IBC (Intermediate Bulk Container) lining bag, intermediate bulk container with lining bag and use method of lining bag

A lining and bag body technology, which is applied in the field of IBC liner bags, can solve the problems of time-consuming and labor-intensive installation of chemical barrel liner bags, and achieve the effects of saving procedures, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The specific implementation of this embodiment is as follows:

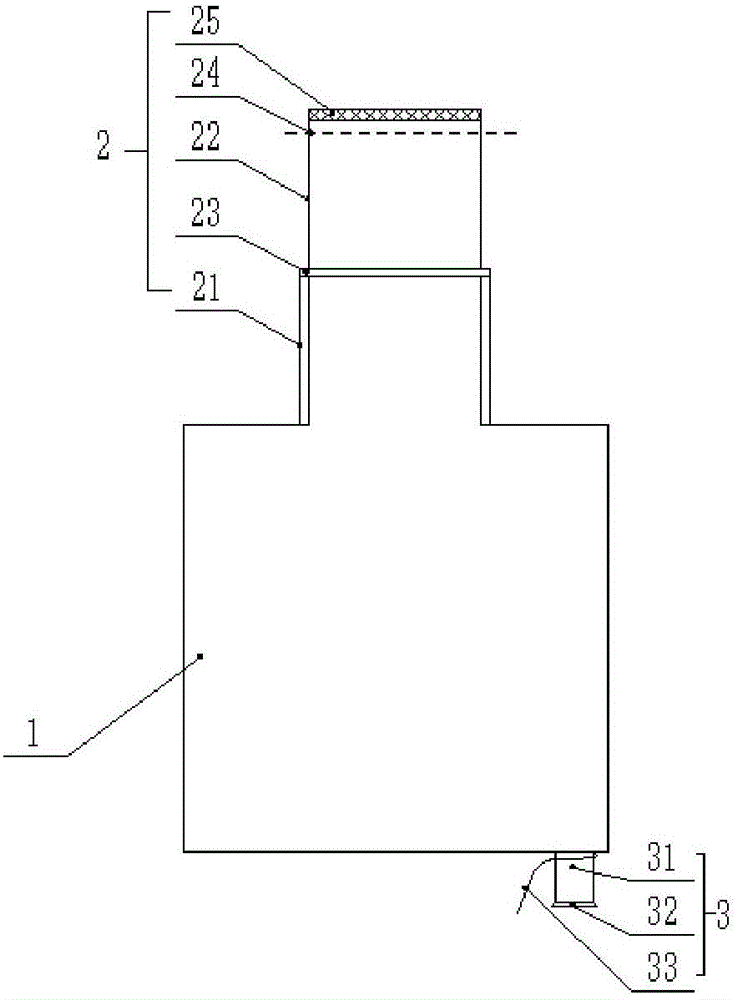

[0045] Such as figure 1 As shown, the IBC tote liner bag provided in this embodiment includes a bag body 1, an opening is arranged on the top of the bag body 1, the opening is sealed and connected with a feeding part 2, and the bottom of the bag body 1 is sealed and connected with a discharge part 3. The feeding part 2 includes an outer layer protective film 22 and an inner layer material storage film 21 from the outside to the inside, the top surface of the outer layer protective film 22 is wrapped with a first sealing ring 23, and the top of the inner layer material storage film 21 is directly Sealed.

[0046] It should be noted that the IBC ton barrel of the present invention is an essential tool for modern storage and transportation of liquid products. The container barrel is composed of an inner container and a metal frame. The inner container is blow-molded with high-molecular weight and high-density...

Embodiment 2

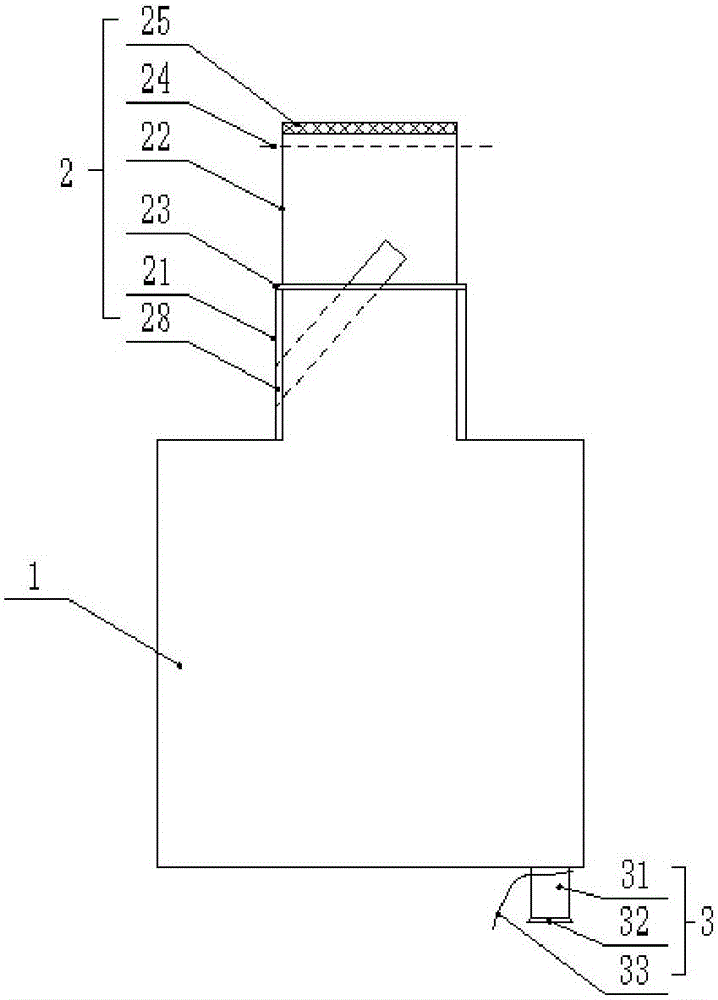

[0062] Such as image 3 As shown, the IBC tote liner bag provided in this embodiment not only includes the structure of the IBC tote liner bag in the first embodiment above, but also includes the following technical features:

[0063] Specifically, the lower part of the side wall of the outer protective film 22 is communicated with a suction pipe 28 , and the suction pipe 28 is arranged between the inner storage film 21 and the outer protective film 22 .

[0064] Specifically, the inner storage film 21 is connected to the bottom surface of the outer protective film 22 .

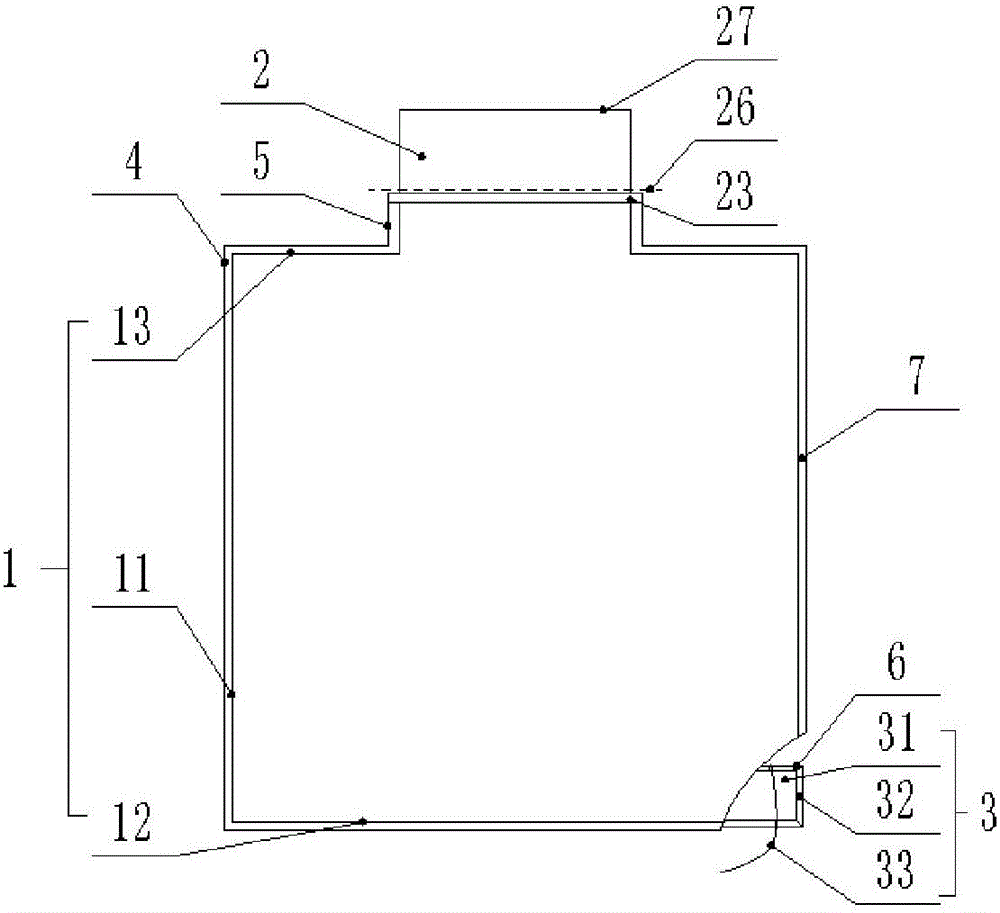

[0065] Specifically, the bag body 1 includes a bag side wall 11, a bag bottom wall 12, and a bag top wall 13, wherein the bag side wall 11, the bag bottom wall 12, and the bag top wall 13 are respectively closely attached to the inner wall of the tote or left Bucket bag clearance 7.

[0066] Adopt the IBC ton barrel liner bag of this embodiment, on the basis of the liner bag of embodiment one, increase the ...

Embodiment 3

[0071] A method for using a liner bag provided in this embodiment includes the IBC tote liner bag of the above-mentioned embodiment 1 or embodiment 2 and a tote with a liner bag, and the specific steps are as follows:

[0072] In step a, the liner bag of the IBC tote is loaded through the upper feed port 27 of the IBC tote, wherein the second sealing ring 32 of the discharge part 3 is pulled out of the discharge port 31 of the IBC tote by a traction rope, and then Cooperate with the discharge valve 6 to install;

[0073] Step b, open the discharge valve 6, inflate the liner bag through the discharge part 3, fill the liner bag with air, so that the liner bag fits the inner wall of the IBC tonnage, and then close the discharge valve 6;

[0074] Step c, pull out the liner bag feeding part 2 from the upper feeding port 27 of the IBC tote;

[0075] Step d, if the lamination effect is found to be lacking, the air pump 28 can be used to communicate with the air pump, and the air pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com