Combustible gas detector and calibration method thereof

A gas detector and gas sensor technology, applied in the direction of material resistance, can solve the problems of inconvenient adjustment, unsuitable for various use requirements and calibration, and achieve diversified signal output methods, meet market demand, and strong scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

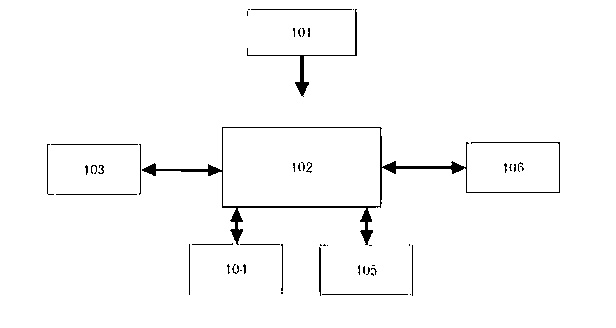

[0042] The specific embodiment of the present invention will be further described in detail below with reference to the accompanying drawings, taking the combustible gas sensor NAP-55A as an example.

[0043] The external 24V power supply is used as the power supply voltage of the whole system to input the power management unit 101. The power management unit 101 converts the 24V voltage to 5V voltage through the voltage regulator chip to supply power to the 5V electric circuit. V supplies power to the 2.5V electrical system circuit. In the present invention, what needs 5V power supply is the main control chip unit 102, the output alarm unit 104, the communication circuit unit 106,

[0044]The sensor and interface circuit unit 103, the communication circuit unit 106; the sensor and interface circuit unit 103 needing 2.5V power supply; the output alarm unit 104, and the V / I conversion circuit unit 105 are powered by 24V voltage. The combustible gas detector is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com