Electroplating clamp for printed circuit board (PCB)

A technology for printed circuit boards and electroplating fixtures, applied in the electrolytic process, electrolytic components, etc., can solve the problems of affecting efficiency, affecting the uniformity of electroplating, damage to the plated parts, etc., to improve production efficiency, avoid fixing methods, and improve good quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure of the printed circuit board electroplating jig of the present invention will be described below with reference to the accompanying drawings.

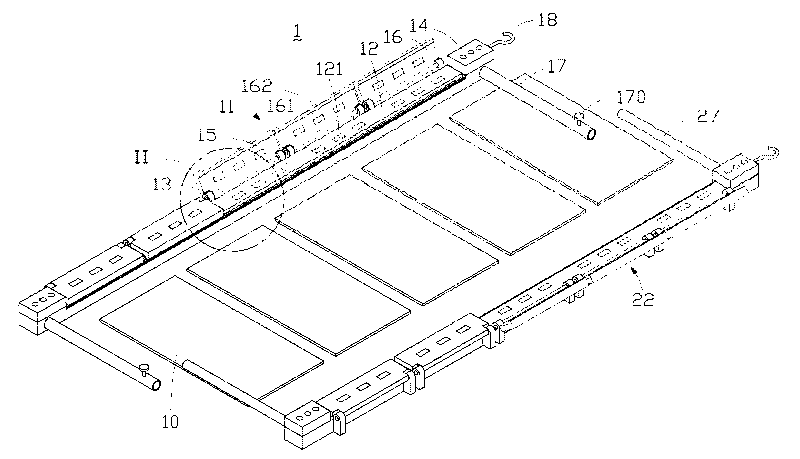

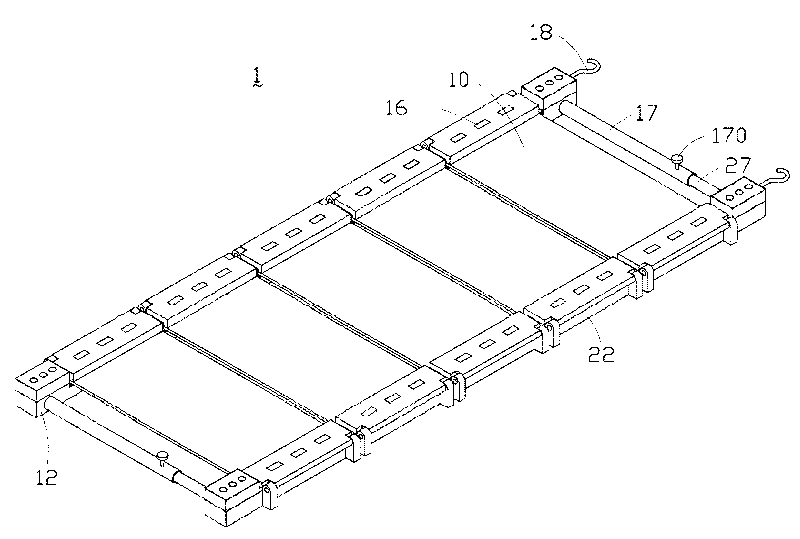

[0025] see figure 1 , is an exploded schematic diagram of a three-dimensional structure of a preferred embodiment of the printed circuit board electroplating jig of the present invention. The printed circuit board electroplating jig 1 is mainly used to clamp components to be electroplated, such as the printed circuit board 10 , and can also be used to clamp other suitable components to be electroplated. The printed circuit board electroplating jig 1 includes a first clamping part 11 and a second clamping part 22 .

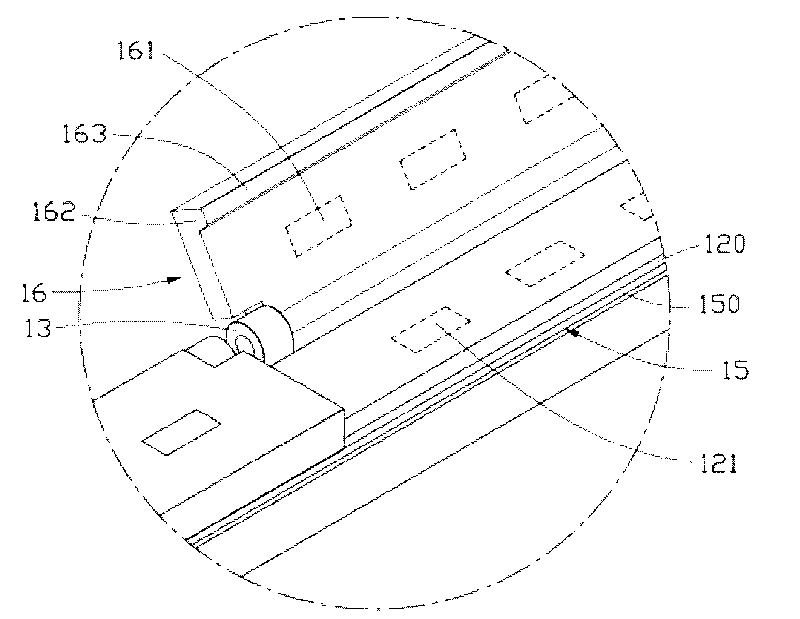

[0026] The first clamping part 11 includes a main body 12 , a pivot 13 , a fixed end 14 , an electrode 15 , a clamping cover 16 , a sleeve 17 and a hook 18 . The main body 12 , the pivot 13 , the fixed end 14 and the clamping cover 16 are made of rigid insulating material, such as polycarbonate (Polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com