Press-in type high thermal conductive printed circuit board (PCB) and manufacture method thereof

A technology for a PCB board and a manufacturing method is applied in the field of press-in type high thermal conductivity PCB board and its manufacturing, which can solve the problems of looseness, falling off, and weak connection of copper blocks, and achieves the advantages of not easy to loose, realizing electrical connection, and shortening the process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

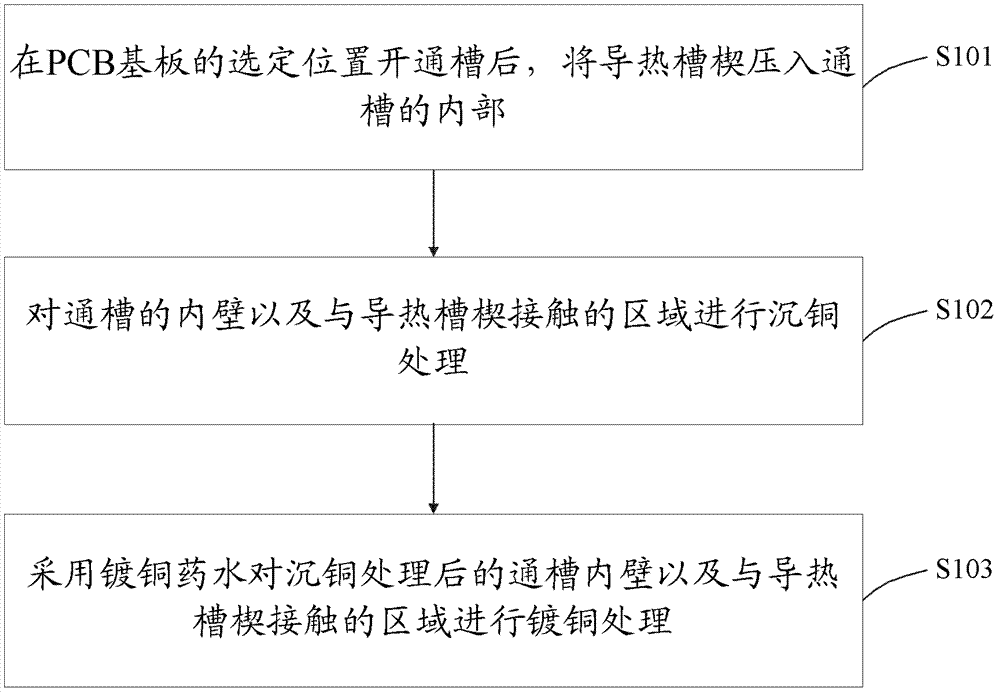

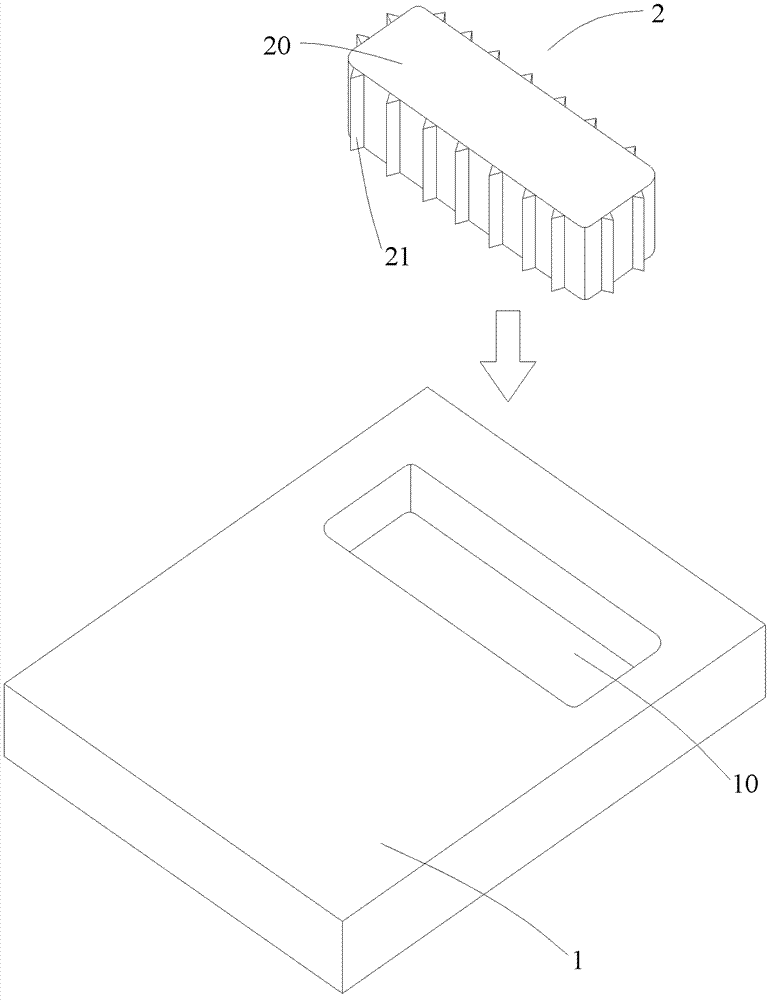

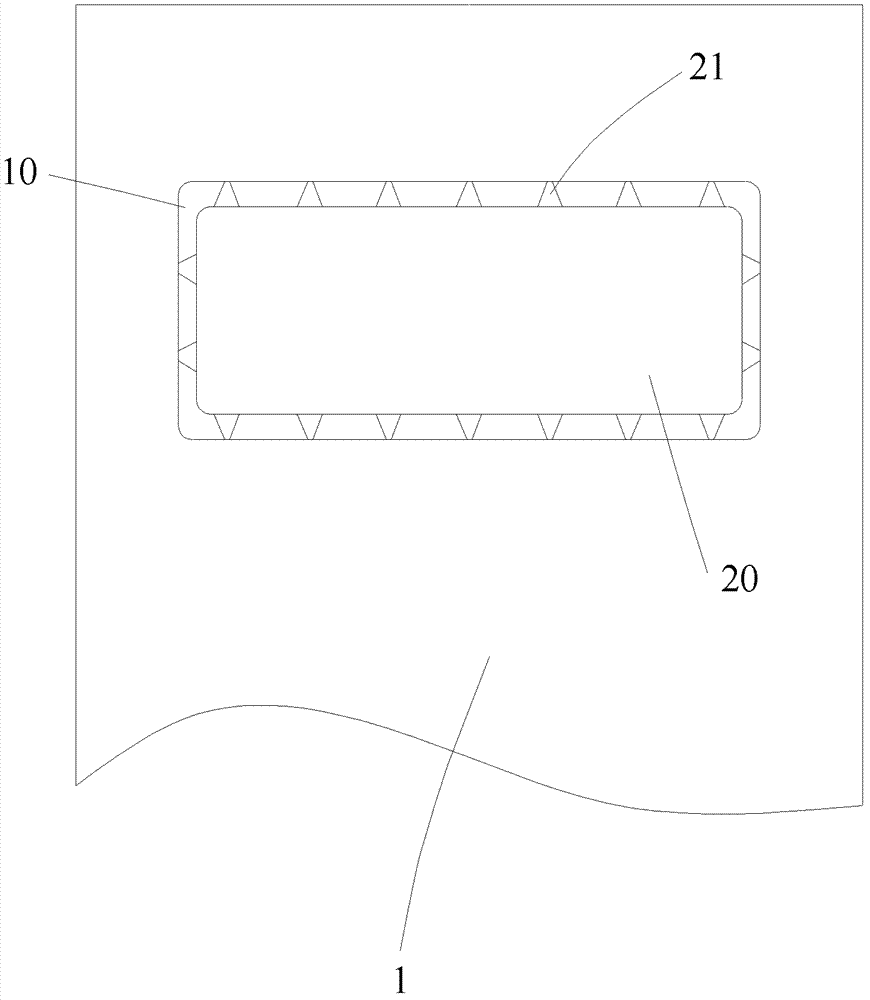

[0031] In the background technology, the process flow of making high thermal conductivity PCB board is long, and since the pressed-in copper block is rigidly connected to the groove wall of the through groove of the PCB substrate, the connection between the pressed-in copper block and the PCB substrate is not firm. , During copper sinking and copper plating, it is easy to cause the pressed copper block to loosen or even fall off. The embodiment of the present invention not only shortens the process flow of making high heat conduction PCB boards, but also makes the heat conduction The slot wedge is fixed in the through slot and is not easy to loose; and because the copper plating solution with high copper and low acid configuration is used to plate copper on the inner wall of the through slot after copper sinking treatment and the area in contact with the heat conduction slot wedge, the copper plated It can tightly wrap the contact point between the heat conduction wedge and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com