Automatically-moving three-dimensional seedbed system with adjustable light transmittance

A technology of automatic movement and light transmittance, applied in energy-saving measures, agricultural machinery and equipment, horticulture, etc., can solve the problems of low degree of intelligent control, increasing the light rate of seedbeds, backward seedling technology, etc., and achieve good system flexibility , low operating costs and management costs, and the effect of saving manpower, material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

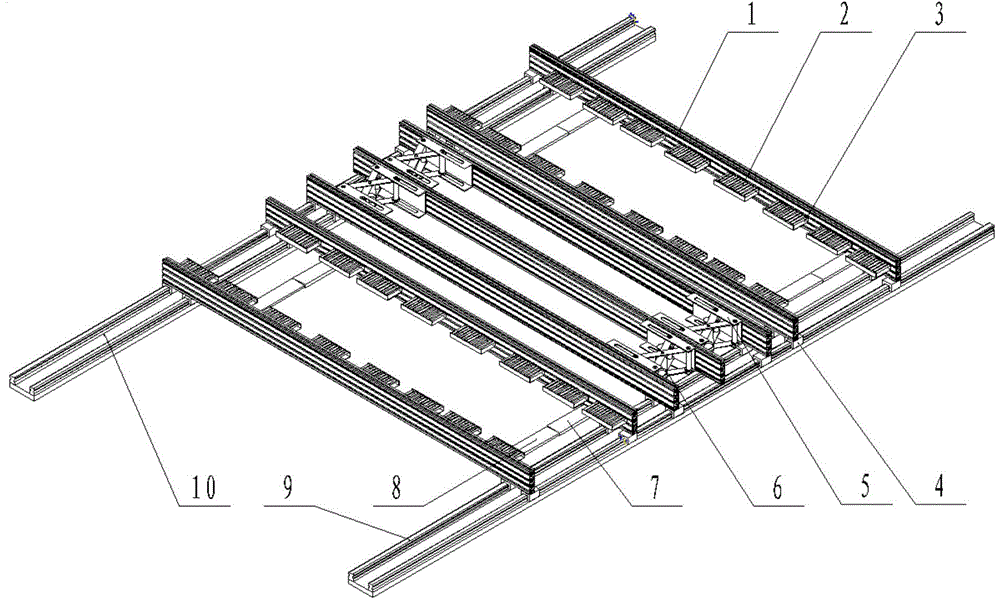

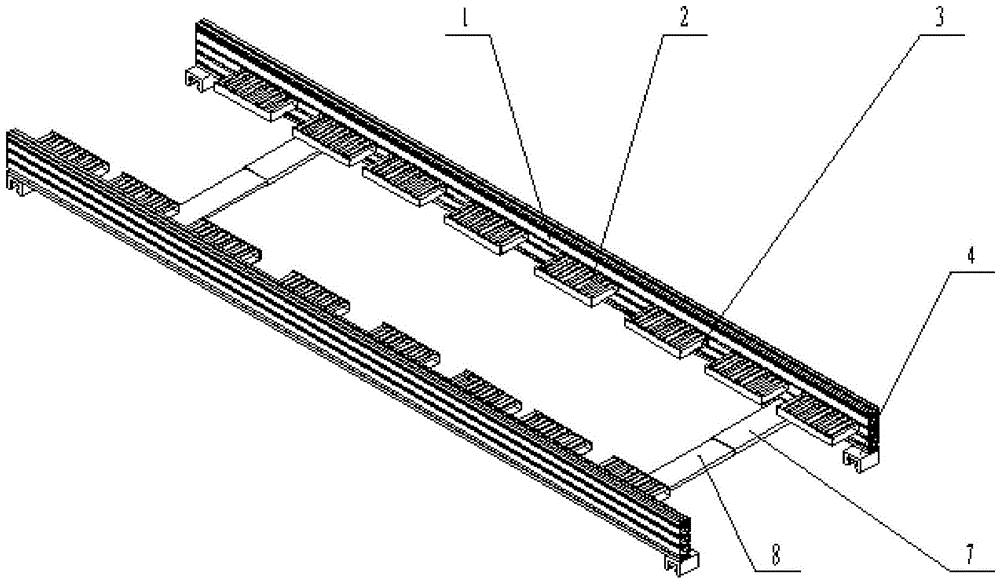

[0047] An automatic mobile three-dimensional seedbed system with adjustable light transmittance, such as figure 1 , figure 2 , Figure 10 As shown, the three-dimensional seedbed system includes a three-dimensional frame body, a linear guide rail 9, a seedbed conveying unit, a seedbed spacer unit, a single seedbed 17 and a sensor positioning device, and the linear guide rail 9 is layered on the three-dimensional frame body through a support plate 10.

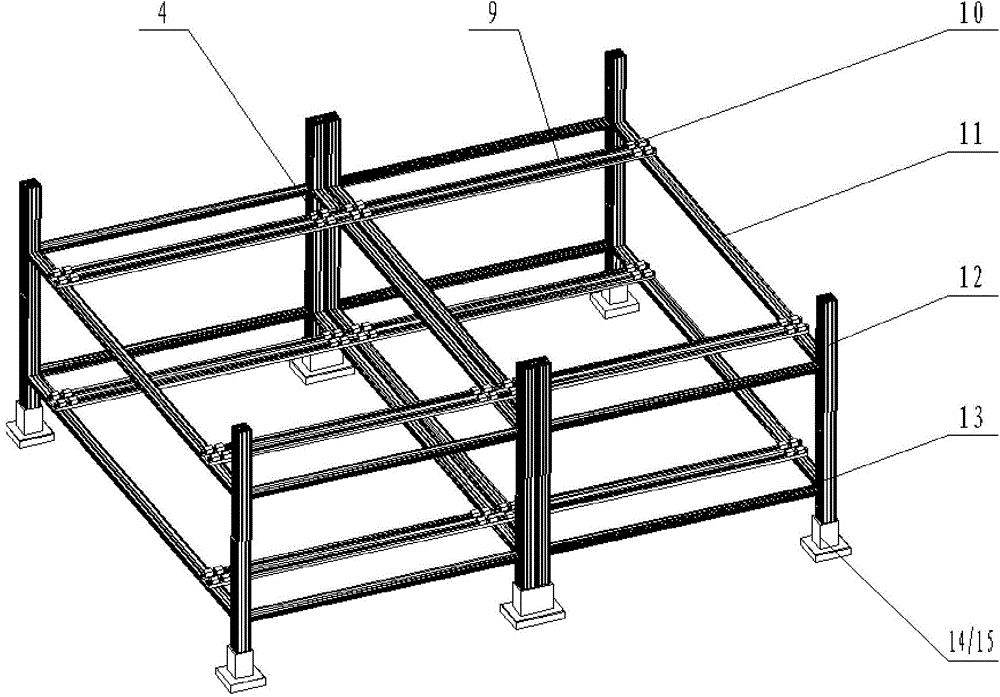

[0048] three-dimensional frame figure 2 As shown, the three-dimensional frame body is formed by a support rod 12 vertically arranged, and a vertical rod 11 and a cross bar 13 arranged horizontally on the support rod 12 are combined to form, and the lower side of the support rod 12 is provided with a cylinder support seat 14, and the cylinder support seat 14 is fixed on the ground, is provided with cylinder 15 in the cylinder support seat 14, and cylinder 15 drives support rod 12 to move up and down, and longitudinal bar 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com