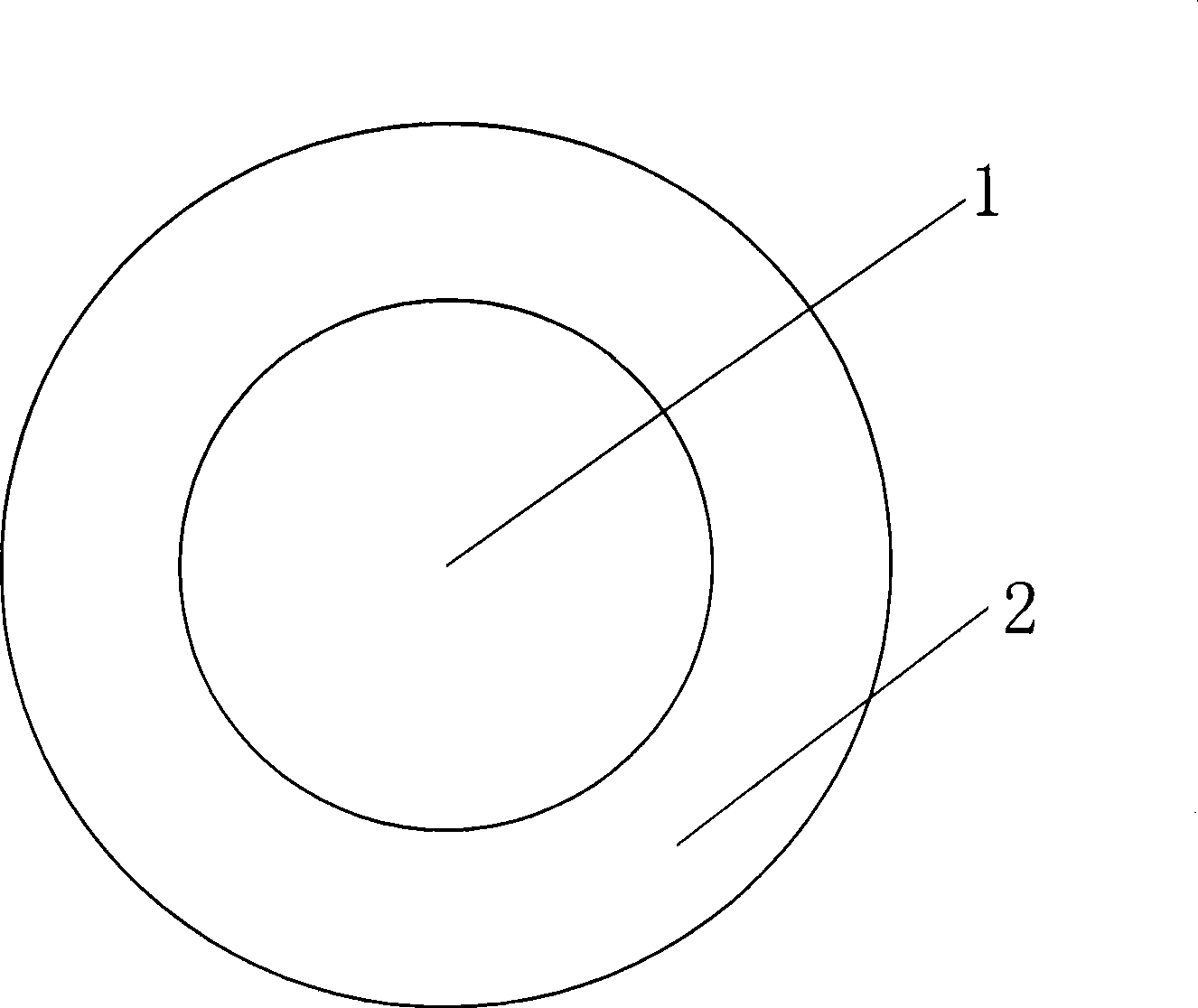

[0017] Example: see figure 1 , the cable conductor of the present embodiment includes, the anti-stretch layer 1 in the inner layer, which is made of multiple strands of high-strength spun yarn fibers twisted and twisted, and the twisted and twisted directions are the same, and its tensile strength The strength is 2 to 5 times that of steel wire, dozens of times that of copper wire, and its elongation is less than 4%, while the elongation of copper wire is about 15 to 25%. Strong bending resistance, suitable for wire drawing of various mobile cable conductors.

[0018] The conductor layer 2 is wound on the anti-drawing layer 1 with thin tinned annealed copper wire or thin annealed copper wire in layers. The winding direction of each layer is opposite from the inside to the outside, and the winding direction of the outermost layer is left. This structural form The pitch is very small, and the length of the conductor monofilament is 1.3 to 1.5 times the original length. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com