Preparation method of conductive drug-loaded composite fiber

A composite fiber and drug-loading technology, which is applied in the manufacture of conductive/antistatic filaments, fiber treatment, and pharmaceutical formulations. It can solve problems such as physical damage and damage to drug molecular activity, achieve good compatibility, and improve drug loading. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

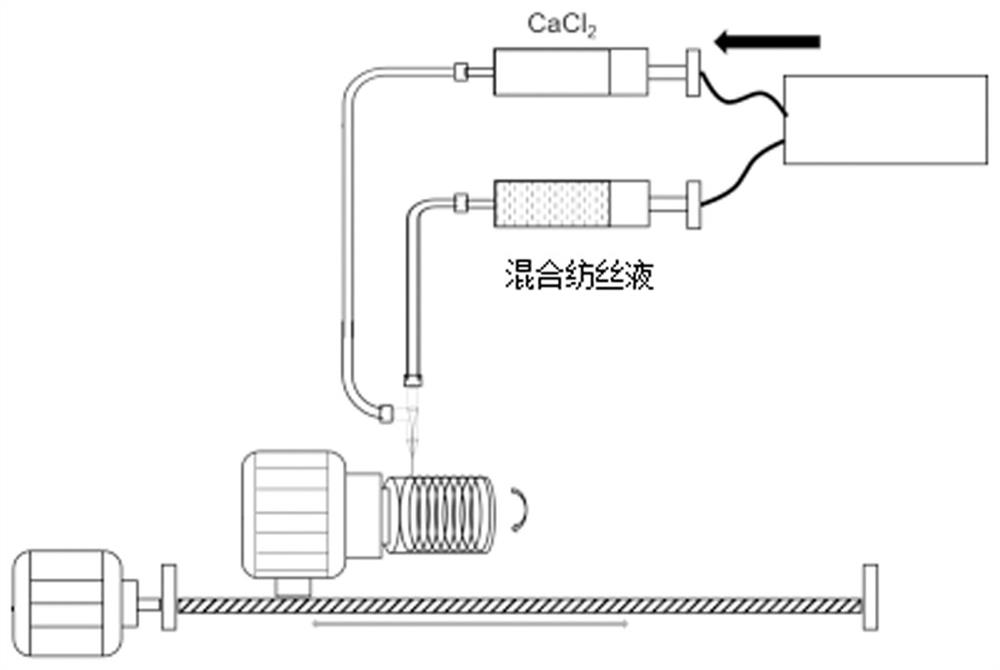

[0043] like figure 1 As shown, a flow chart of the preparation of a microfluidic-based composite drug-loaded fiber provided by the present invention is shown. The preparation method of the microfluidic composite drug-loaded fiber comprises the following steps:

[0044]S1, get PVP and SA, stir and heat after adding water respectively, obtain PVP solution and SA solution;

[0045] S2. Mix the PVP solution and the SA solution, and then add APP to form a PVP / SA / AAP solution;

[0046] S3, adding PEDOT:PSS aqueous solution to the PVP / SA / AAP solution to form a PVP / SA / AAP / PEDOT:PSS mixed spinning solution;

[0047] S4. Preparation of continuous conductive drug-loaded composite fibers by microfluidic spinning, namely PSAP composite fibers

Embodiment 1

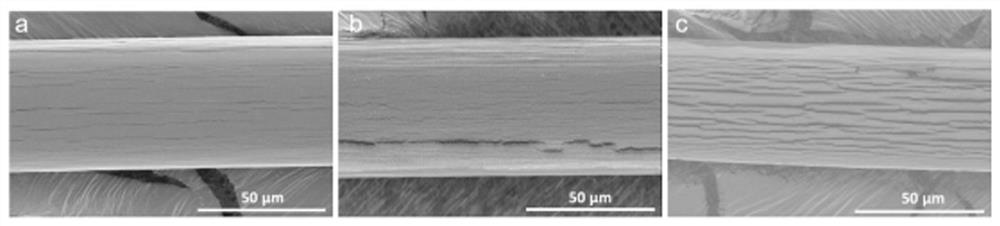

[0049] In this example, the PSA composite drug-loaded fiber is taken as an example to verify the influence of different spinning solution concentrations on the forming of PSA composite drug-loaded fiber, and then to verify the morphology characterization of PEDOT:PEDOT:PSS at different concentrations on the forming of PSAP composite fiber .

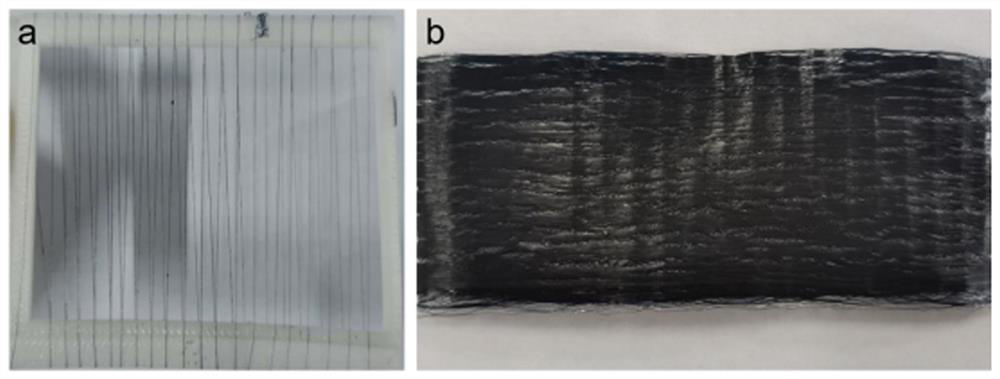

[0050] Among them, the difference between the preparation method of the PSA composite drug-loaded fiber and the above-mentioned PSAP composite fiber is whether PEDOT:PSS is added to the mixed spinning solution. First, through the verification of the solution concentration, ratio and microfluidic spinning process related parameters in the PSA composite drug-loaded fiber, the concentration of the PVP / SA / AAP mixed spinning solution that can continuously prepare the fiber is found. The PVP / SA / AAP / PEDOT:PSS mixed spinning solution with a mass fraction of 30wt%, 40wt% and 50wt% of the PVP / SA / AAP solution was used for morphology characterization...

Embodiment 2

[0064] In the above preparation method, the microfluidic spinning process parameters have a certain influence on the fiber forming. Therefore, this example aims to explore the influence of microfluidic spinning process parameters on fiber formation.

[0065] The microfluidic spinning machine is mainly composed of a microfluidic syringe pump and a fiber receiving platform. The first part of the microfluidic syringe pump is used to control the output speed and output of the spinning solution, mainly including: dual-channel syringe pump, syringe, Teflon tube and coaxial needle. The second part of the fiber receiving platform is used to receive fibers, and mainly includes a drum receiver, a rotating motor, a circular stepping translation platform, a heater and a control panel. The dual-channel syringe pump can independently control the two syringes and set different advancing speeds. The components of the microfluidic spinning device are connected by polytetrafluoroethylene tubes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com