Transferring and conveying device for aluminum plate production line

A transfer conveying and production line technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of increasing working hours, reducing production efficiency, low economic benefits, etc., to prolong service life, improve production efficiency, The effect of improving connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to prevent the wear of the aluminum plate and the scratches between the worn aluminum plate and people, protect the safety of the staff, company property and employee property, and ensure the normal work of the site, the transfer and transportation process must implement the policy of "safety first, prevention first" to reduce The damage of the aluminum plate and the transfer conveying device during the work process protects the personal and property safety of the production and on-site staff.

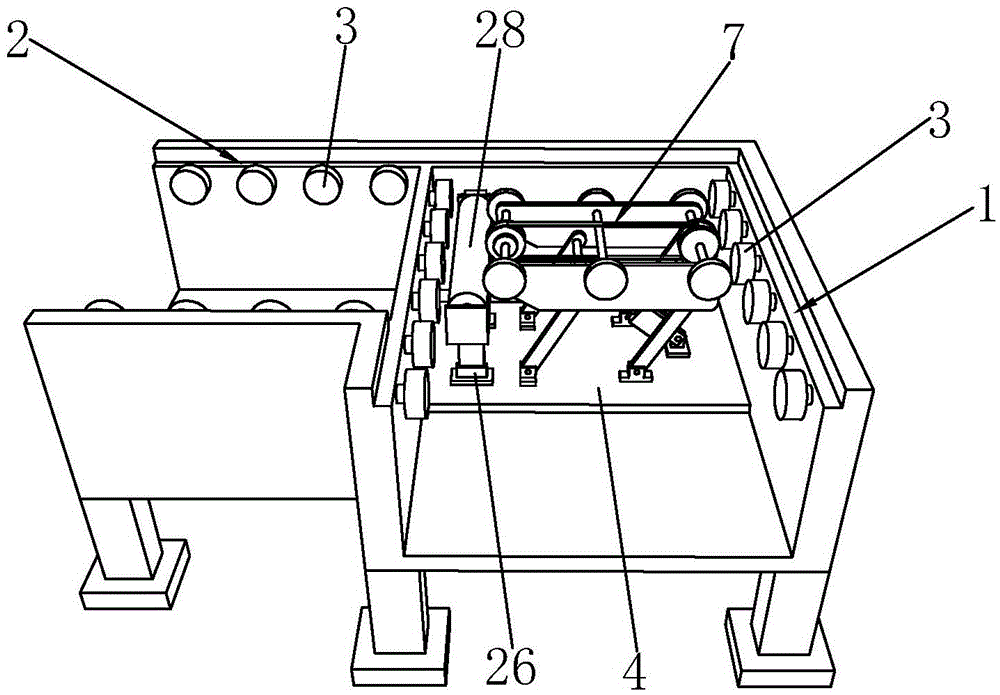

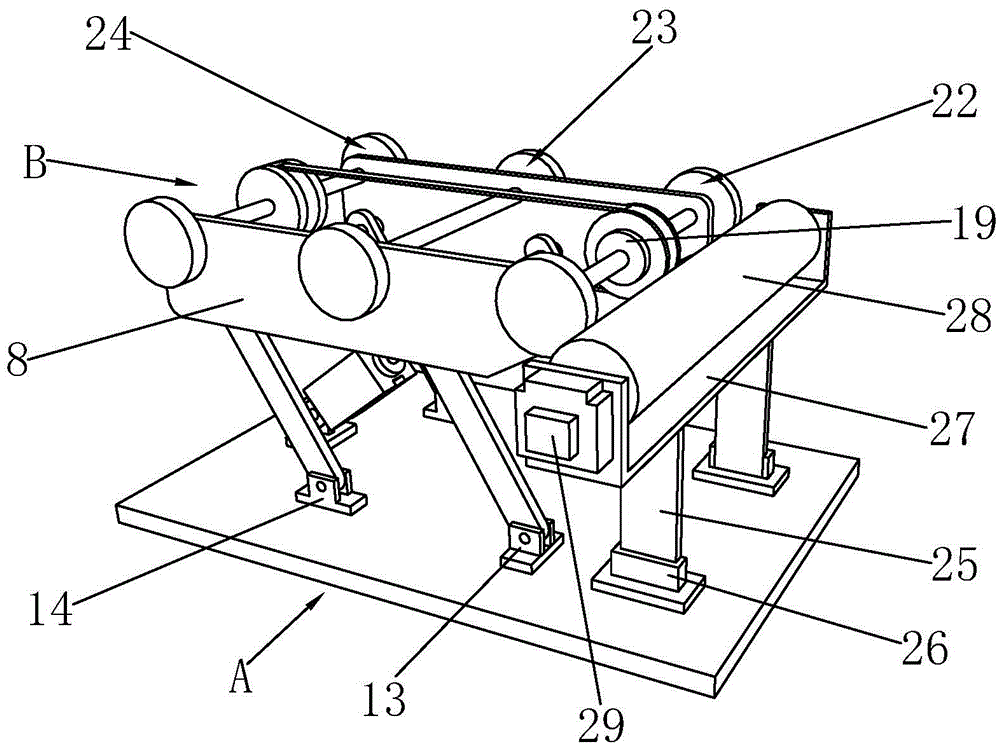

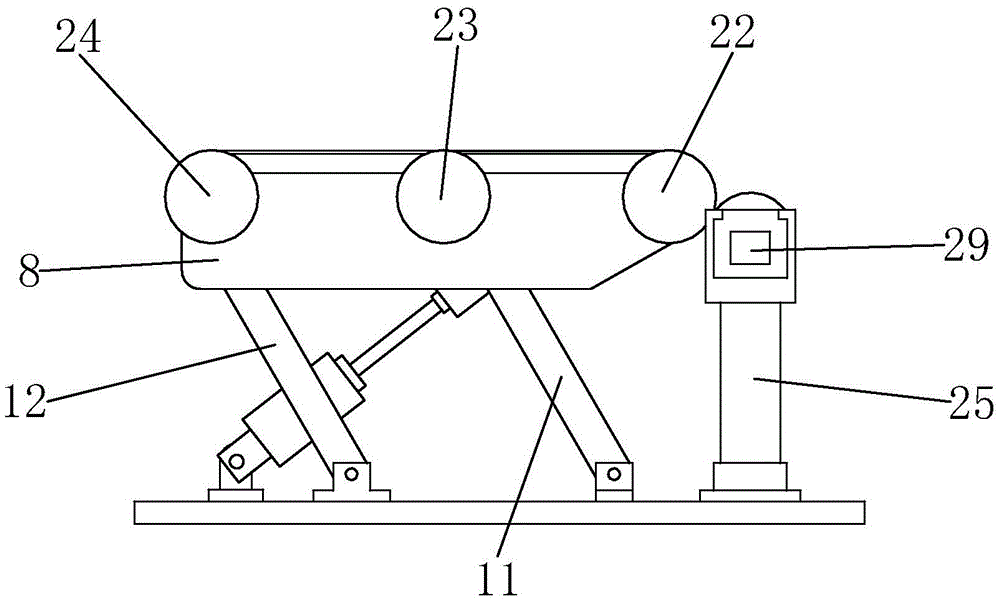

[0026] Such as Figure 1 to Figure 6As shown, it is a transfer conveying device used in the aluminum plate production line of the present invention, including a first conveying mechanism 1 and a second conveying mechanism 2, and the angle between the first conveying mechanism 1 and the second conveying mechanism 2 is 90 degrees , the first conveying mechanism 1 and the second conveying mechanism 2 are equipped with conveying rollers 3, the surface of conveying rollers 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com