Method for preparing double-wall-layer fresh ginger volatile oil microcapsules

A technology of volatile oil and microcapsules, which is applied in the field of preparation of double-walled ginger volatile oil microcapsules, can solve problems such as poor stability, achieve good stability, simple preparation process, and good embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

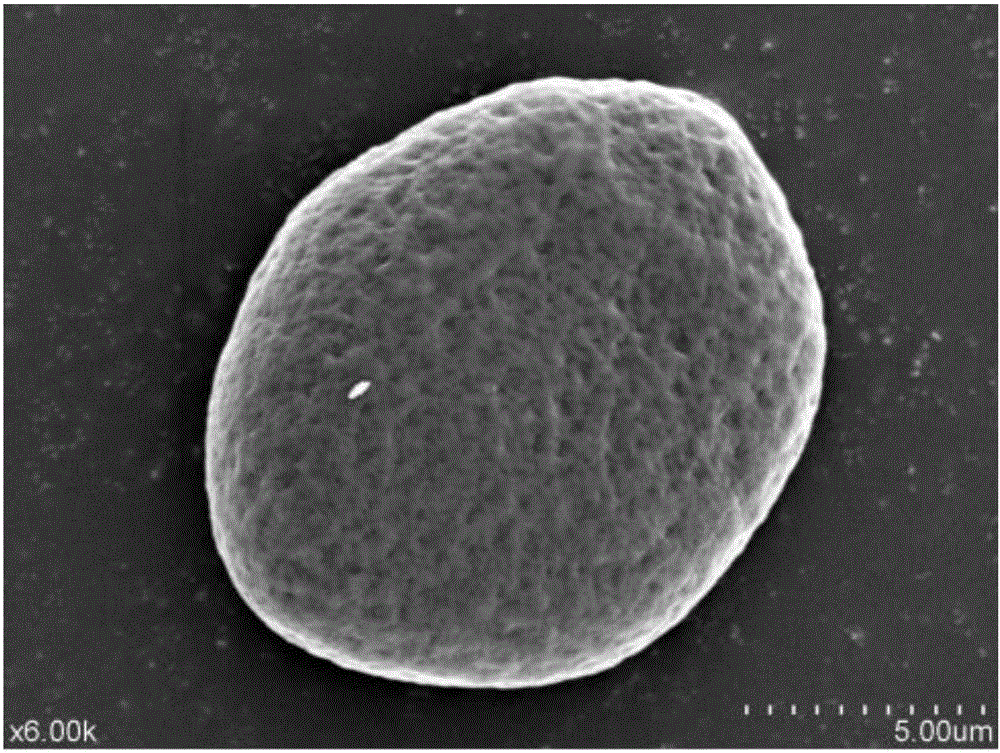

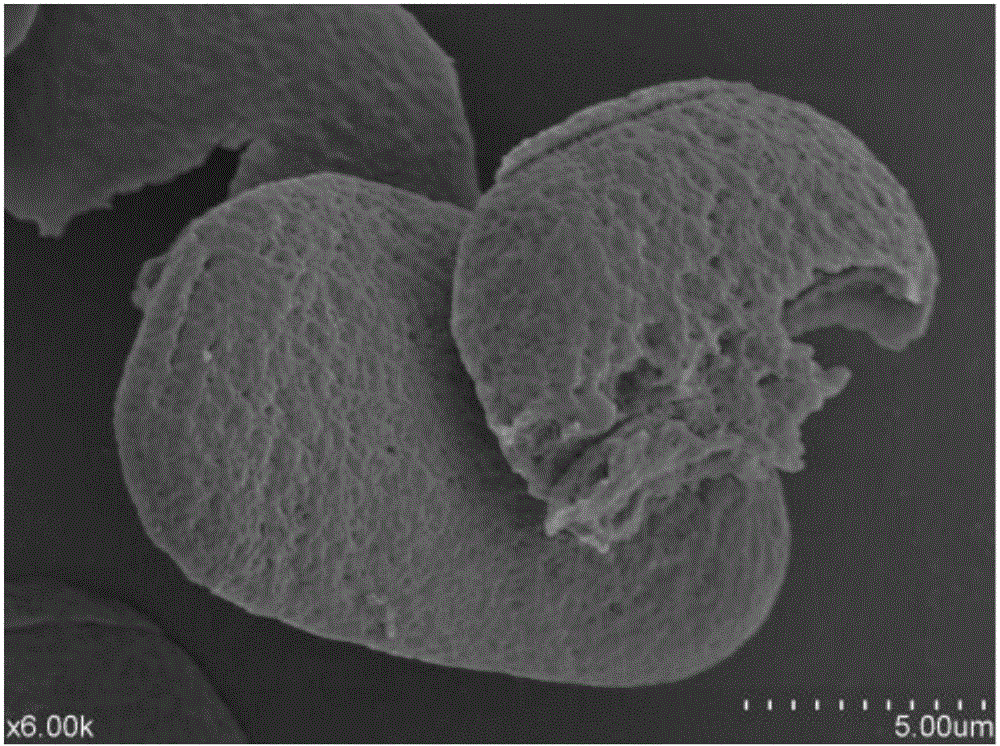

Image

Examples

Embodiment 1

[0029] A preparation method of double-walled ginger volatile oil microcapsules, the steps are:

[0030] (1) taking by mass ratio 1:2-8, taking the ginger oil that the core material is supercritical extraction, and the inner layer wall material is gelatin, homogeneous at normal temperature, and preparing the suspension;

[0031] (2) Dissolve 5-15 parts of octenyl succinic yam starch ester of the outer wall material in 60-90 parts of hot water, cool to room temperature, add 3-10 parts of lecithin as an emulsifier, and adjust the pH to 2-6;

[0032] (3) Disperse the suspension prepared in step (1) into the solution in step (2), disperse at a high speed of 15000r / min for 2min, homogenize under high pressure of 30-100MPa, repeat 3 times;

[0033] (4) freeze-drying the suspension to obtain double-walled ginger volatile oil microcapsules.

[0034] The composition of the double-walled ginger volatile oil microcapsules is: yam starch octenyl succinate: gelatin: lecithin: ginger volati...

Embodiment 2

[0039] Different from Example 1 is the preparation method of octenyl succinic acid yam starch

[0040] (1) Fresh yams are washed, peeled and sliced, dried with hot air at 50°C, crushed dried yam slices, passed through a 100-mesh sieve, and mixed with sodium hydroxide at pH=9 according to a solid-liquid ratio of 1:8 Soak in the solution for 2 hours, wash with 90% ethanol for several times, and dry the precipitate to obtain yam starch.

[0041] (2) A certain amount of yam starch is prepared into starch milk of a certain concentration with distilled water, stirred quickly to make a homogenate, adjust the pH value of the starch milk with 2% sodium hydroxide, and keep the whole reaction process at this pH value, add octenyl succinic anhydride at a certain temperature (the amount of anhydride added is 3% of the dry base of starch, the anhydride is diluted with absolute ethanol before adding, and the anhydride is slowly added to the starch milk within 2 hours), and react for a certai...

Embodiment 3

[0043] The difference from Example 1 is that the inner wall material is monoglyceride, and the outer wall material is sodium carboxymethyl cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com