Remote-network signature apparatus

A remote network and seal technology, applied in printing, stamping and other directions, can solve problems such as inability to stamp authority and usage management and control, time delay, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

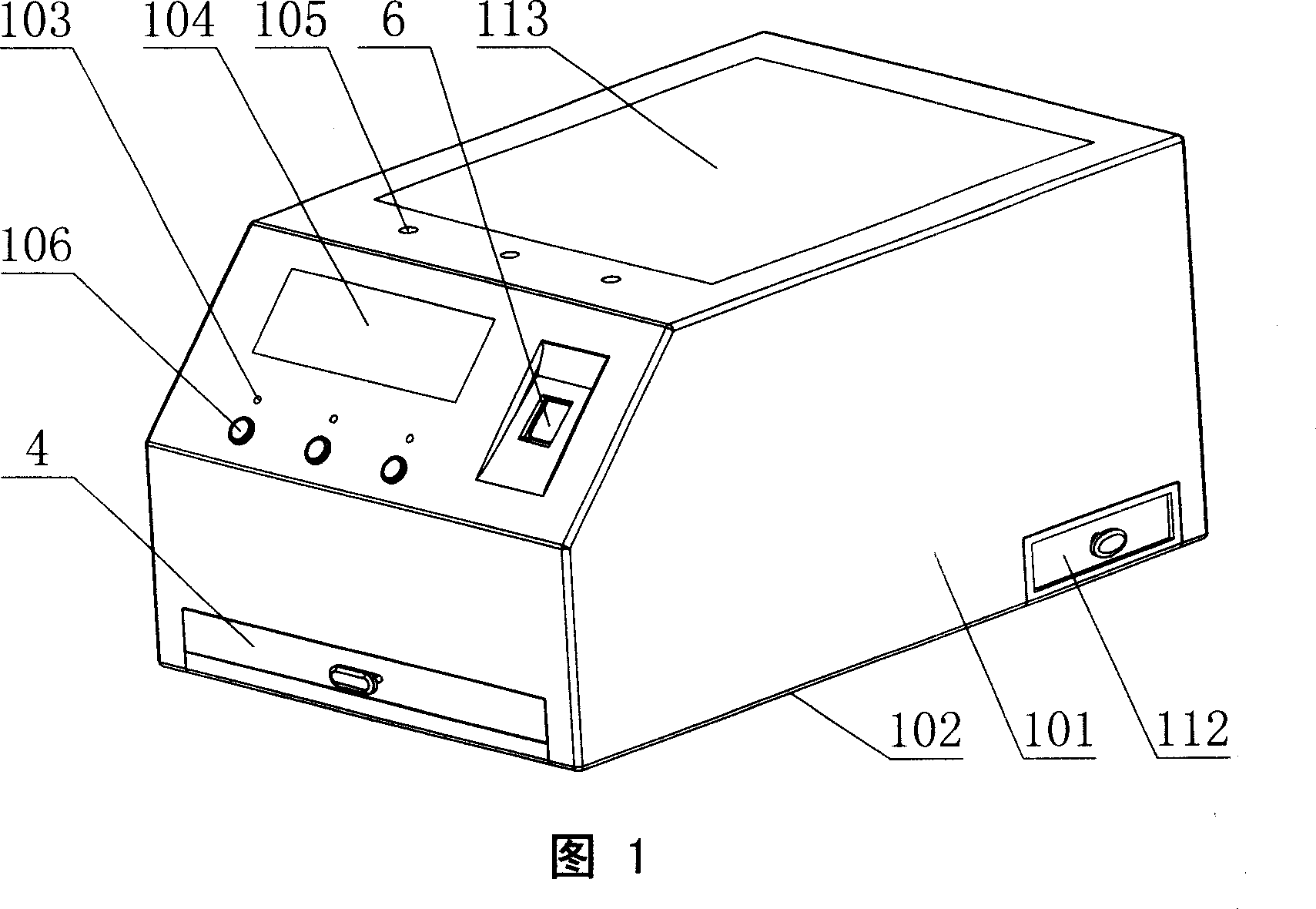

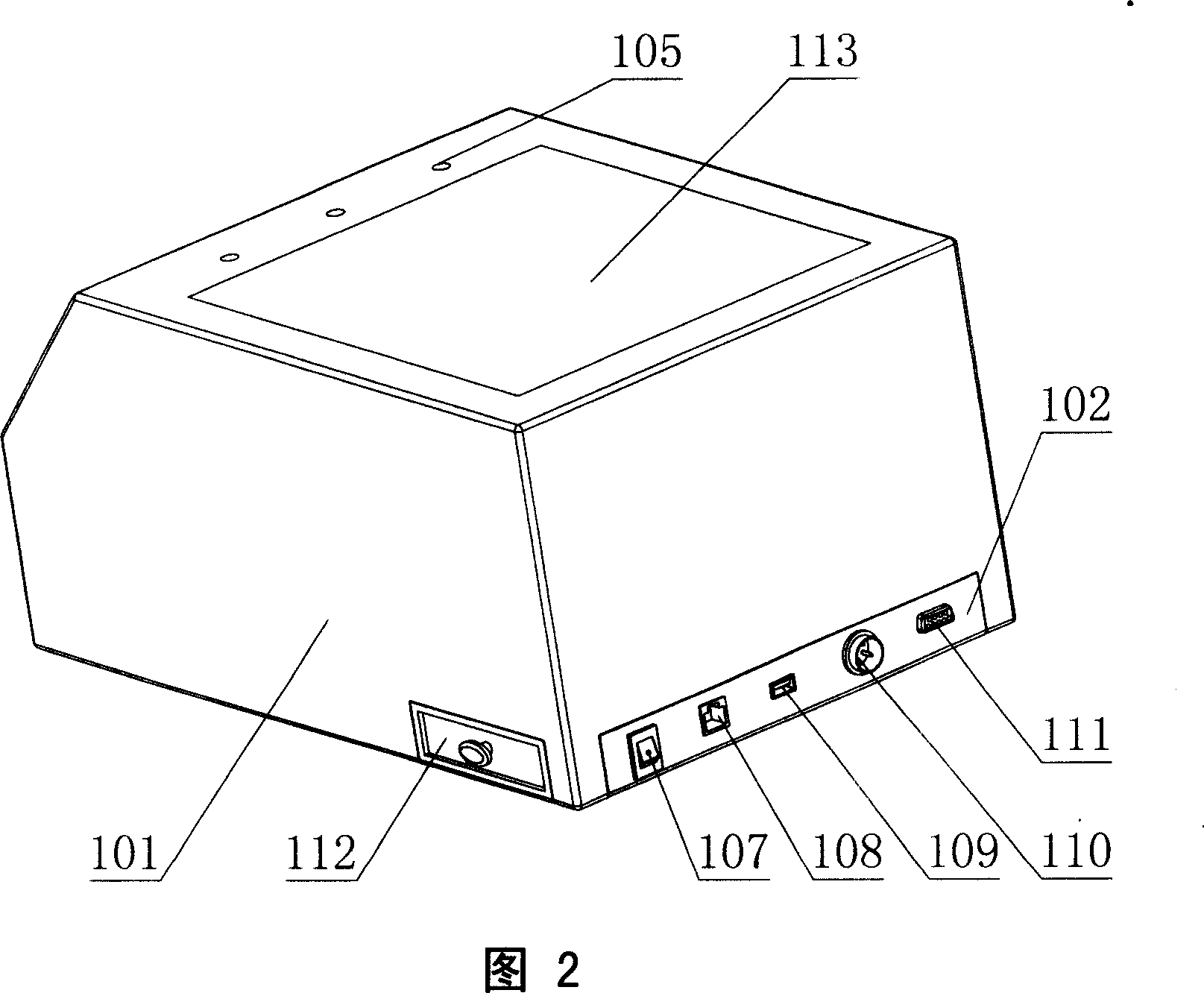

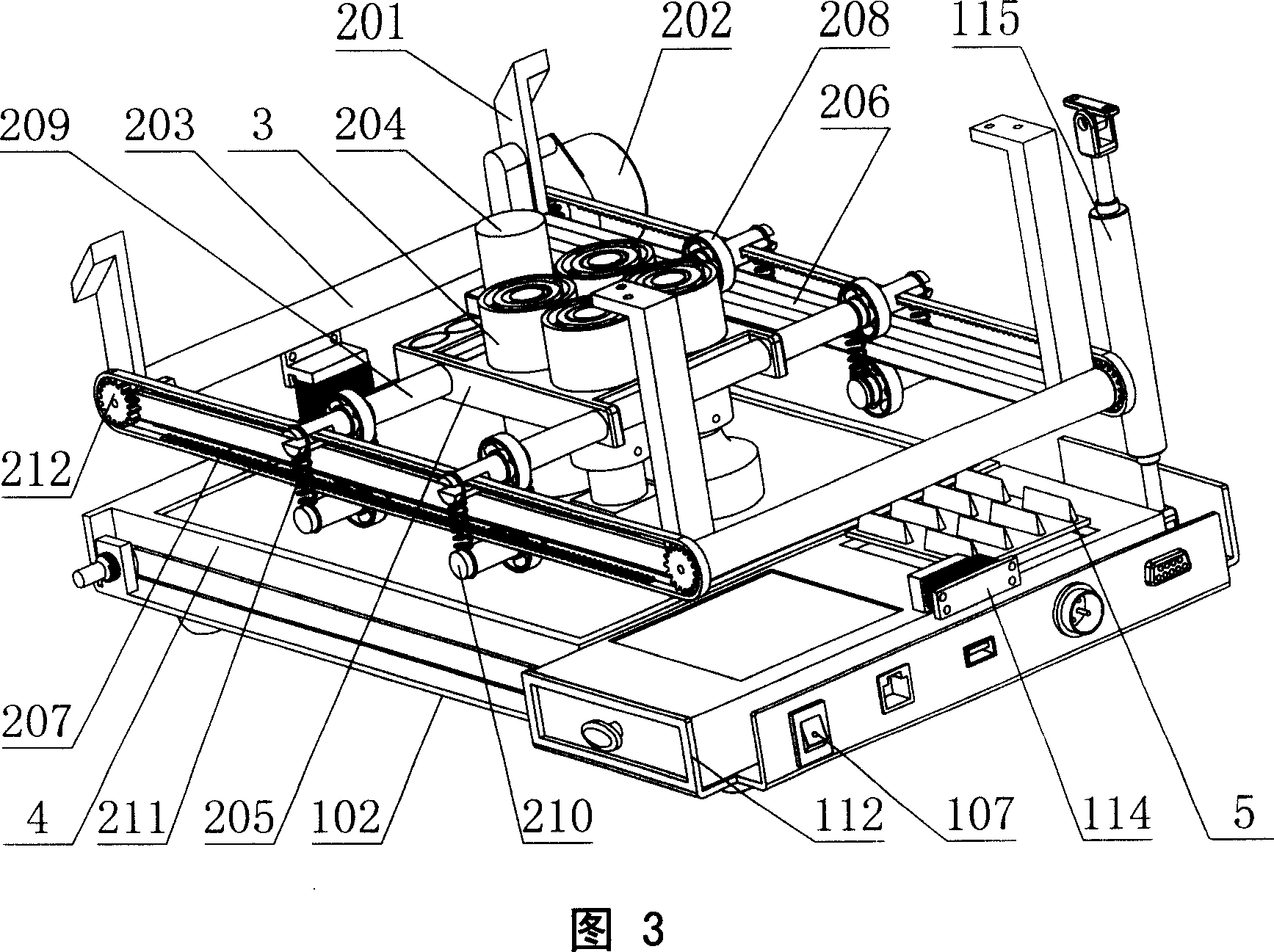

[0057] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 10, Fig. 16 and Fig. 19, the present invention includes a chassis device, a stamp moving device, a stamp holding device 3, a file tray device 4, and a stamp destruction Device 5, operation authority recognizer 6, projector 7, camera 8, control circuit, described chassis device comprises loam cake 101, base 102, ink pad box 112, liquid crystal display 104, voice alarm, voice indicator light 105, operation Button 106, operation status indicator light 103, hydraulic cylinder 115, interface device, the upper cover 101 and the base 102 are airtightly connected through the electromagnet lock 114, so as to prevent the upper cover 101 and the base 102 from being opened illegally , the stamp moving device and the stamp holding device 3 are all arranged in the space enclosed by the upper cover 101 and the base 102, and the hydraulic cylinder 115 connects the upper cover 101 and the base 102 to It is convenient to open the u...

Embodiment 2

[0063] As shown in Figure 1, Figure 2, Figure 6, Figure 7, Figure 8, Figure 11, Figure 12, Figure 17, Figure 18, and Figure 19, the differences between this embodiment and Embodiment 1 are:

[0064] Described stamp moving device comprises fixed support 201, longitudinal driving mechanism, transverse driving mechanism, mobile support 205, and described seal clamping device 3 is fixed on the described mobile support 205, and described vertical driving mechanism is connected with described fixed support 201. connected, the longitudinal drive mechanism includes a longitudinal motor 202, an I longitudinal guide rail 215, and an II longitudinal guide rail 217. The I longitudinal guide rail 215 and the II longitudinal guide rail 217 are parallel to each other and connected with the fixed bracket 201. The longitudinal The output shaft of the motor 202 is fixedly connected to the III gear 220, the I longitudinal guide rail 215 is smooth and cylindrical, the II longitudinal guide rail 21...

Embodiment 3

[0070] As shown in Fig. 1, Fig. 2, Fig. 9, Fig. 13, Fig. 14, Fig. 15, Fig. 16, and Fig. 19, the differences between this embodiment and the first embodiment are:

[0071] Described stamp moving device comprises fixed support 201, longitudinal driving mechanism, transverse driving mechanism, mobile support 205, and described seal clamping device 3 is fixed on the described mobile support 205, and described vertical driving mechanism is connected with described fixed support 201. connected, the longitudinal drive mechanism includes a longitudinal motor 202, an I longitudinal guide rail 215, and a longitudinal lead screw 227, and the I longitudinal guide rail 215 and the longitudinal lead screw 227 are parallel to each other and connected with the fixed bracket 201, the longitudinal The motor 202 is fixedly connected to the fixed bracket 201, the output shaft of the longitudinal motor 202 is fixedly connected to the longitudinal lead screw 227, and the transverse drive mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com