Novel magnetically-grafted silk fiber and preparation method thereof

A silk fiber and magnetic technology, which is applied in fiber processing, animal fiber, textiles and papermaking, etc., can solve the problems of durability improvement and achieve the effect of retaining luster and high far-infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

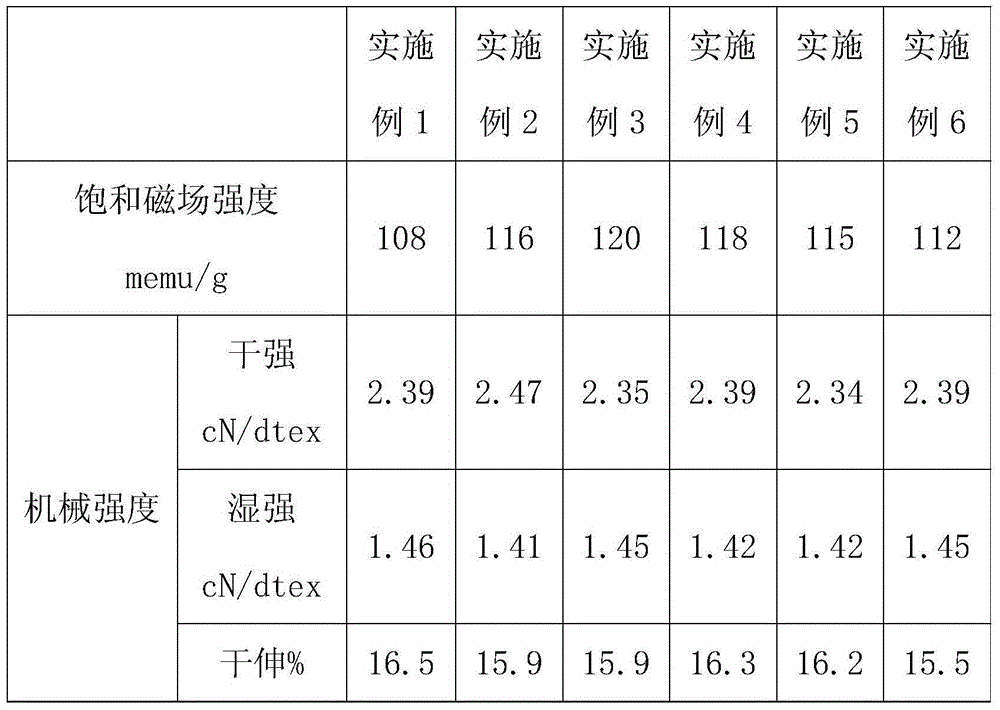

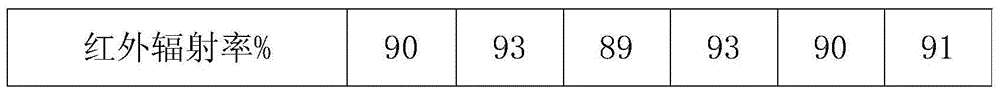

Examples

Embodiment 1

[0026] The particle size is 200-300nm containing modified Fe 3 o 4 and AgNO 3 The magnetic nanomaterials were added to the phosphate buffer solution, ultrasonically treated at 50°C for 35 minutes, and glucose, sodium hydroxide and modified silicone oil were added, and stirred evenly to obtain a stable blend solution, in which Fe 3 o 4 The concentration is 3g / L, Ag + The concentration is 4g / L, the volume fraction of glucose and sodium hydroxide is 5%, the volume fraction of modified silicone oil is 5%, then add cerium ammonium nitrate with a volume fraction of 1%, and stir at room temperature to obtain a magnetic grafting liquid.

[0027] After the mulberry silk is removed with deionized water to remove surface impurities, it is degummed with a weak alkaline solution, washed and dried to obtain surface-activated silk fibers, and the surface-activated silk fibers are added to soak in the magnetic grafting solution, and the bath ratio is 1: Heating and shaking at 40 and 50°C ...

Embodiment 2

[0029] The particle size is 200-300nm containing modified Fe 3 o 4 and AgNO 3 The magnetic nanomaterials were added to potassium persulfate buffer solution, ultrasonically treated at 60°C for 25 minutes, glucose, sodium hydroxide and modified silicone oil were added, and the blend was uniformly stirred to obtain a stable blend solution, in which Fe 3 o 4 The concentration is 5g / L, Ag + The concentration is 6g / L, the volume fraction of glucose and sodium hydroxide is 8%, the volume fraction of modified silicone oil is 10%, then add cerium ammonium nitrate with a volume fraction of 2%, and stir at room temperature to obtain a magnetic grafting liquid.

[0030] After the tussah silk is removed with deionized water to remove surface impurities, it is degummed with a weak alkaline solution, washed and dried to obtain surface-activated silk fibers, and the surface-activated silk fibers are added to soak in the magnetic grafting solution, and the bath ratio is 1: Heating and shak...

Embodiment 3

[0032] The particle size is 200-300nm containing modified Fe 3 o 4 and AgNO 3 The magnetic nanomaterials were added to the phosphate buffer solution, ultrasonically treated at 55°C for 30 minutes, and glucose, sodium hydroxide and modified silicone oil were added, and stirred evenly to obtain a stable blend solution, in which Fe 3 o 4 The concentration is 4g / L, Ag + The concentration is 5g / L, the volume fraction of glucose and sodium hydroxide is 6%, the volume fraction of modified silicone oil is 8%, then add cerium ammonium nitrate with a volume fraction of 1.5%, and stir at room temperature to obtain a magnetic grafting liquid.

[0033] Use deionized water to remove impurities on the surface of regenerated silk fibers, degumming with weak alkaline solution, wash and dry to obtain surface-activated silk fibers, add surface-activated silk fibers to soak in magnetic grafting liquid, bath ratio is 1 : 40, 55 DEG C of heating and oscillating reaction for 1.5h, taking out, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com