High-speed photographic apparatus component and vehicle exemption label self-service issuing machine

A high-speed instrument and component technology, which is applied in the direction of instruments, electrical components, and instrument-controlled coin-operated equipment, can solve the problems of not promoting the use of self-service machines in large quantities, increasing the labor intensity of operators, and having too many government workers. , to achieve the effect of facilitating business processing, improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

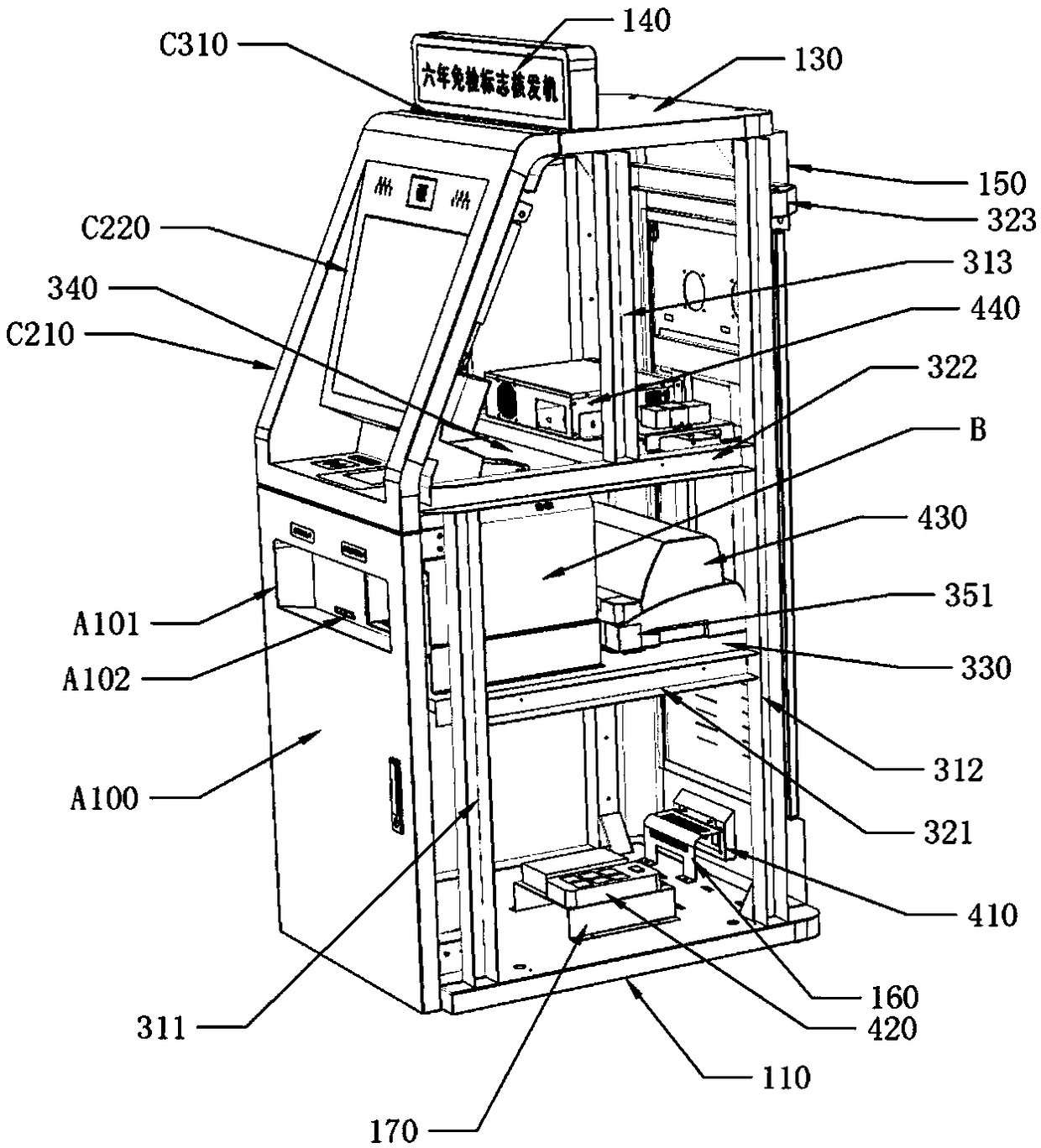

[0064] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

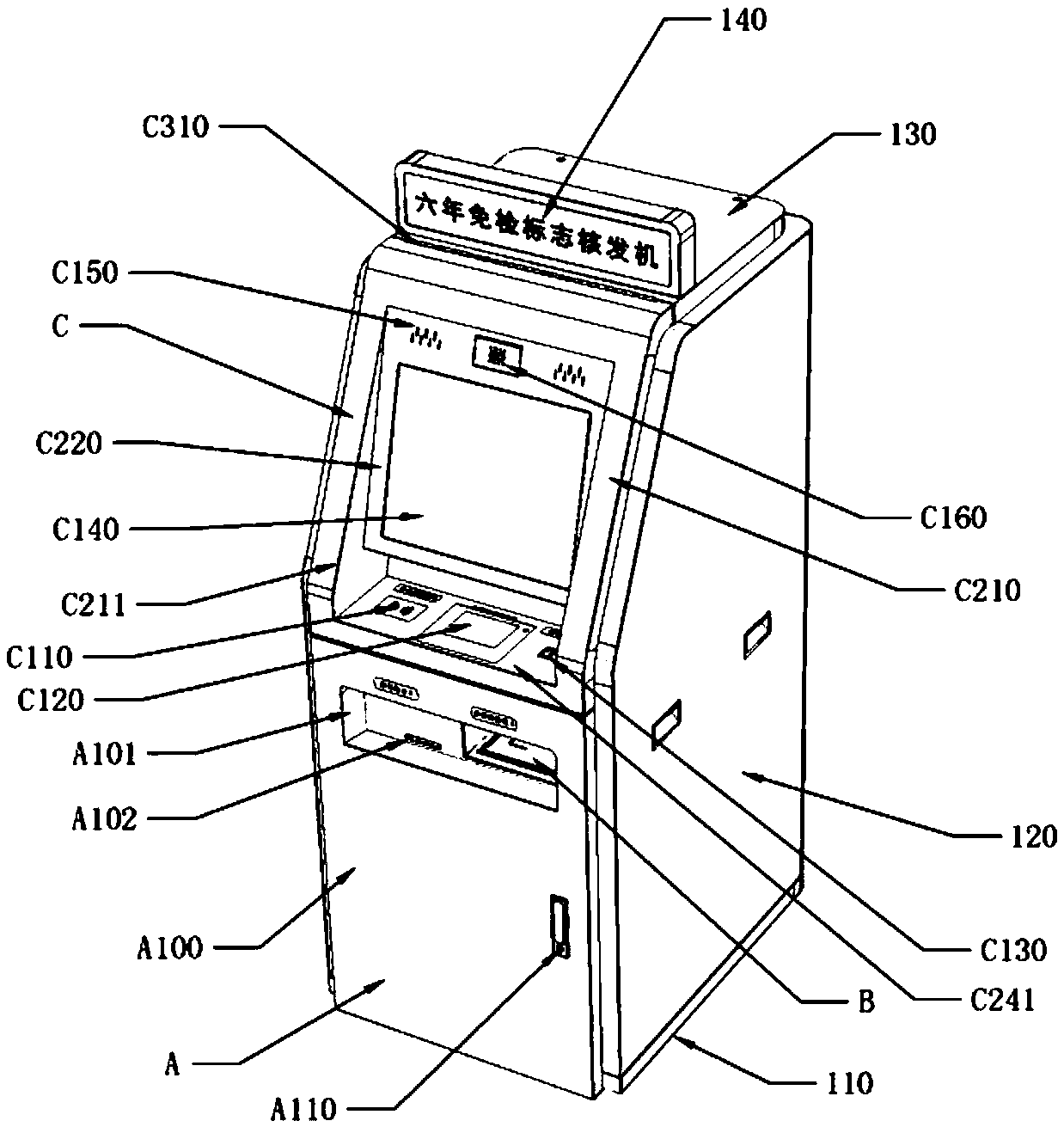

[0065] see Figure 1-Figure 6 , a vehicle inspection-free label self-dispensing machine, including a frame, a panel assembly C, a label module E, and a high-speed camera assembly B, and a front door panel assembly A and a rear door panel assembly D are installed on the frame. The frame includes a base plate 110, two side plates 120 are installed on the base plate 100, a top plate 130 is installed on the top of the side plate 120, and an identification plate 140 is installed on the top plate 130;

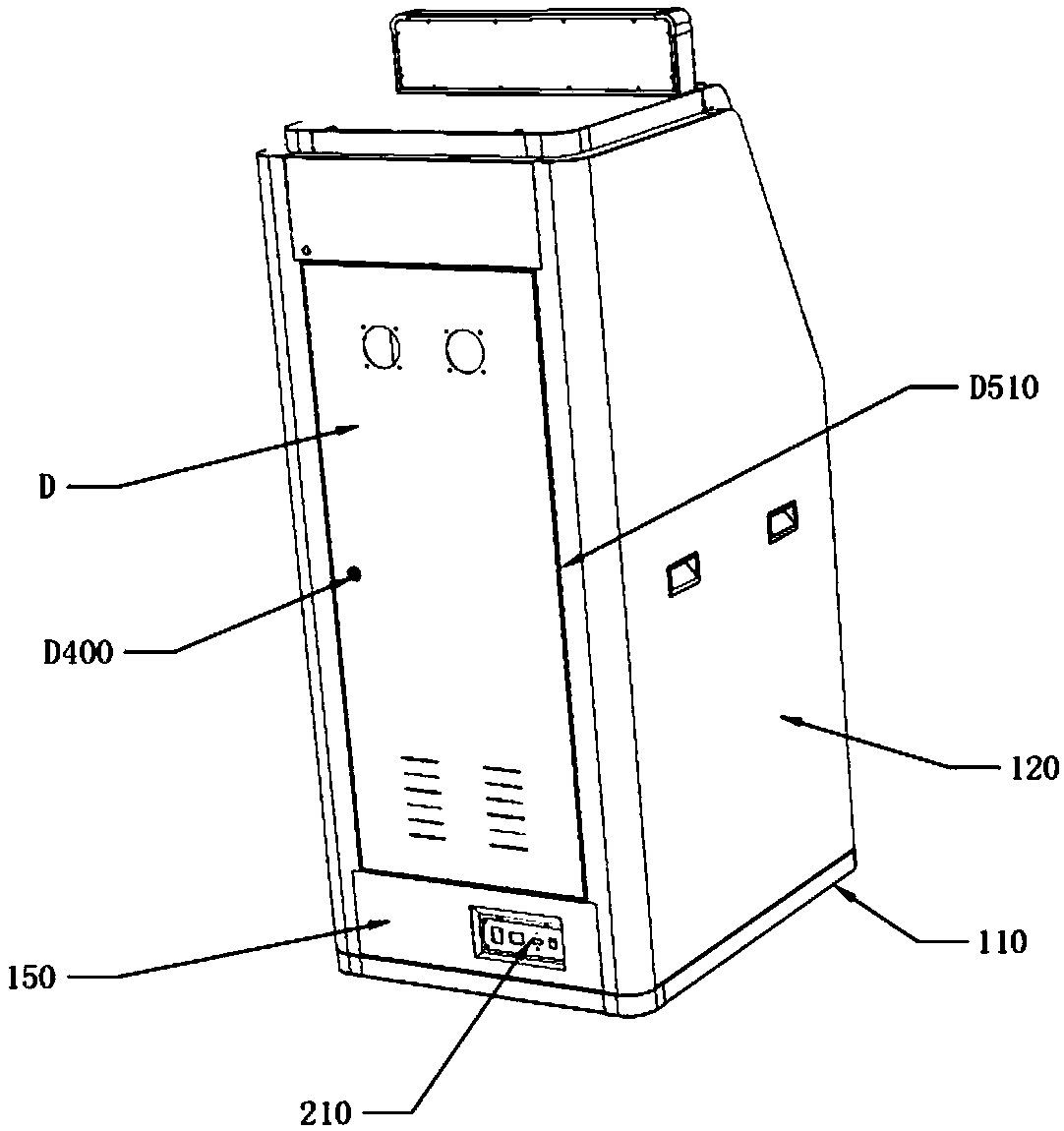

[0066] The side panels 120 are installed on both sides of the frame parallel to each other, the front door panel assembly A and the rear door panel assembly D are respectively installed on the other two parallel sides of the frame, and the rear door panel assembly D is installed on the back plate 150;

[0067] The two sides of the back plate 150 are assembled and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com