Method for optimizing low pneumatic noise of high-speed train head section longitudinal symmetry plane line

A high-speed train, aerodynamic noise technology, applied in the direction of image data processing, special data processing applications, instruments, etc., can solve problems that are not clear and stay in the stage of qualitative understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

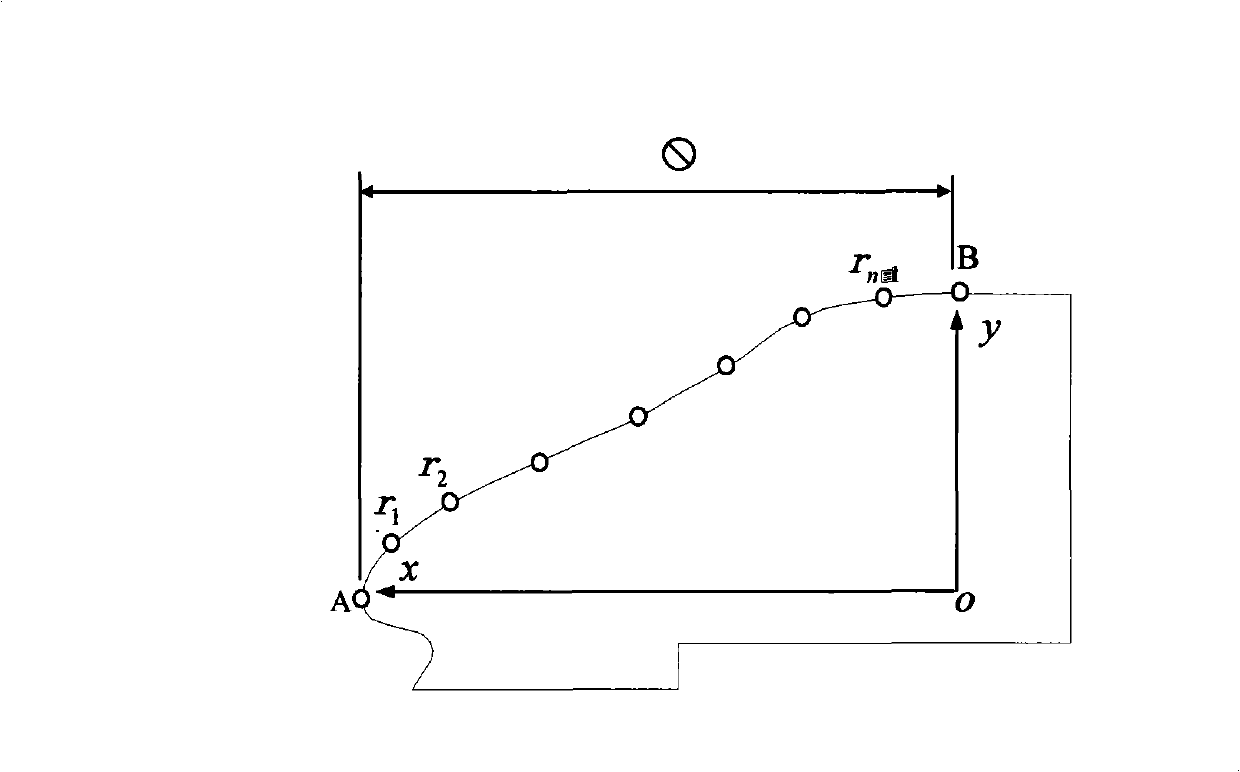

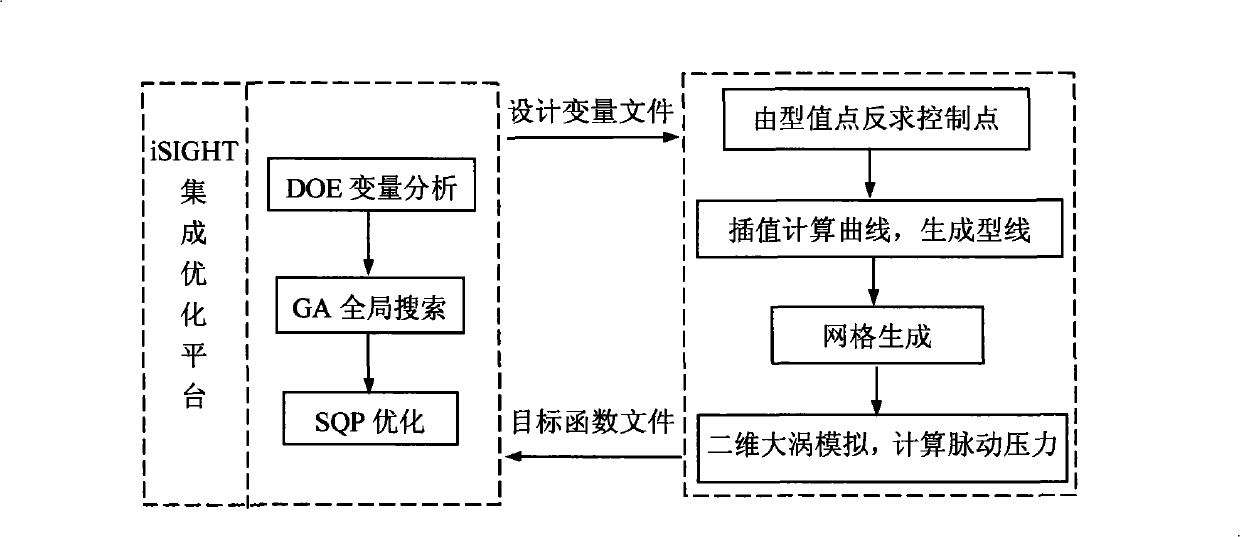

[0027] Such as Figure 1 to Figure 2 As shown, the low aerodynamic noise optimization method for the longitudinal symmetry profile of the high-speed train head includes the following three steps:

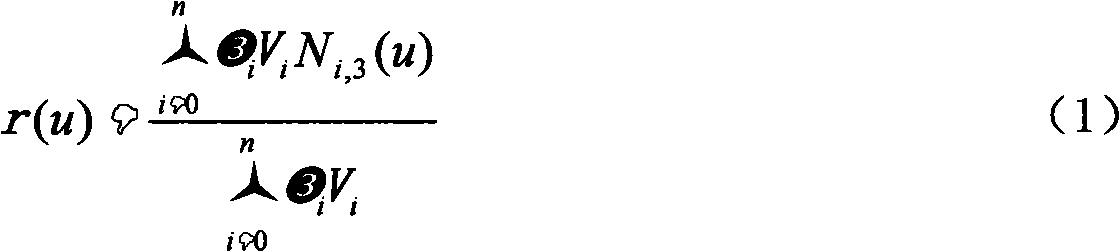

[0028] Step A: Use the cubic NURBS (Non-Uniform Rational B-Spline) curve parametric modeling method to obtain the parametric modeling of the longitudinal symmetry surface profile of the train head.

[0029] Such as figure 1 As shown, according to the length and height of the train head, the longitudinal symmetry profile can be determined The first and end points A and B are the guarantee line The part between the two ends of A and B transitions smoothly to the other parts, the tangent vector of end A is vertically upward, and the tangent vector of end B is horizontally to the right, and its profile line The position and number of upper intermediate point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com