Plastic bag folding press

A technology of plastic bags and folding machines, applied in the direction of folding thin materials, thin material processing, container manufacturing machinery, etc., can solve the problems of high labor intensity and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

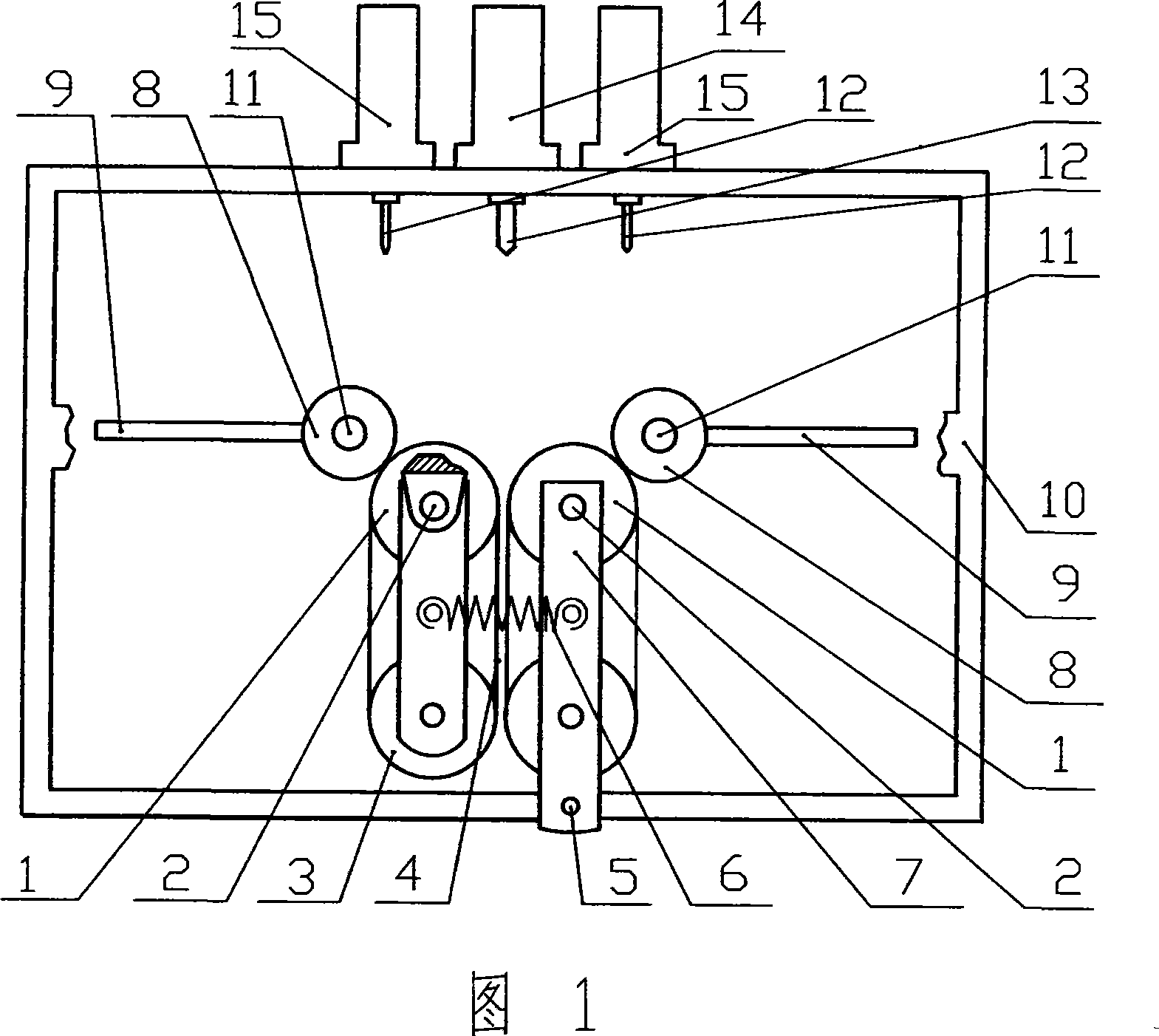

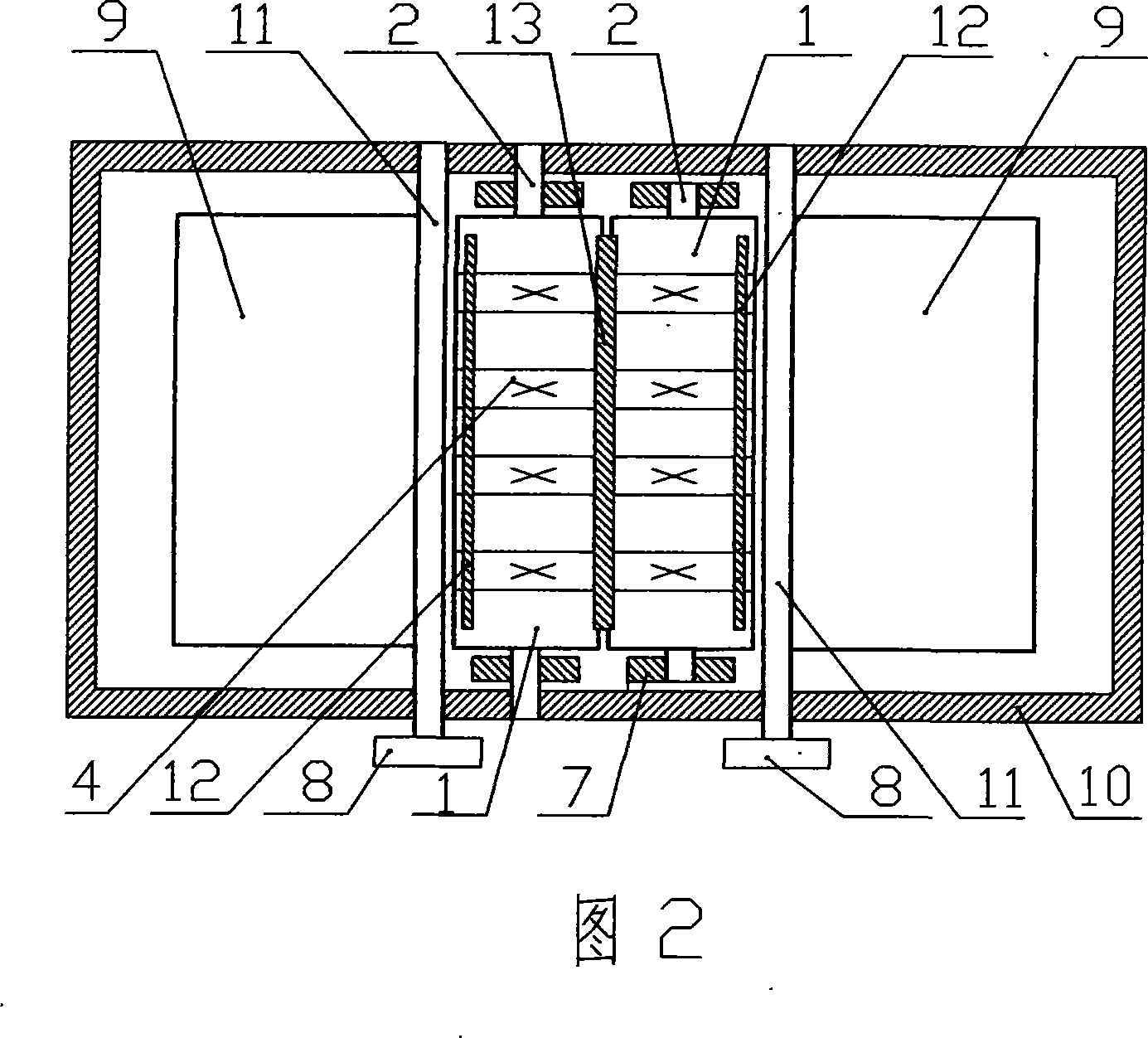

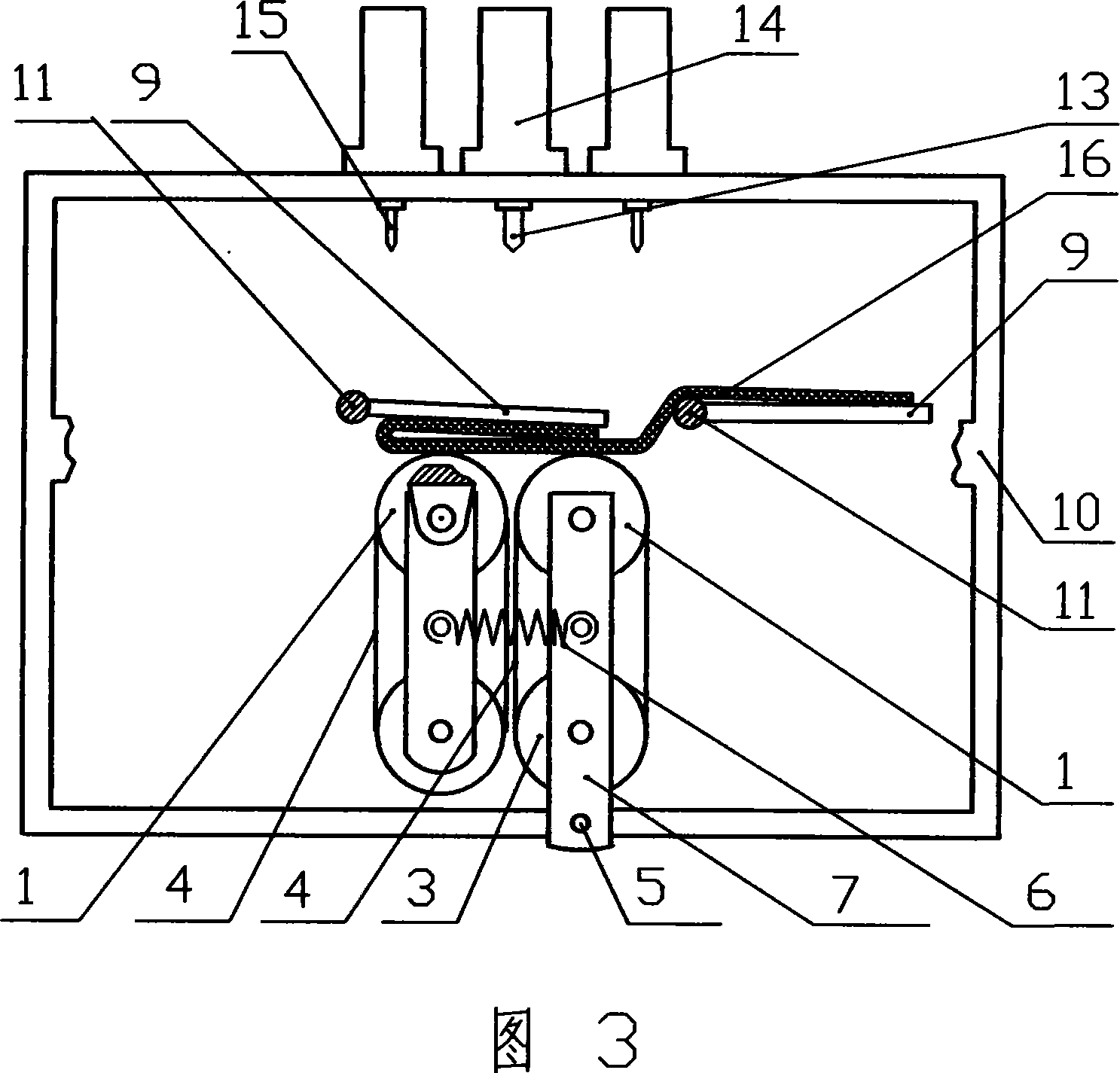

[0012] As shown in accompanying drawing 1, accompanying drawing 2, accompanying drawing 3, accompanying drawing 4, accompanying drawing 5, accompanying drawing 6, plastic bag folding machine comprises frame 10, two crimping rollers 1 are arranged in parallel on the frame, crimping A bracket 7 is arranged on the journal 2 at both ends of the roller, the lower end of the bracket is connected with the lower part of the frame with a pin shaft 5, the bracket 7 can swing around the pin shaft 5, and the belt pulley 3 is installed on the bottom of the bracket, and the belt pulley 3 and the crimping roller 1 Multiple belts 4 are installed, springs 6 are installed between the two brackets, and the brackets 7 are pulled by the springs 6 to make the two crimping rollers 1 approach in parallel; an insertion folding plate 13 is installed above the two creasing rollers, and the upper end of the insertion folding plate is connected to the cylinder 14. When the cylinder is inflated, it can driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com