Fan blade

A technology of fan blades and fan blades, which is applied in the field of fan blades and can solve the problems of personal injury, breakage, and heavy weight of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

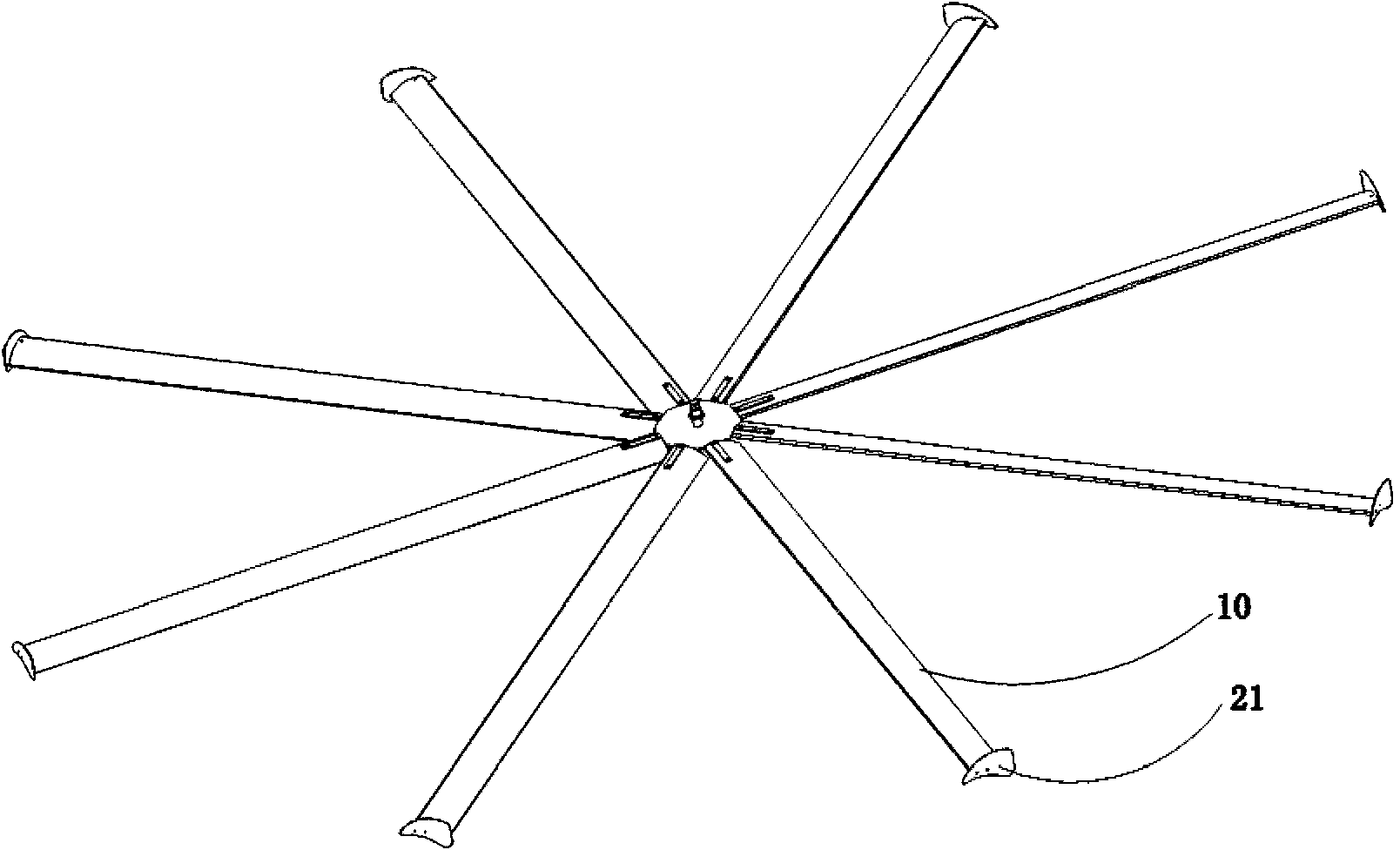

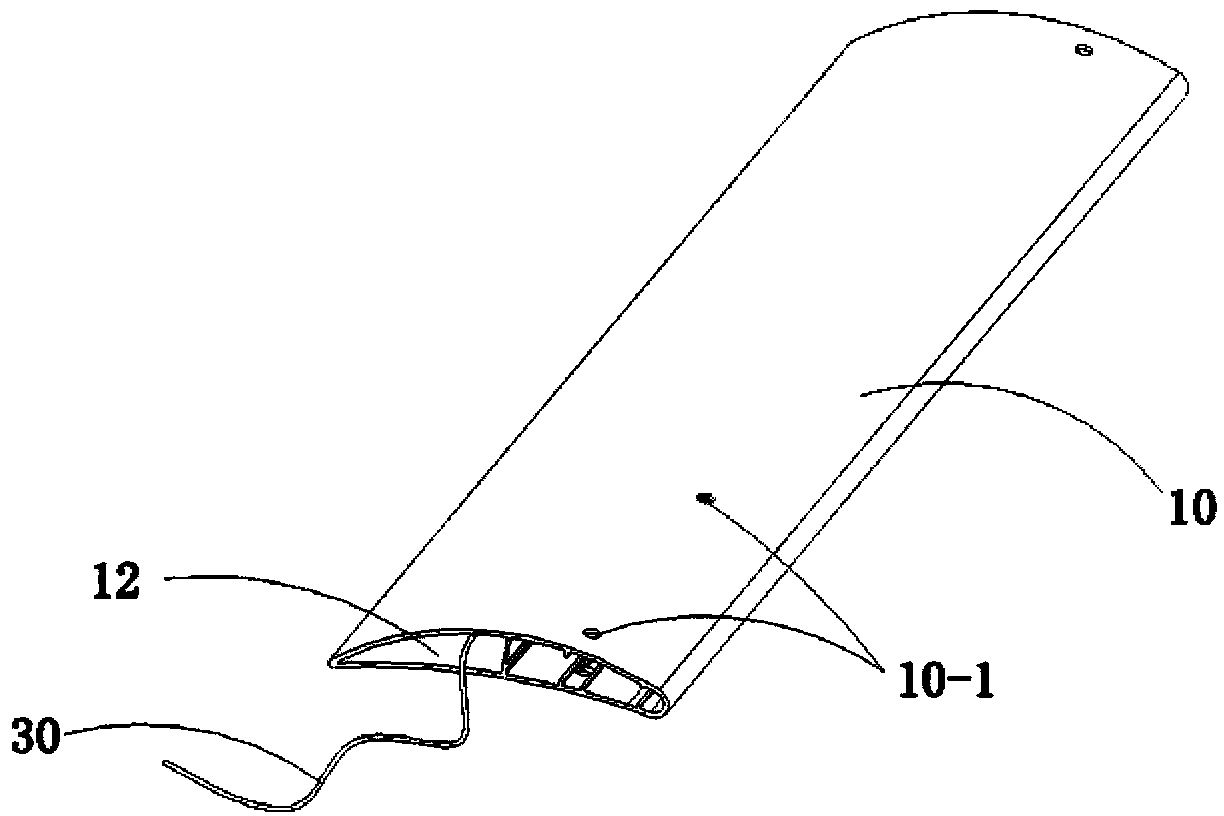

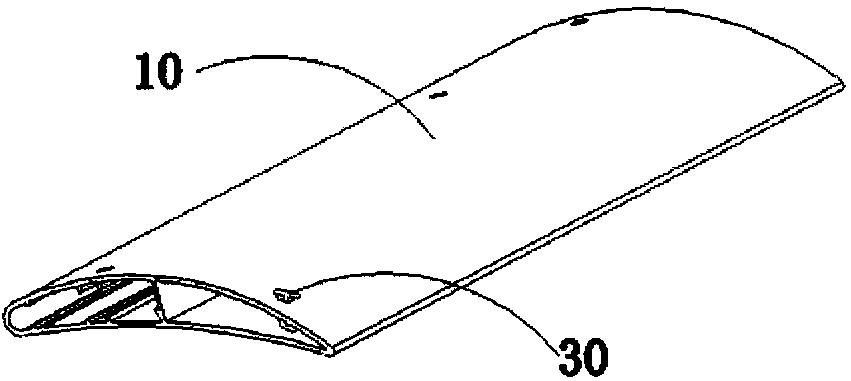

[0021] Such as Figure 1 to Figure 7 The fan blade shown has a blade body 10, the blade body 10 is elongated, and the blade body 10 has a cavity 12 inside, and the cavity 12 extends along the length direction of the blade body 10 and runs through it. Two ends of the fan blade body 10 .

[0022] The cavity 12 is provided with several pairs of ribs (14, 15) on the upper and lower sides of the head of the fan blade body 10, each of the ribs (14, 15) is provided with a gap 14-1, and each of the ribs (14, 15) is provided with a gap 14-1. The notches face each other to form a clamping space 11 for clamping a plate-shaped object. The blade body 10 is provided with a plurality of installation through holes 10 - 1 on the upper and lower walls of the clamping space 11 . In fact, each pair of convex ribs (14, 15) can be butted to form a rib to increase the strength of the fan blade, and the gap 14-1 can be reinforced by a platform extending outward from the side of the rib and Rib side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com