Yoga rod and manufacturing method thereof

A technology of yoga sticks and mandrels, applied in the field of fitness, can solve the problems of complex manufacturing process of yoga sticks, reduce work efficiency, increase work costs, etc., achieve the effect of reducing work costs, improving work efficiency, and not easy to loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Yoga stick of the present invention is prepared by following preparation method, wherein, preparing mandrel 2 comprises the steps:

[0039] A. Mix high-pressure low-density polyethylene (LDPE) resin 100, foaming nucleating agent 0.2-10 and pigment 0.1-10 evenly, then add plasticizer and stir;

[0040] B. Plasticize in a foaming machine at 170°C-250°C for 3-10 minutes, then inject the sizing agent through the high-pressure reciprocating pump of the metering plunger, and then inject butane gas through the high-pressure reciprocating pump of the metering plunger for foaming. 70 ℃ - 95 ℃ foaming machine uniformly mixed into a mixture;

[0041]C. The mandrel 2 is extruded and foamed through the die opening of the die head at 80°C-120°C, and cut to length when it is stably cooled to 10°C-50°C to obtain mandrels 2 of different lengths, Then the mandrel 2 is placed under natural conditions to harden.

[0042] Yoga stick of the present invention is prepared by the following pr...

Embodiment 1

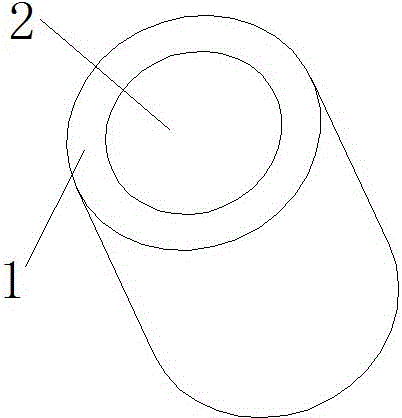

[0050] As an embodiment of the present invention, such as figure 1 Shown, a kind of yoga stick, comprises casing 1 and the core rod 2 that is arranged in casing 1, and described casing 1 is hollow cylindrical structure, and described core rod 2 is nested in casing 1, and described casing 1 and Mandrel 2 is an interference fit. In this embodiment, preferably, the jacket 1 is an EPE foam, and the mandrel 2 is an EPE foam.

[0051] In this embodiment, the yoga stick is made of the following raw materials in parts by mass: polyethylene (LDPE) resin 100, foam nucleating agent 0.2, plasticizer 3, sizing agent 3, foaming agent and pigment 5.

[0052] In this embodiment, the foaming nucleating agent is selected from talcum powder.

[0053] In this embodiment, the plasticizer is selected from dioctyl phthalate, dibutyl phthalate, one or a mixture of two.

[0054] In this embodiment, the styling agent is selected from monoglycerides.

[0055] In this embodiment, the blowing agent is...

Embodiment 2

[0070] As an embodiment of the present invention, such as figure 1 Shown, a kind of yoga stick, comprises casing 1 and the core rod 2 that is arranged in casing 1, and described casing 1 is hollow cylindrical structure, and described core rod 2 is nested in casing 1, and described casing 1 and Mandrel 2 is an interference fit. In this embodiment, preferably, the jacket 1 is an EPE foam, and the mandrel 2 is an EPE foam.

[0071] In this embodiment, the yoga stick is made of the following raw materials per unit mass: polyethylene (LDPE) resin 100, foaming nucleating agent 0.2-10, plasticizer 0.2-5, sizing agent 1-5, foaming agent Agents and pigments 0.1-10.

[0072] In this embodiment, the foaming nucleating agent is selected from talcum powder.

[0073] In the present embodiment, the plasticizer is selected from butyl benzyl phthalate, diphenyl-octyl phosphate, cresyl diphenyl phosphate, epoxy soybean oil, epoxy fatty acid butyl ester, epoxy fatty acid octyl One or more mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com