Processing method of power cable

A processing method and technology for power cables, which are applied in the manufacture of cables/conductors, insulating conductors/cables, and reducing the size of conductors/cables, etc., can solve the problem of reducing production costs, increasing the workload of production personnel, and increasing production personnel costs. Long-term operation and monitoring, etc., to prevent unqualified quality, ensure production quality, and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

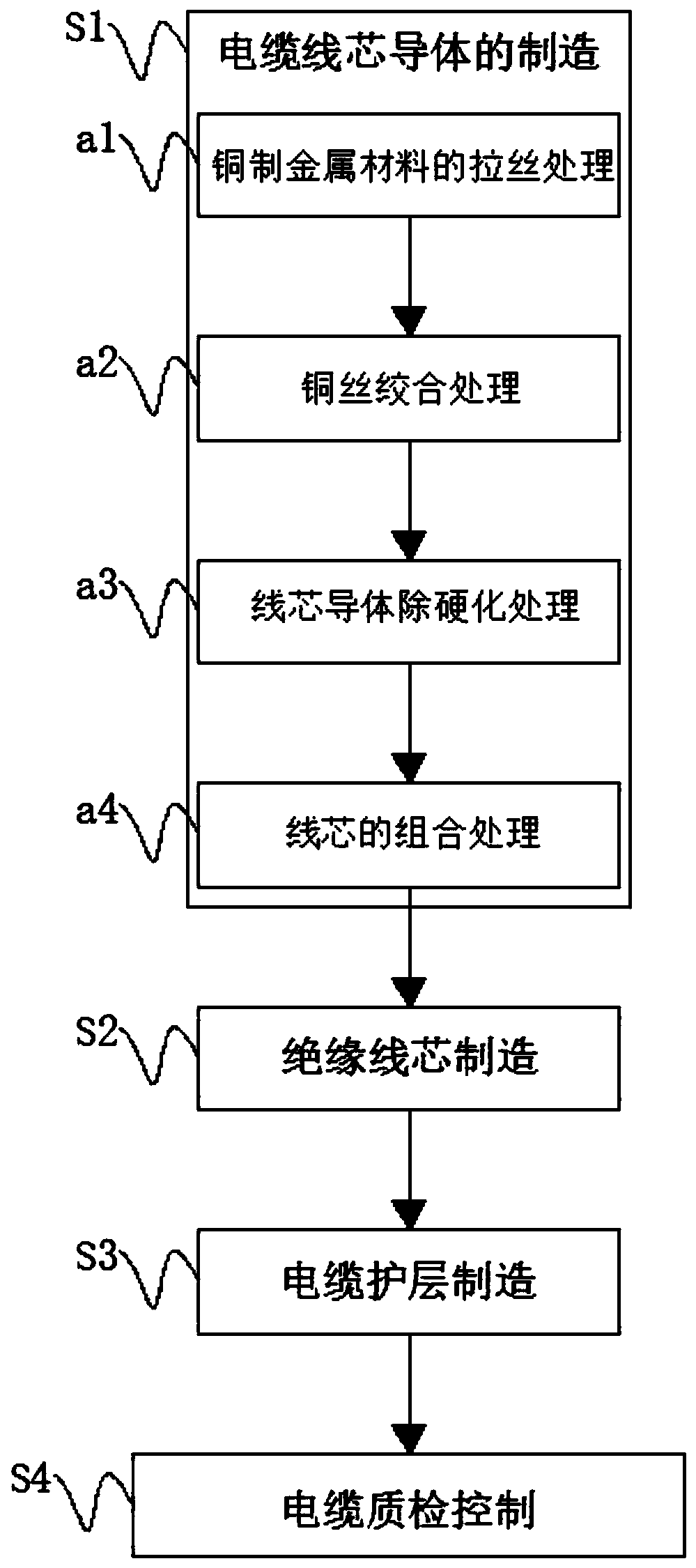

[0031] S1. Manufacture of cable core conductors: During the production of cable core conductors, it is necessary to select copper metal materials after removal of impurities as the core conductor base material, and then carry out the following processing procedures for production and manufacturing:

[0032] a1. Wire drawing treatment of copper metal materials: firstly, the selected copper metal materials are drawn through a wire drawing machine, and the single wire is thinned to the required diameter. After the copper metal materials are processed by the wire drawing machine, the metal materials are drawn into a fine copper wire with a diameter of 0.4mm;

[0033] a2. Copper wire twisting treatment: Twist and twist the multiple single wires drawn in step a1 together through a twisting machine, and use a tight hoop to hold and fix the twisted copper wires. The tight hoop is made of steel Made of plastic materials, the upper and lower hoops are connected and fixed by fastening sc...

Embodiment 2

[0040] S1. Manufacture of cable core conductors: During the production of cable core conductors, it is necessary to select copper metal materials after removal of impurities as the core conductor base material, and then carry out the following processing procedures for production and manufacturing:

[0041] a1. Wire drawing treatment of copper metal materials: firstly, the selected copper metal materials are drawn through a wire drawing machine, and the single wire is thinned to the required diameter. After the copper metal materials are processed by the wire drawing machine, the metal materials are drawn into a fine copper wire with a diameter of 0.3mm;

[0042] a2. Copper wire twisting treatment: Twist and twist the multiple single wires drawn in step a1 together through a twisting machine, and use a tight hoop to hold and fix the twisted copper wires. The tight hoop is made of steel Made of plastic materials, the upper and lower hoops are connected and fixed by fastening sc...

Embodiment 3

[0049] S1. Manufacture of cable core conductors: During the production of cable core conductors, it is necessary to select copper metal materials after removal of impurities as the core conductor base material, and then carry out the following processing procedures for production and manufacturing:

[0050] a1. Wire drawing treatment of copper metal materials: firstly, the selected copper metal materials are drawn through a wire drawing machine, and the single wire is thinned to the required diameter. After the copper metal materials are processed by the wire drawing machine, the metal materials are drawn into a fine copper wire with a diameter of 0.5mm;

[0051] a2. Copper wire twisting treatment: Twist and twist the multiple single wires drawn in step a1 together through a twisting machine, and use a tight hoop to hold and fix the twisted copper wires. The tight hoop is made of steel Made of plastic materials, the upper and lower hoops are connected and fixed by fastening sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com