Adsorption and catalytic oxidation energy-saving system applied to waste gas treatment and control method

A catalytic oxidation and exhaust gas treatment technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of difficult equipment debugging, operation and maintenance, troublesome equipment installation, high operating costs, etc., and achieve easy equipment debugging, operation and maintenance , low operating cost, and simple equipment installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

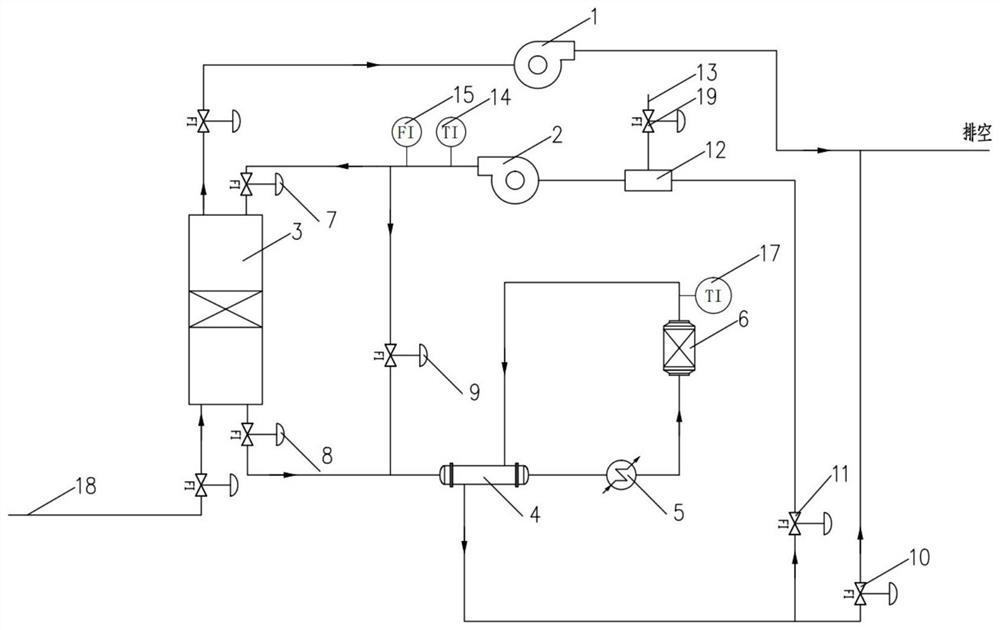

[0032] As a preferred implementation, the control method also includes a flow control process, controlling the flow of fresh air and internal circulating hot air according to the temperature and flow of the outlet gas of the desorption fan 2 .

[0033] As a preferred implementation, the control method further includes an internal circulation on-off control process, which controls the opening and closing of the internal circulation process according to the temperature of the hot gas at the outlet of the heat exchanger 4 .

[0034] A computer device, comprising a memory, a processor, and a computer program stored on the memory and operable on the processor, and the processor implements the following steps when executing the computer program:

[0035] Step 1, the adsorption stage, the waste gas to be treated is connected from the waste gas inlet pipe 18, passes through the adsorption concentration equipment 3, the adsorption fan 1 in sequence, and then is emptied;

[0036] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com