Coal mine paste filler online monitoring system based on optical fiber grating sensing

A fiber grating and paste filling technology is applied in the measurement, measuring device, and optical device by measuring the changing force of the optical properties of the material when it is stressed. High pressure or water, force and deformation manual measurement, etc., to achieve the effect of guiding on-site production and scientific research work, on-site safety, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

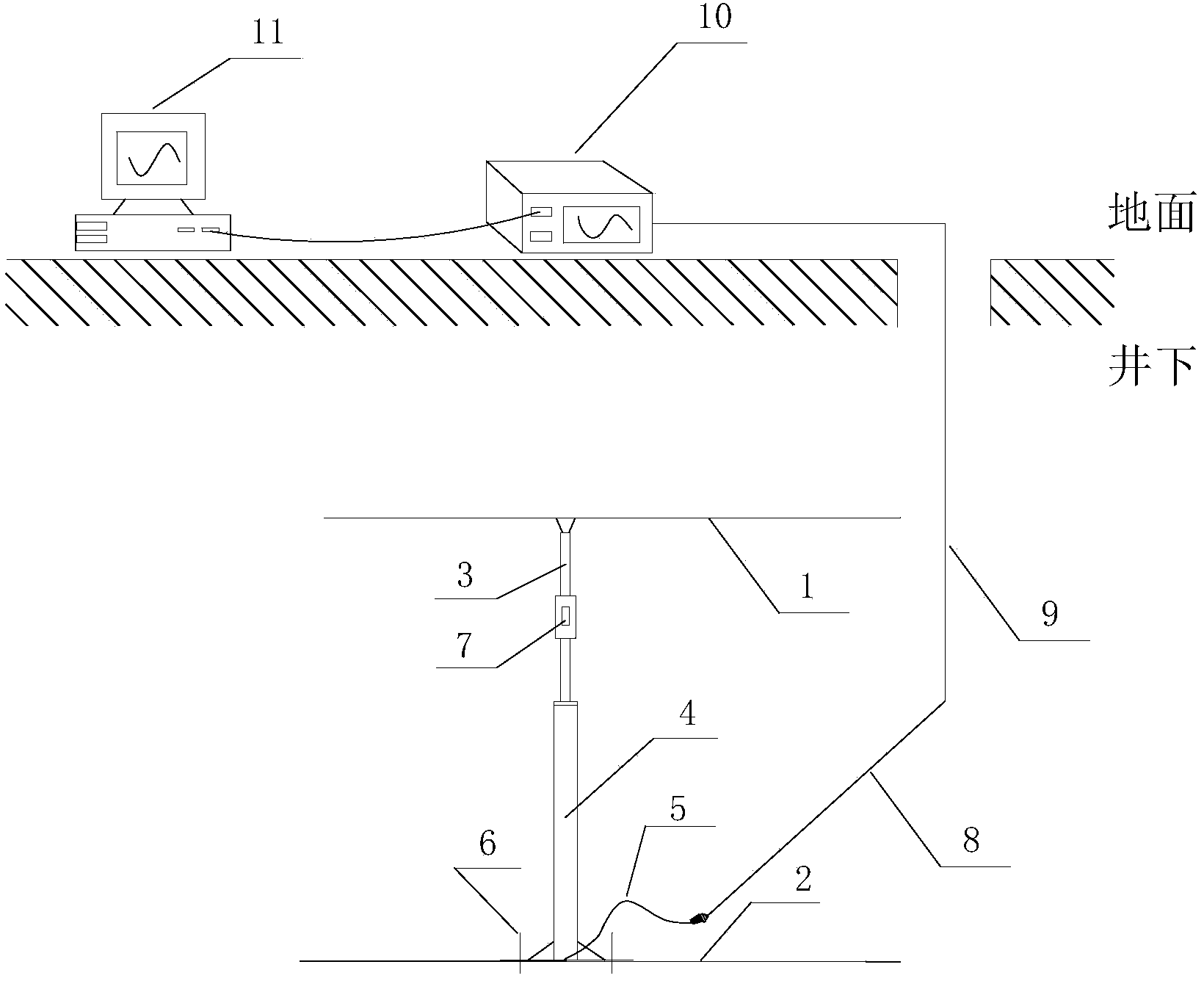

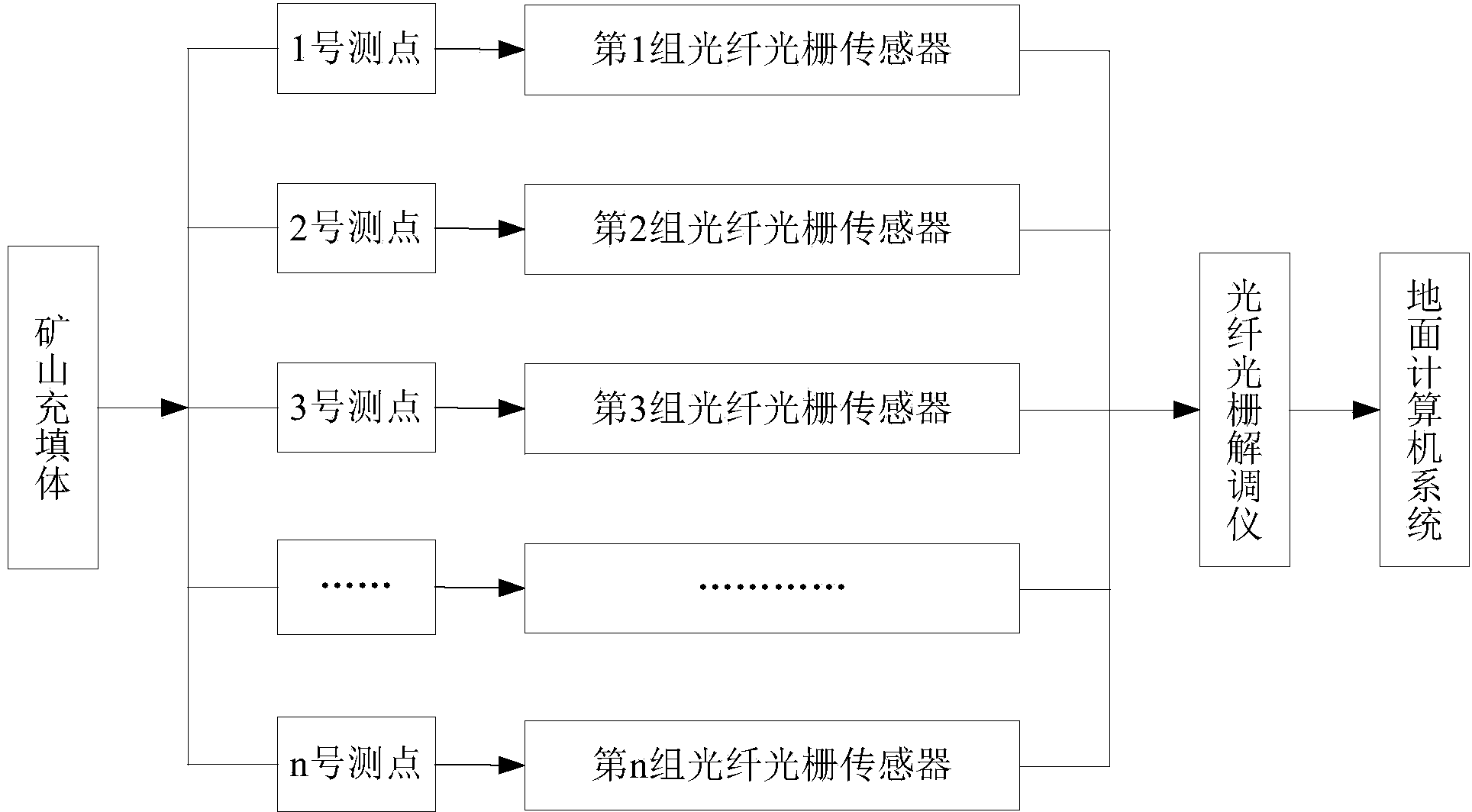

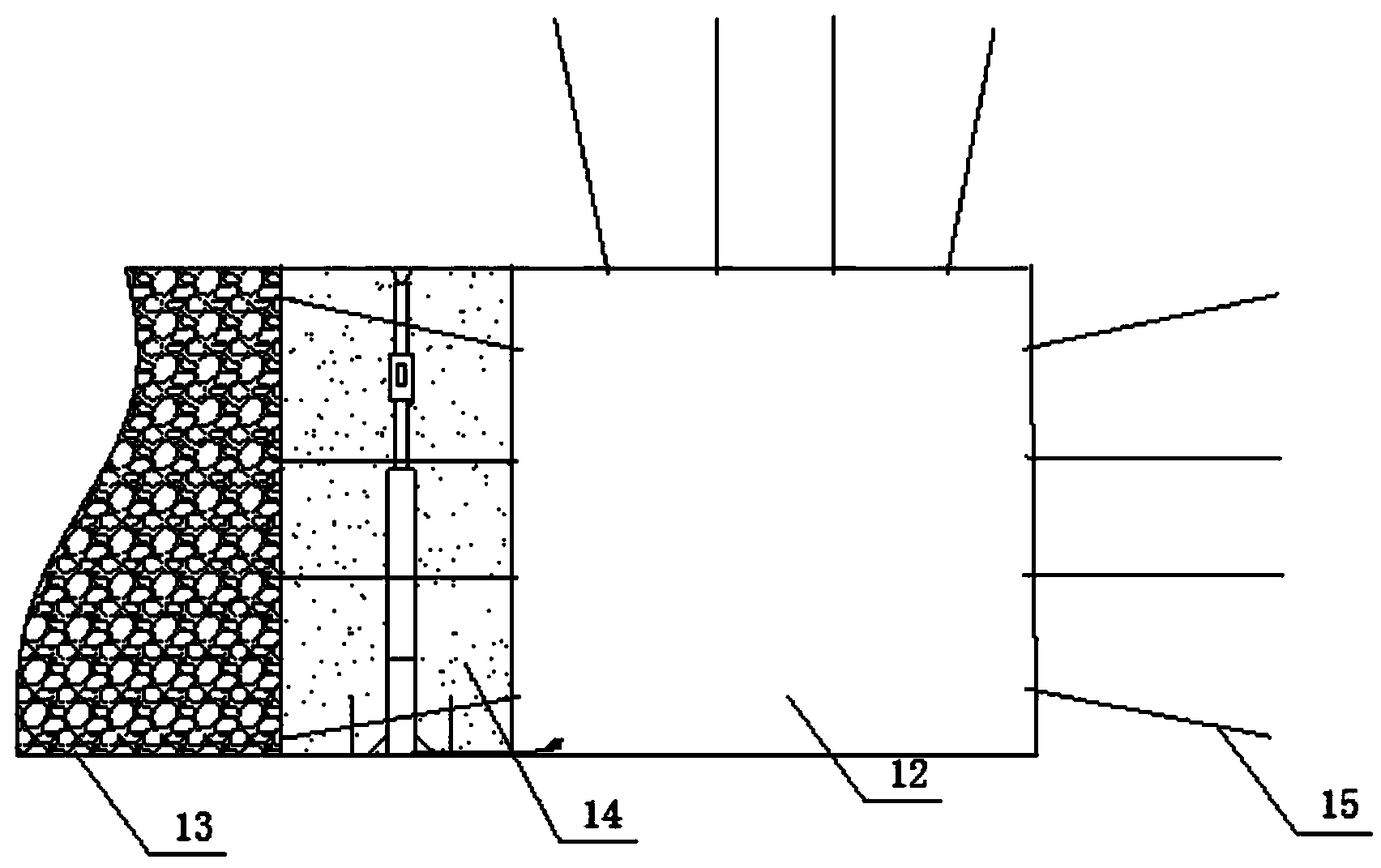

[0017] Example 1: In figure 1 Among them, the system includes: telescopic rod 3, support rod 4, optical fiber connector 5, ground anchor 6, fiber grating sensor group 7, optical fiber 8, mine optical cable 9, fiber grating demodulator 10 and computer system 11; Before the space at measuring point 16 is filled, the support rod 4 is fixed to the bottom plate 2 of the filling space through the ground anchor 6, the telescopic rod 3 telescopically supports the top plate 1 of the filling space, the fiber grating sensor group 7 is installed in the middle of the telescopic rod 3, and the tail of the support rod 4 is drawn out The optical fiber connector 5 is connected to the mine optical cable 9 through the optical fiber 8, and the mine optical cable 9 is connected to the fiber grating demodulator 10, so that the grating monitoring signal is transmitted to the fiber grating demodulator 10, and the fiber grating demodulator 10 is connected to the computer The system 11 is connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com