Method for preventing and controlling heat hazard of mine

A technology of mine and evaporative heat exchanger, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc. It can solve the problems of increasing the workload of cooling and cooling, failing to achieve obvious cooling, repeated cooling and cooling, etc., to achieve Eliminate mine heat damage, easy equipment installation, high energy efficiency ratio of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

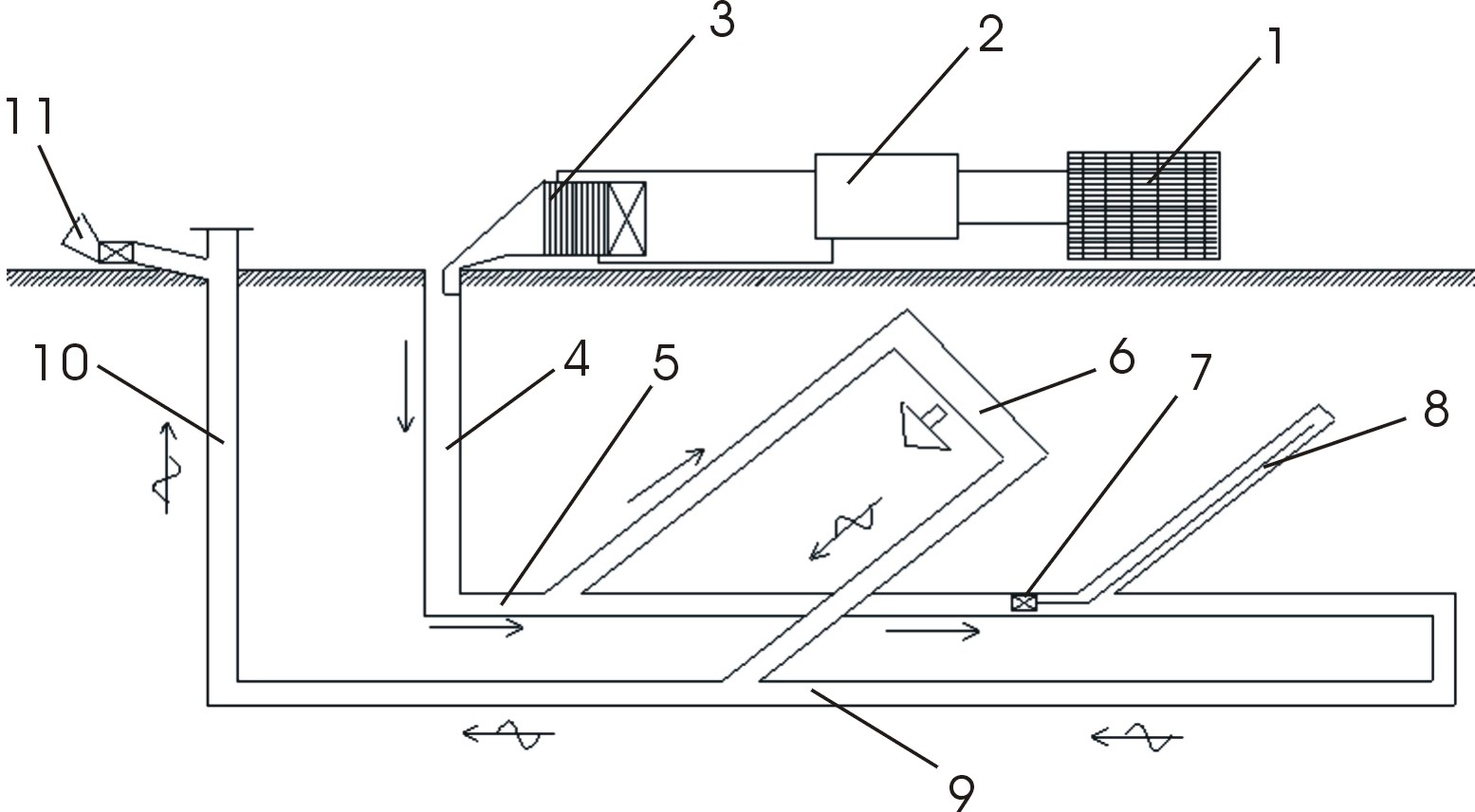

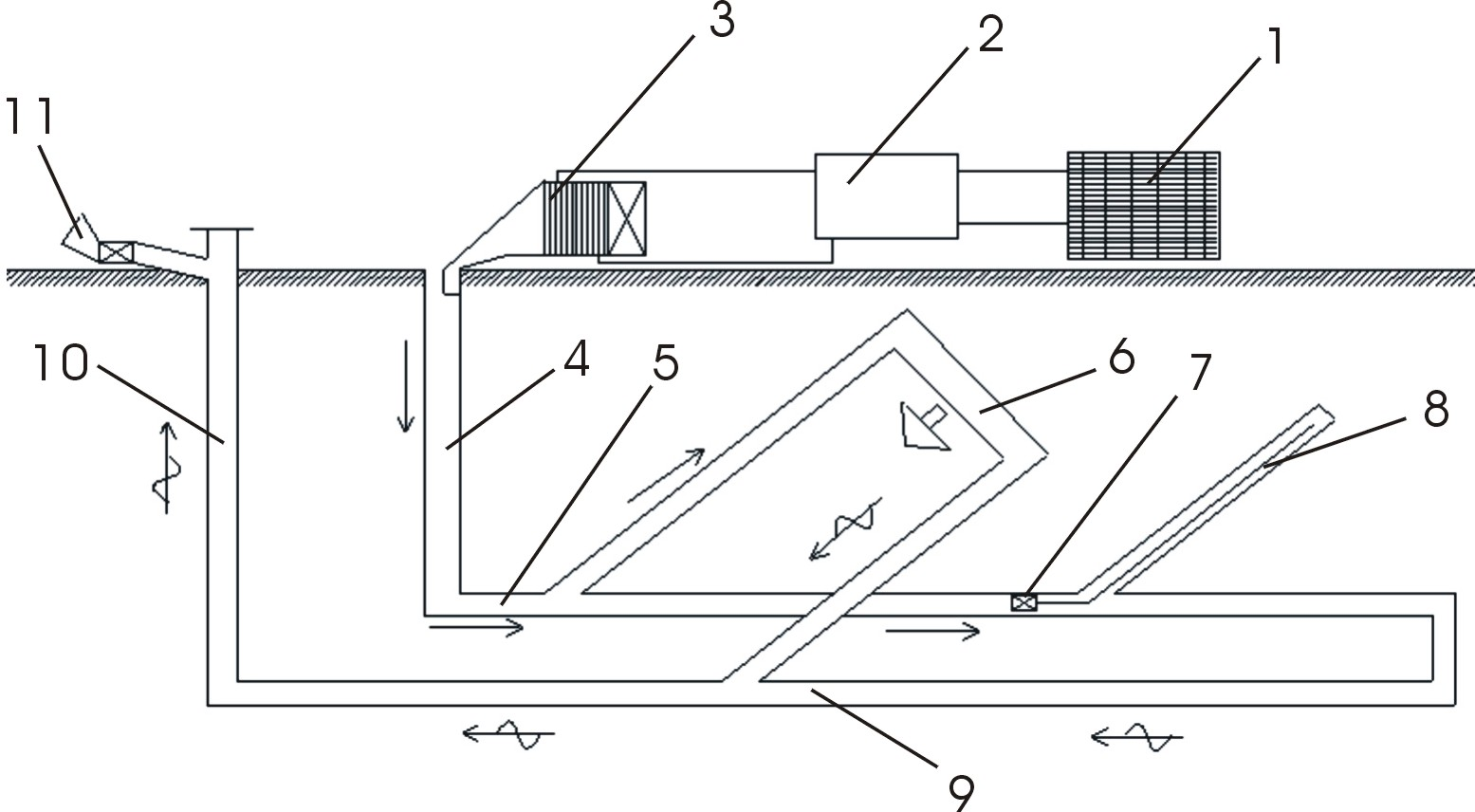

[0007] Now refer to the attached figure 1 , described in conjunction with the examples as follows: A method for preventing and controlling mine heat damage according to the present invention is to directly use a high-efficiency refrigeration unit to cool a part of the air entering the mine, and then mix it with other air entering the mine to form low-temperature air. , Through the existing mine ventilation system, it is sent to the underground working place to prevent and eliminate the hazards of underground high temperature and high humidity, and to improve the underground operating environment. The device adopted in the present invention includes a cooling tower 1, a refrigeration unit 2, an evaporative heat exchanger 3, an air inlet shaft 4, an air inlet roadway 5, a coal mining face 6, a local fan 7, an excavation face 8, a mine return Air lane 9, air return shaft 10 and mine main ventilator 11 form. Set up the refrigeration unit 2 on the ground, the refrigeration unit 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com