Dust recycling device for high-tower granulation of compound fertilizer

A technology of dust recovery and high-tower granulation, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to absorb dust, easy sedimentation, and large loss of daily output, and achieves reasonable and ingenious design structure. The effect of improved recovery rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment the present invention is described in further detail.

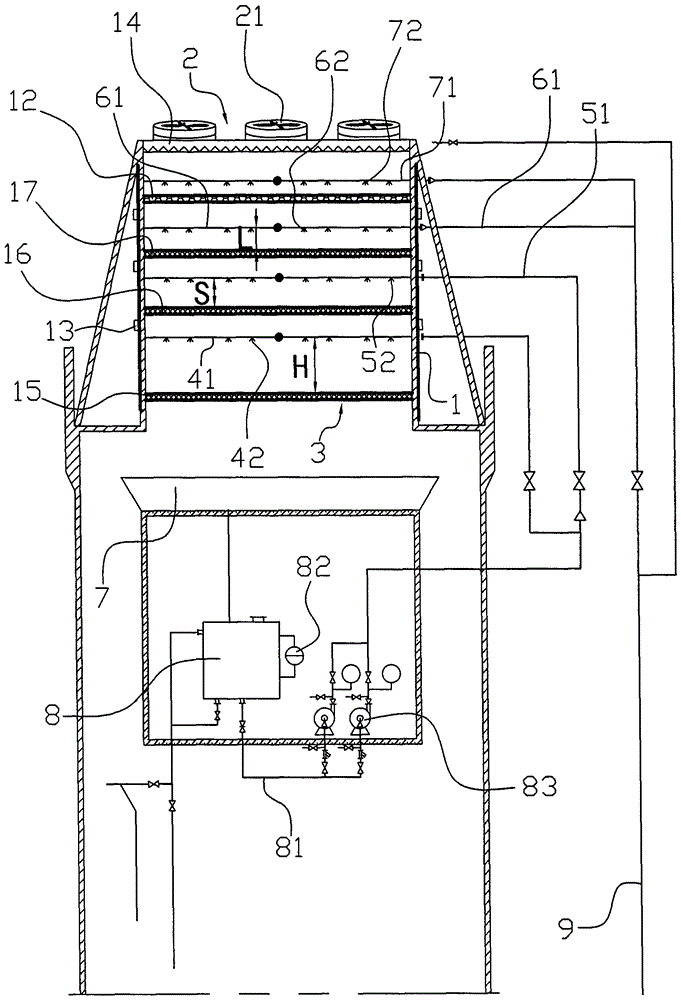

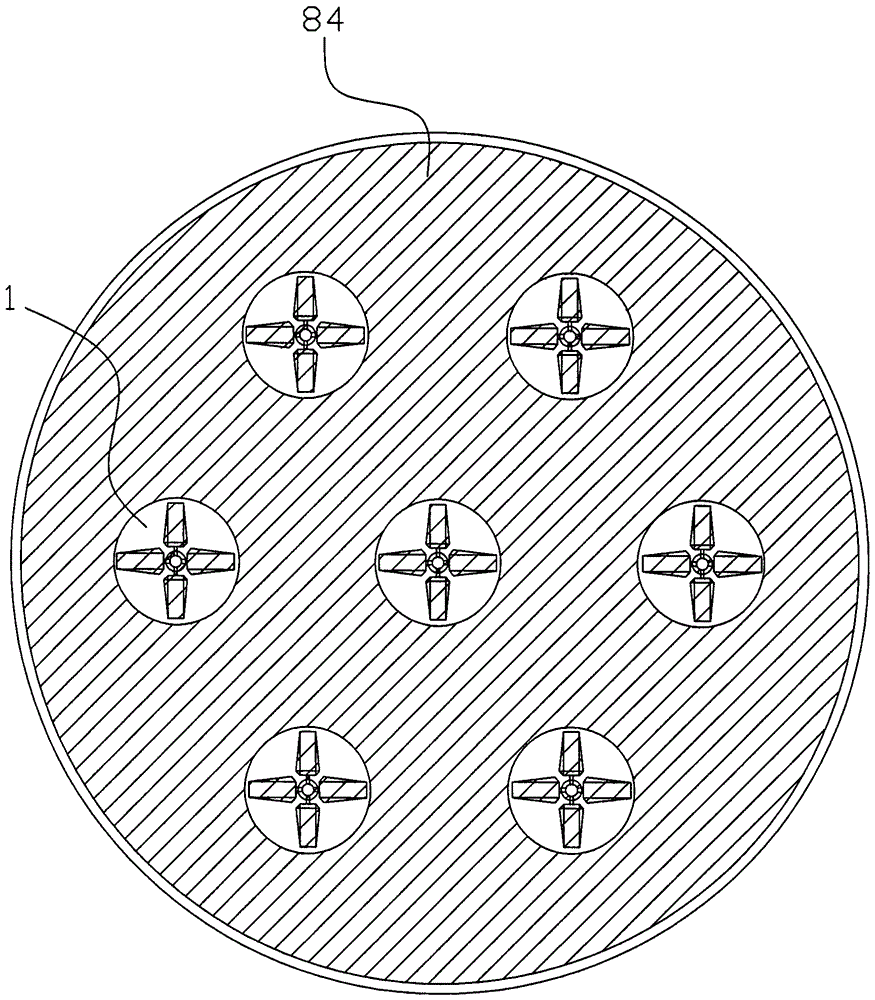

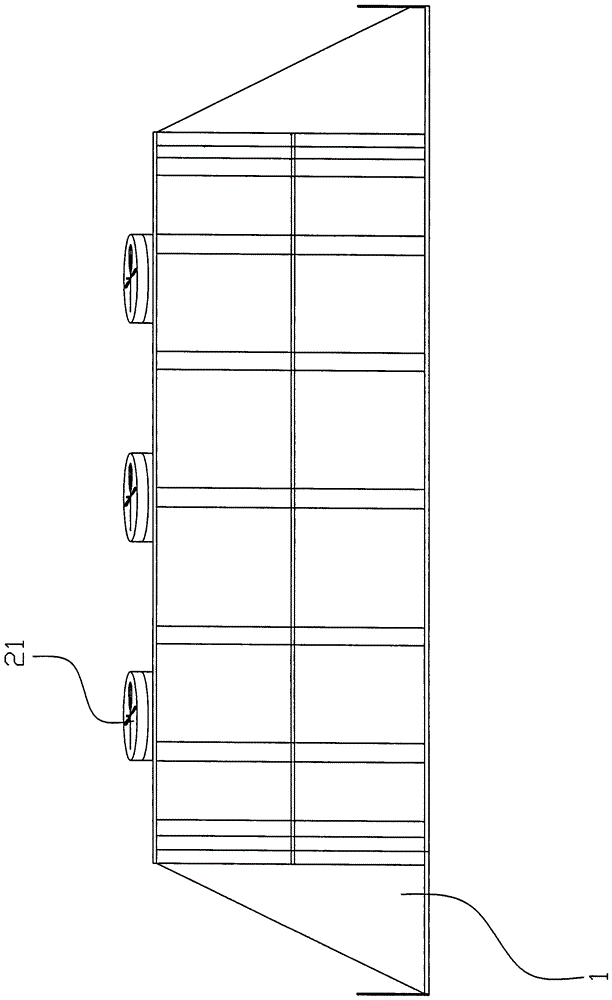

[0034] Such as Figure 1 to Figure 3As shown, the dust recovery device for compound fertilizer high-tower granulation in this embodiment includes a housing 1 and a collection tank 7. An air outlet 2 is provided at the upper end of the housing 1, and an air outlet 2 is provided in the air outlet 2. There is an exhaust fan 21, the lower end of the housing 1 is provided with an air inlet 3, and the housing 1 is provided with a first spray device, a second spray device, and a third spray device at intervals from bottom to top, The air inlet 3 at the lower end of the housing 1 is provided with a first packing layer 15 capable of filtering dust, and a second packing layer 16 is provided between the first spraying device and the second spraying device. A third packing layer 17 is provided between the second spraying device and the third spraying device, a fourth spraying device is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com