Method for reducing tin content of titanium tetrachloride

A technology of titanium tetrachloride and tin tetrachloride, applied in the direction of titanium tetrachloride, tin chloride, titanium halide, etc., can solve the problem of increasing the content of aluminum trichloride, the high price of trivalent titanium, and the impact on the production of sponge titanium, etc. problems, to achieve the effects of reducing energy consumption, simple equipment installation and production, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

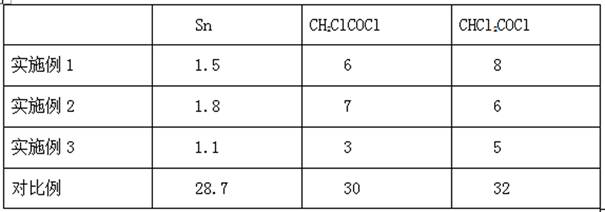

Embodiment 1

[0018] A method for reducing titanium tin tetrachloride content, comprising the following steps:

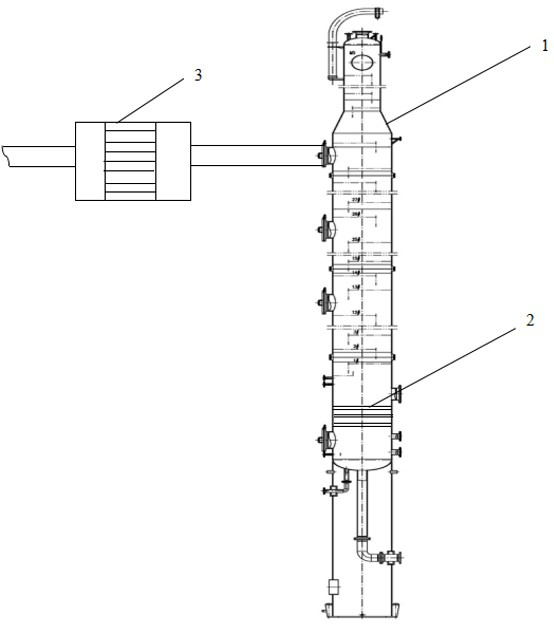

[0019] 1) An aluminum wire mesh 2 is added to the middle of the distillation tower 1, and the aluminum wire mesh 2 is provided with 3 layers, and the density of the aluminum wire mesh is 20-35 mesh;

[0020] 2) The temperature at the top of distillation tower 1 is controlled at 136°C, and titanium tetrachloride is sent into the distillation tower. Since tin tetrachloride has a lower boiling point than titanium tetrachloride, tin tetrachloride and tin tetrachloride are collected from the top of the distillation tower. The mixture of titanium tetrachloride, titanium tetrachloride is collected at the bottom of the distillation column, and the rectification process reduces the reflux ratio;

[0021] 3) According to the tin content in titanium tetrachloride, control the feed rate, so that the content of titanium tetrachloride and tin tetrachloride at the bottom of the tower can meet t...

Embodiment 2

[0025] A method for reducing titanium tin tetrachloride content, comprising the following steps:

[0026] 1) An aluminum wire mesh 2 is added to the middle of the distillation tower 1, and the aluminum wire mesh 2 is provided with 3 layers, and the density of the aluminum wire mesh is 20-35 mesh;

[0027] 2) The temperature at the top of distillation tower 1 is controlled at 145°C, and titanium tetrachloride is sent into the distillation tower. Since the boiling point of tin tetrachloride is lower than that of titanium tetrachloride, tin tetrachloride and The mixture of titanium tetrachloride, titanium tetrachloride is collected at the bottom of the distillation column, and the rectification process reduces the reflux ratio;

[0028] 3) According to the tin content in titanium tetrachloride, control the feed rate, so that the content of titanium tetrachloride and tin tetrachloride at the bottom of the tower can meet the production requirements of sponge titanium;

[0029] 4) ...

Embodiment 3

[0032] A method for reducing titanium tin tetrachloride content, comprising the following steps:

[0033] 1) An aluminum wire mesh 2 is added to the middle of the distillation tower 1, and the aluminum wire mesh 2 is provided with 3 layers, and the density of the aluminum wire mesh is 20-35 mesh;

[0034] 2) The temperature at the top of distillation tower 1 is controlled at 155°C, and titanium tetrachloride is sent into the distillation tower. Since the boiling point of tin tetrachloride is lower than that of titanium tetrachloride, tin tetrachloride and tin tetrachloride are collected at the top of the distillation tower. The mixture of titanium tetrachloride, titanium tetrachloride is collected at the bottom of the distillation column, and the rectification process reduces the reflux ratio;

[0035] 3) According to the tin content in titanium tetrachloride, control the feed rate, so that the content of titanium tetrachloride and tin tetrachloride at the bottom of the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com