Preparation method of composite drug-loaded fiber based on microfluidics spinning

A fiber and drug-carrying technology, applied in fiber processing, pharmaceutical formulations, fiber chemical characteristics, etc., can solve the problems of physical injury, destruction of drug molecule activity, destruction of drug activity, etc., to inhibit crystallization, improve drug loading, Improves the effect of sustained release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

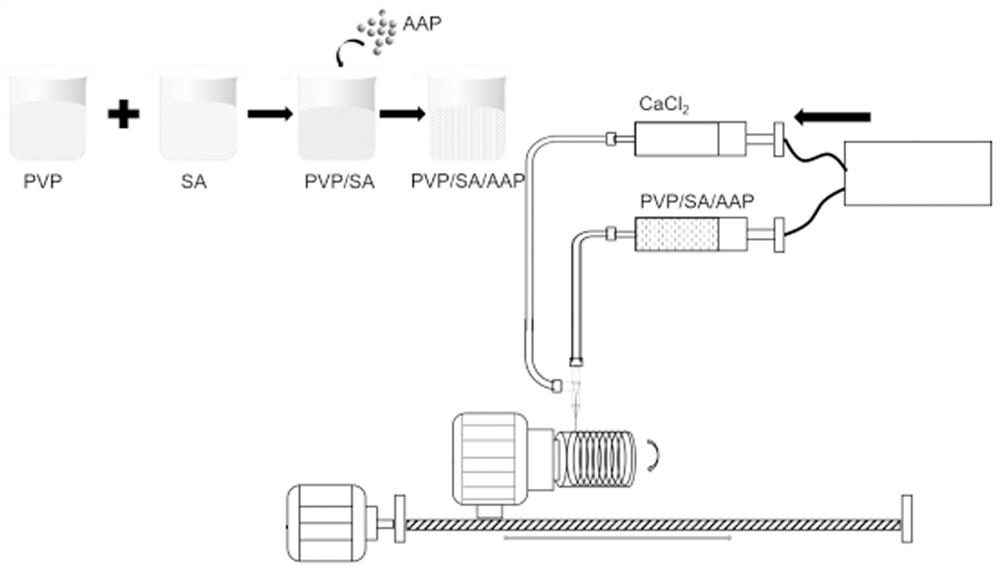

[0038] like figure 1 As shown in FIG. 1 , a flow chart of preparation of a composite drug-loaded fiber based on microflow spinning provided by the present invention is shown. The preparation method based on microflow spinning composite drug-loaded fiber comprises the following steps:

[0039]A1. Take polyvinylpyrrolidone and sodium alginate, add water respectively, stir and heat to obtain polyvinylpyrrolidone solution and sodium alginate solution;

[0040] A2, mixing polyvinylpyrrolidone solution and sodium alginate solution, then adding acetaminophen to form a mixed spinning solution;

[0041] A3. Preparation of continuous composite drug-loaded fibers by means of microfluidic spinning. Embodiment one

Embodiment 1

[0042] Since the microfluidic spinning is carried out at normal temperature and pressure, the spinning liquid is not subjected to other external forces except the thrust of the syringe pump during the entire continuous spinning process, so in order to ensure the normal progress of the spinning process, the solution The concentration is very important for spinning. In order to ensure that the fiber only swells but does not dissolve during the drug release process, it is also important to find the appropriate concentration of sodium alginate and calcium chloride by using ion cross-linking to quickly solidify the fiber. Therefore, this example is to verify the effect of different spinning solution concentrations on the formation of PVP / SA / AAP composite drug-loaded fibers.

[0043] PVP solution and SA solution have a certain viscosity, and as the concentration increases, the solution viscosity will also increase. Since the flow channel of the spinning solution is relatively narro...

Embodiment 2

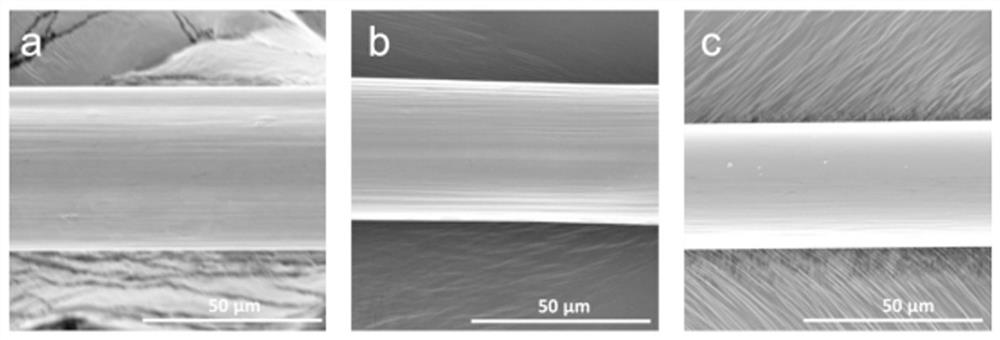

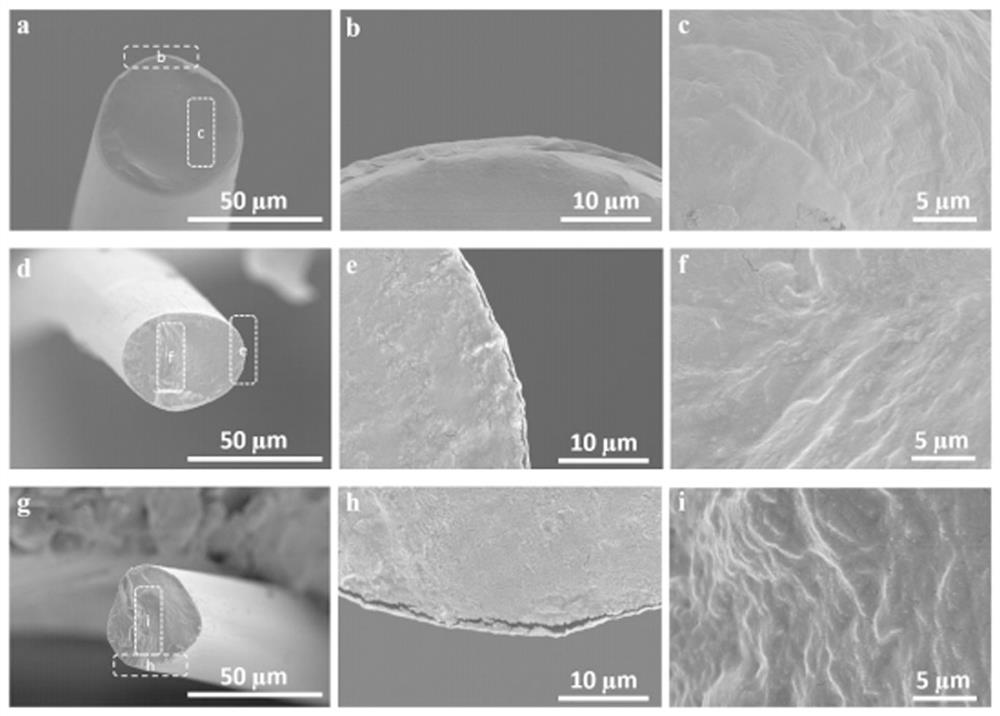

[0057] This example explores the effect of different AAP mass fractions on the morphology of composite fibers. SEM images of drug-loaded PVP / SA / AAP composite fibers with different AAP mass fractions. Fix the conductive adhesive on the electron microscope stage, then take several PVP / SA / AAP composite fibers prepared above and stick them on the conductive adhesive, spray gold for 90s, and use R-8100 cold-field scanning electron microscope to observe the surface morphology of the fibers. The test condition is a voltage of 3kV and a voltage of 10mA. The composite fiber was brittle broken with liquid nitrogen, and the cross-sectional morphology of the fiber was observed using the same test method and test conditions.

[0058] like Figure 4 shown, where Figure 4 a, 4b, 4c and 4d are shown as SEM images of PVP / SA / AAP composite fibers with AAP mass fractions of 0wt%, 10wt%, 20wt% and 30wt%, respectively.

[0059] from Figure 4 Among them, the surfaces of PVP / SA / AAP composite f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com