Patents

Literature

49results about How to "Convenient quality inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

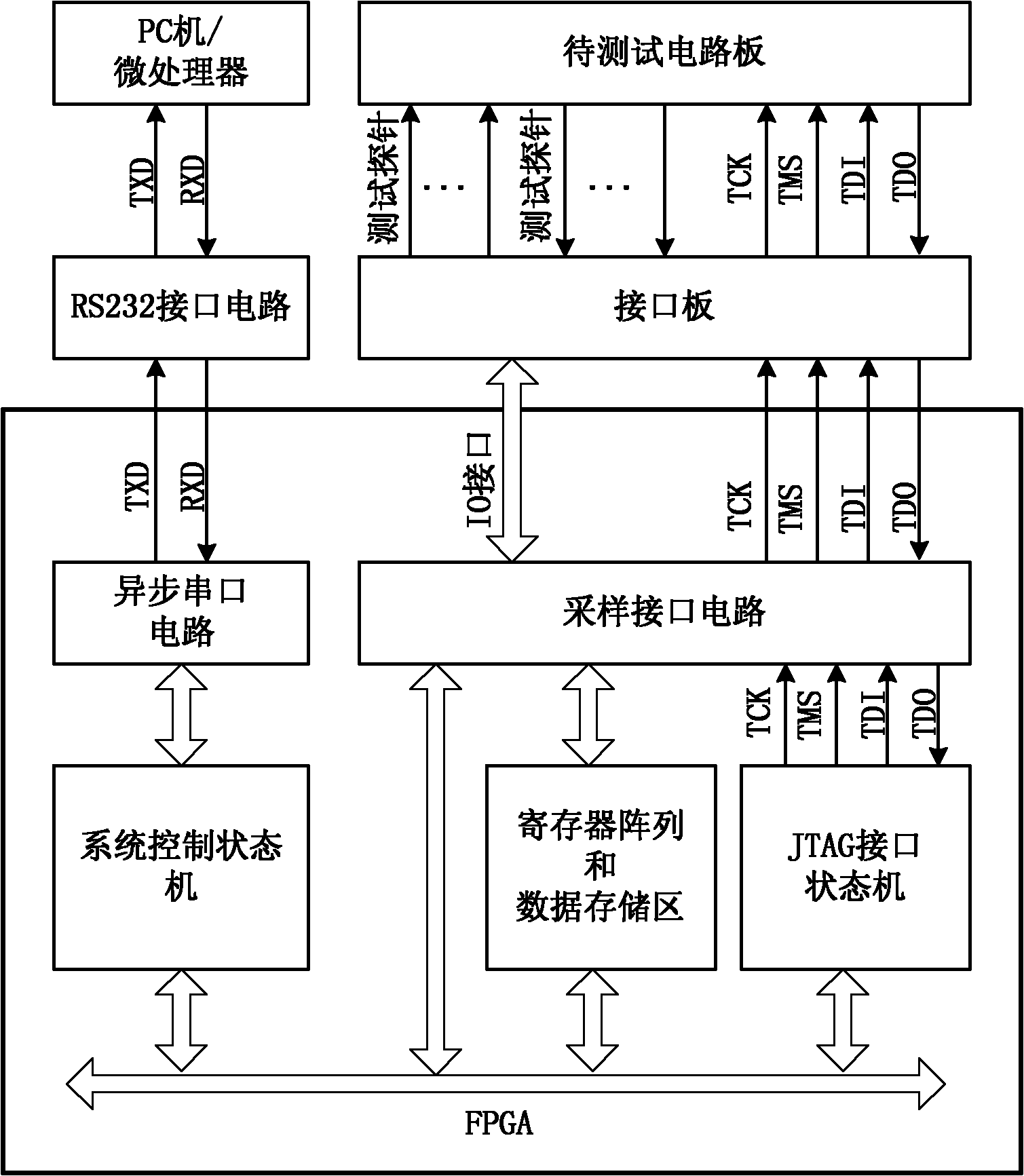

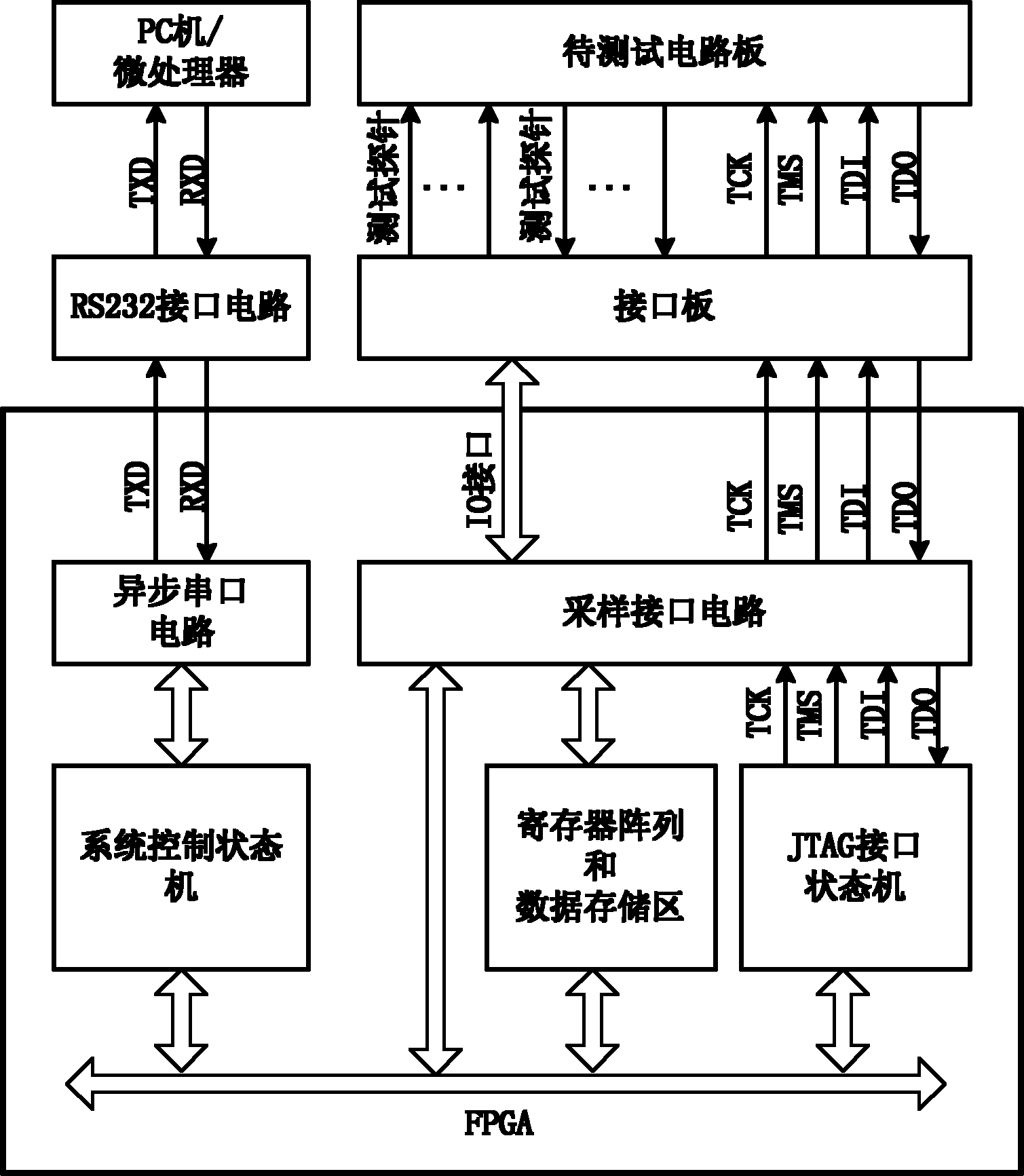

FPGA-based JTAG test method

InactiveCN101980036AGood flexibilityGood accuracyElectrical testingProgramme control in sequence/logic controllersWelding defectPersonal computer

The invention relates to a field programmable gate array (FPGA)-based joint test action group (JTAG) test method. In the method, an FPGA is connected with a circuit board to be tested by a JTAG interface and a probe; when a test is performed through the JTAG interface, the probe led out of the FPGA is connected with a monitoring point of the circuit board to be tested so as to read the data change of each point during the test; and finally, the FPGA sends the data change to a personal computer (PC) or a microprocessor for data analysis and judgment through an asynchronous series-port circuit. By the FPGA-based JTAG test method, a welding defect of a ball grid array (BGA) chip and the welding condition of the circuit around the chip can be precisely judged.

Owner:FUJIAN XINO COMM TECH

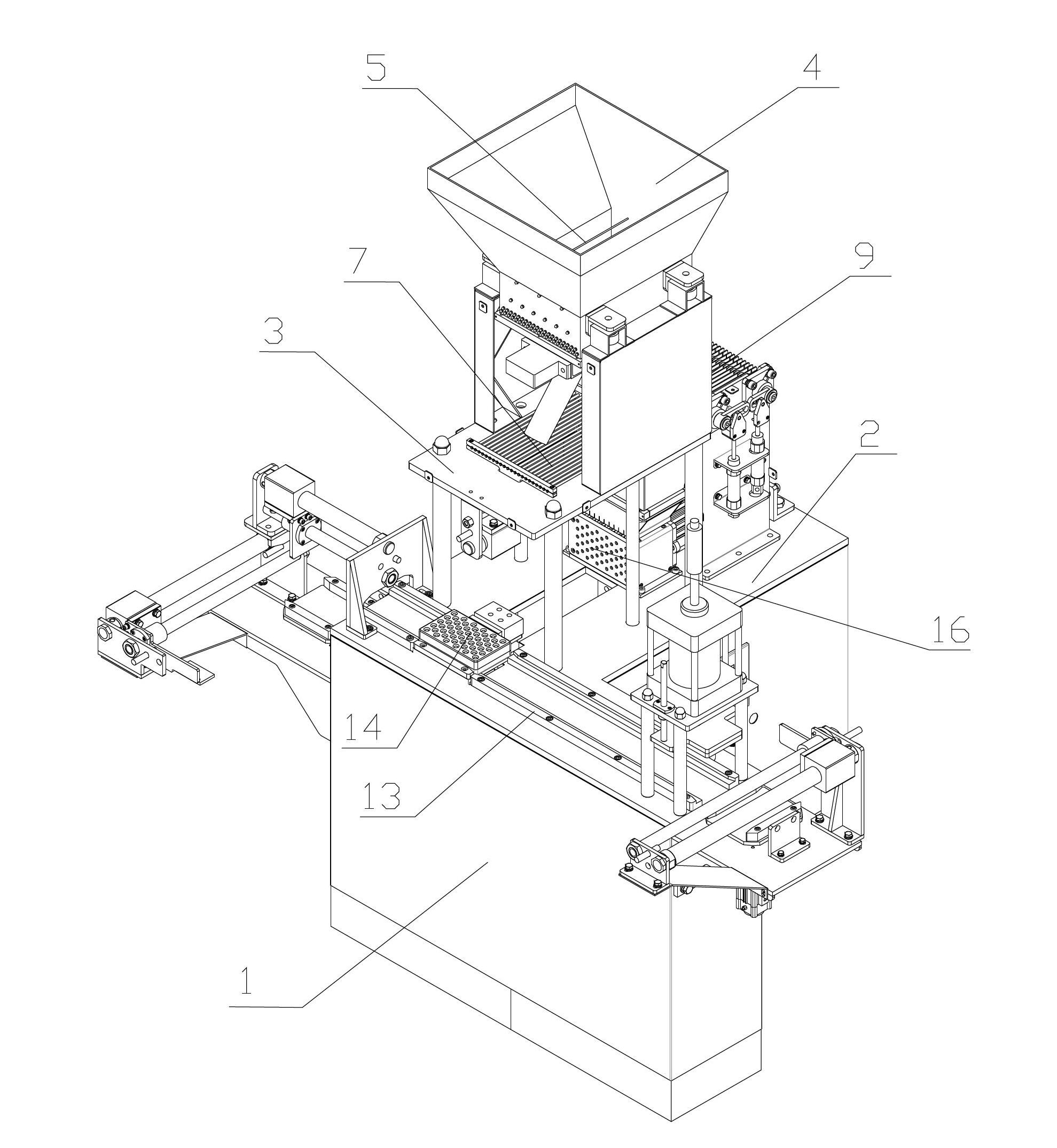

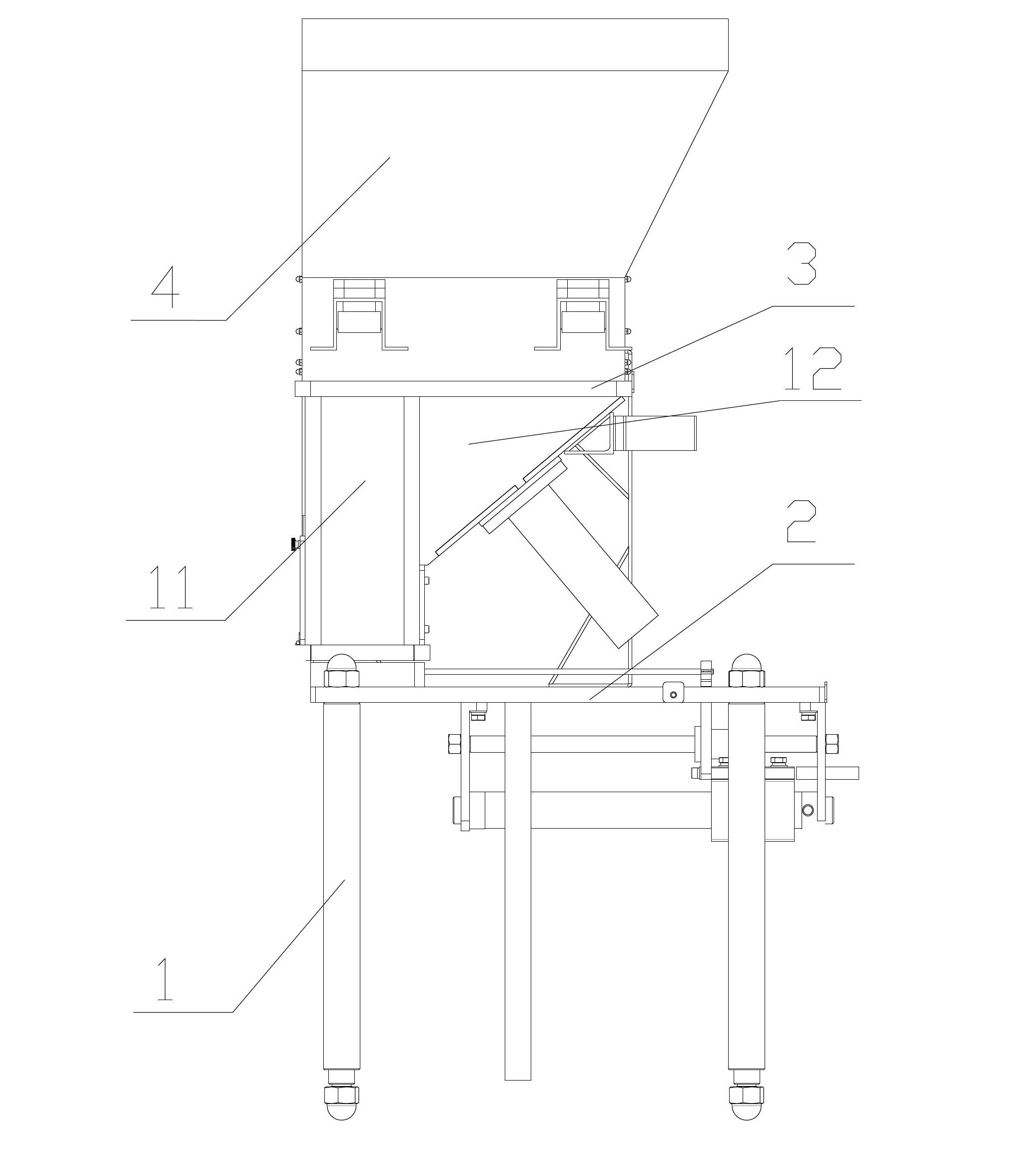

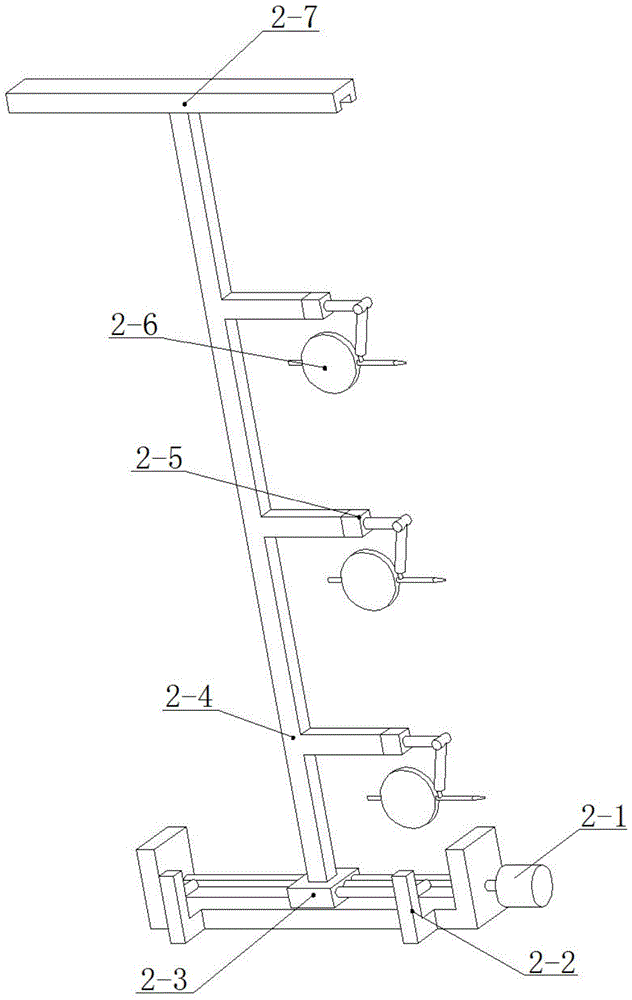

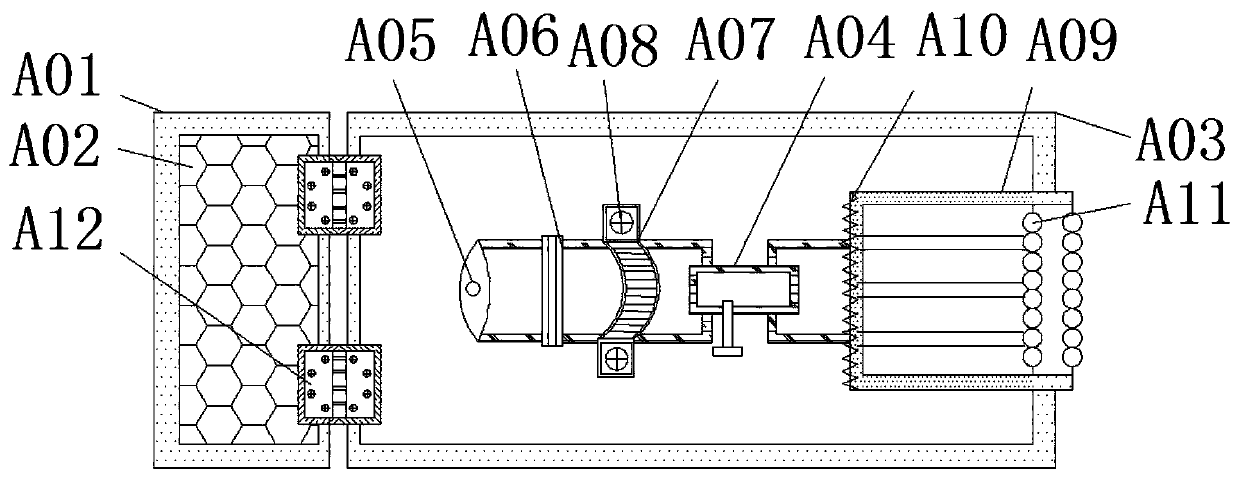

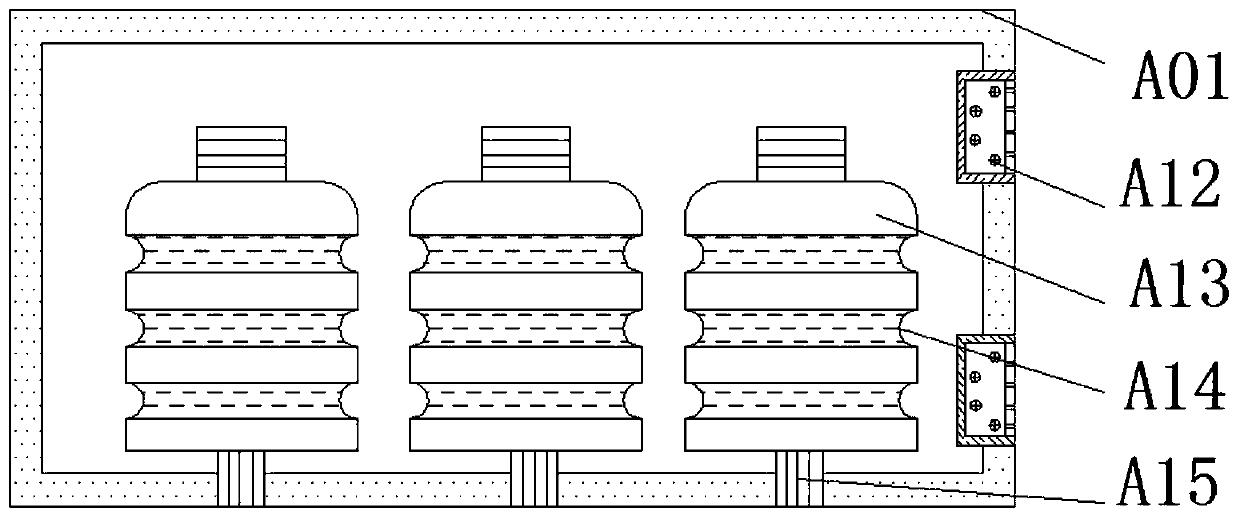

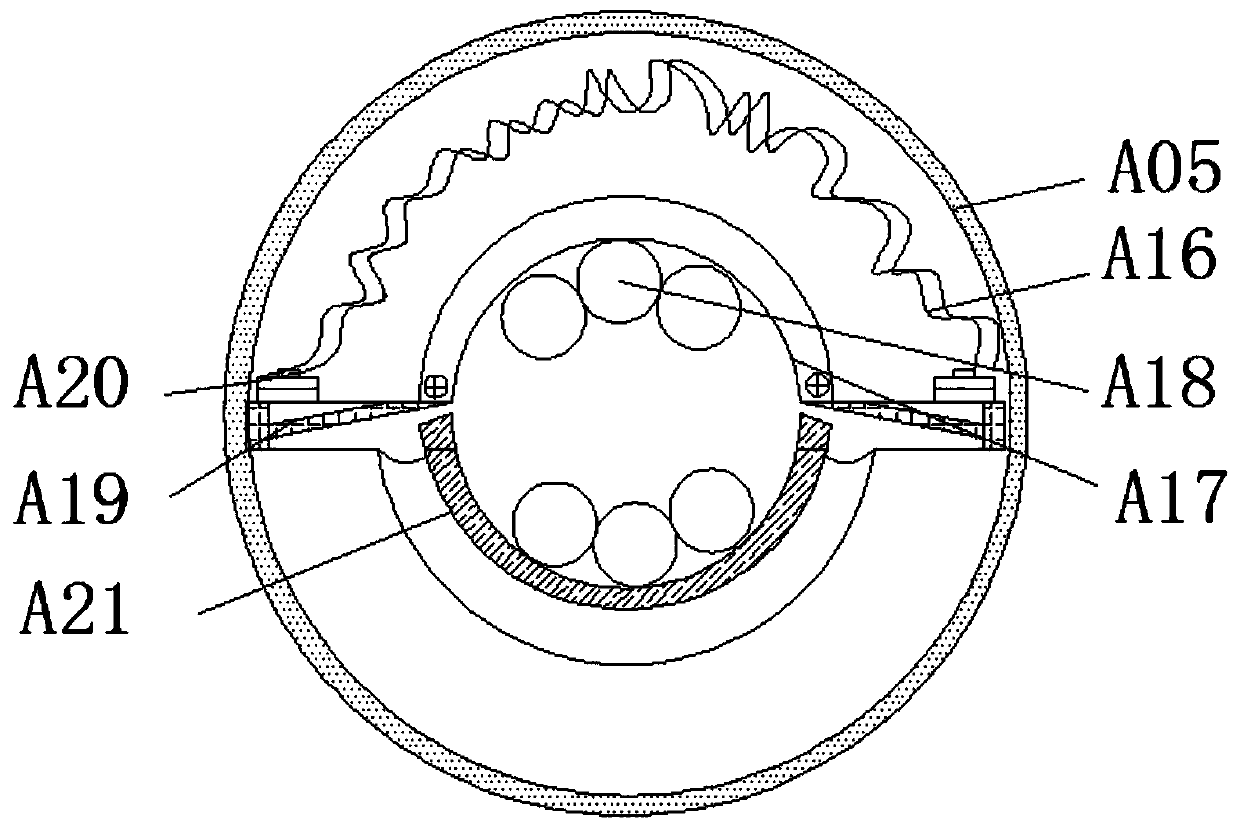

Automatic detonator arranging machine for detonator shells

ActiveCN102661687AImprove work efficiencyRealize fully automatic operationAmmunition fuzesDetonatorRange of motion

The invention provides an automatic detonator arranging machine for detonator shells. A detonator shell orientating device, a detonator shell adjusting device and a die filling device are arranged on a frame, wherein the detonator shell orientating device comprises a feed hopper, a separated detonator arranging collector and a detonator pushing mechanism; a plurality of transverse orientating steel wires are arranged on two opposite inner walls of the feed hopper; the lower opening of the feed hopper is connected with the upper end of the separated detonator arranging collector comprising a plurality of longitudinal orientating steel wires; the moving direction of a push rod of the detonator pushing mechanism is opposite to the gaps of the longitudinal orientating steel wires; the diameter of the push rod is not greater than the diameter of the detonator shells; forward turning fingers and reverse turning fingers which are arranged on the same horizontal plane, a positioning baffle and a retracting hopper are arranged in the moving range of the push rod; the lower end of the retracting hopper is connected with a detonator separating template; and positions and sizes of holes on a collecting die are matched with those of the holes on the detonator separating template. The automatic detonator arranging machine is full-automatic and is high in detonator feeding quality and high in speed; and the technical problems that the working efficiency is low, the detonator shells are blocked, the alignment precision is low, the detonators are infirmly inserted in the conventional detonator arranging machine and the like can be solved.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

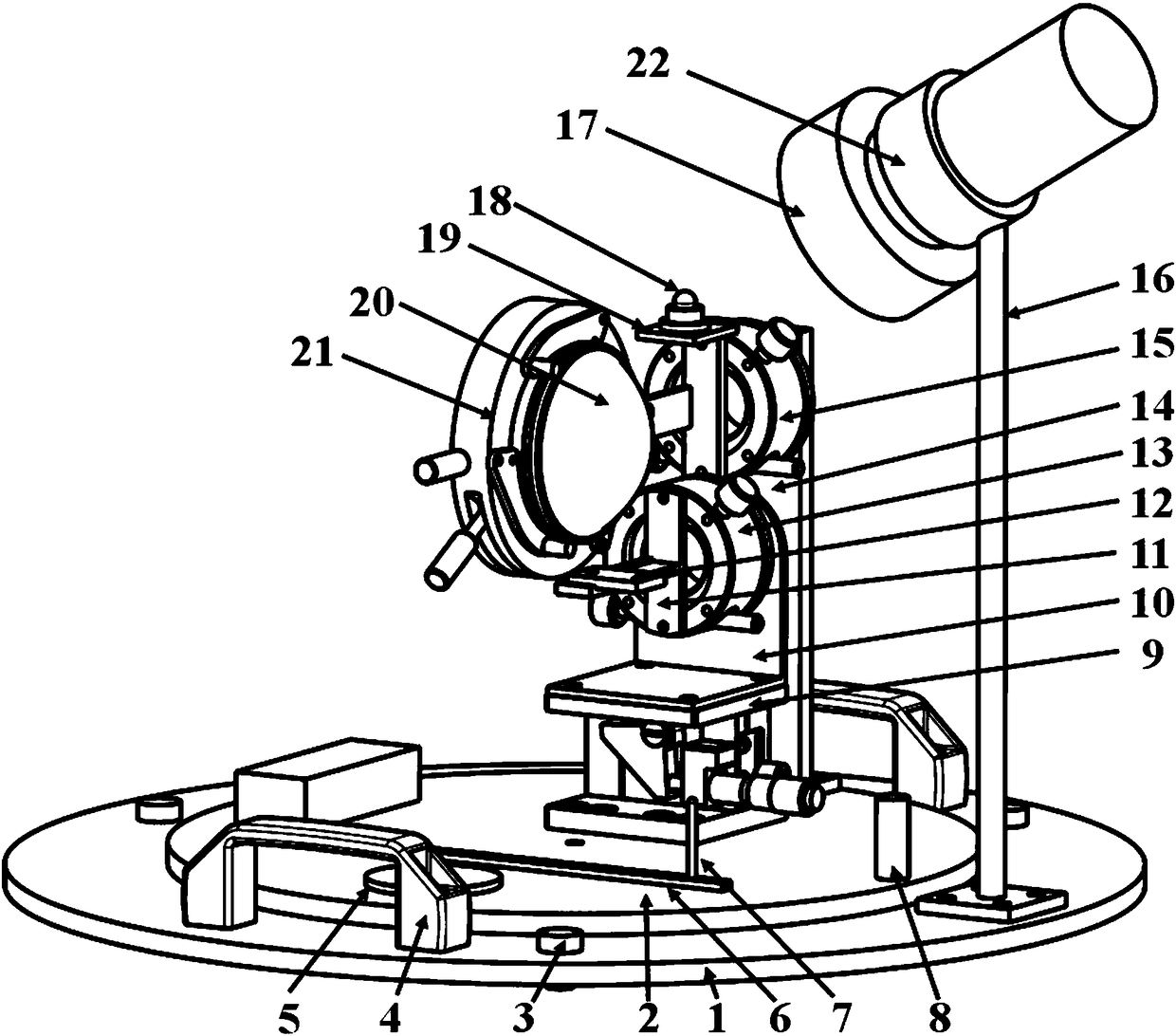

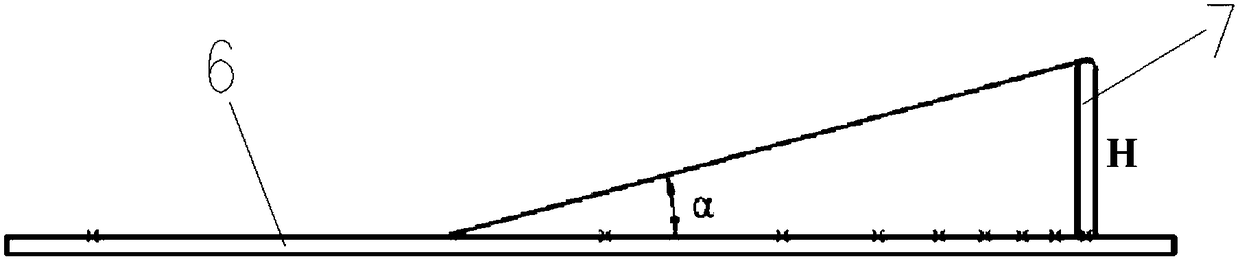

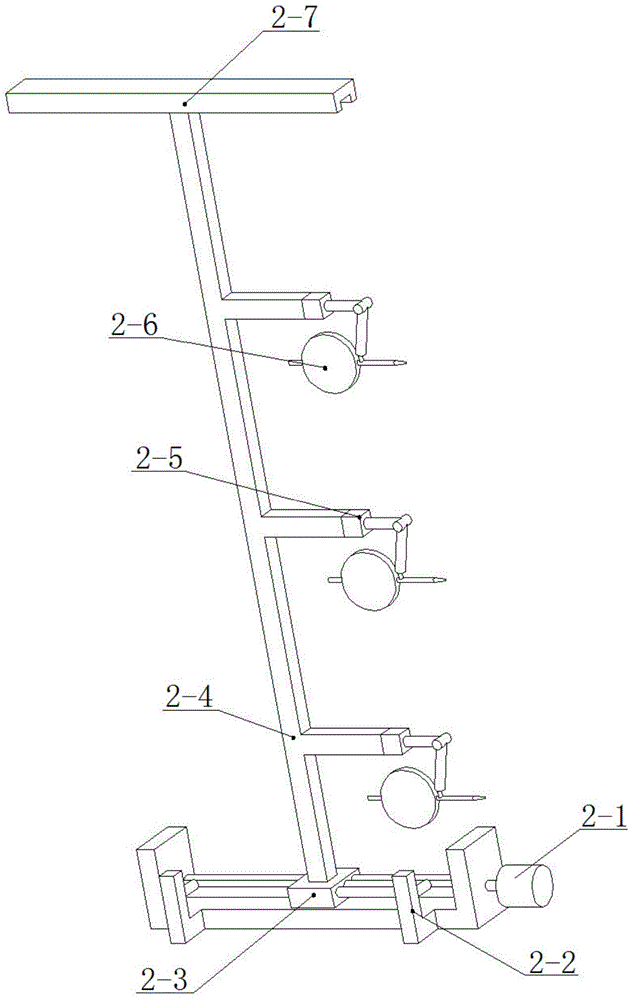

Vehicle lamp lens sunlight focus point detection device and use method thereof

PendingCN108572063AEasy to calculateAccurate calculationTesting alignment of vehicle headlampsRotary stageEngineering

The invention belongs to the technical field of vehicle lamp detection, in particular to a vehicle lamp lens sunlight focus point detection device and a use method thereof. The device comprises a base. A horizontal rotary bench is rotatably connected to the base. A lens adjustment mechanism and a sample piece adjustment mechanism are arranged on the horizontal rotary bench. The lens adjustment mechanism comprises a first support and a first precision rotary bench. The first support is fixed to the horizontal rotary bench. A clamping device is installed on the rotary part of the first precisionrotary bench. The sample piece adjustment mechanism comprises an elevating bench and a second precision rotary bench. The bench seat of the second precision rotary bench is fixed to the elevating bench. A fixed plate is fixed on the rotary part of the second precision rotary bench. The beneficial effects are that positions of reflection focus points and refraction focus points can be calculated;the calculation is precise; it is convenient to carry out analysis to obtain the safe distance where the lens is prevented from burning lamp materials; and after a thermal imager tests the reflectionfocus points and the refraction focus points, a precise and unique temperature value can be obtained.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

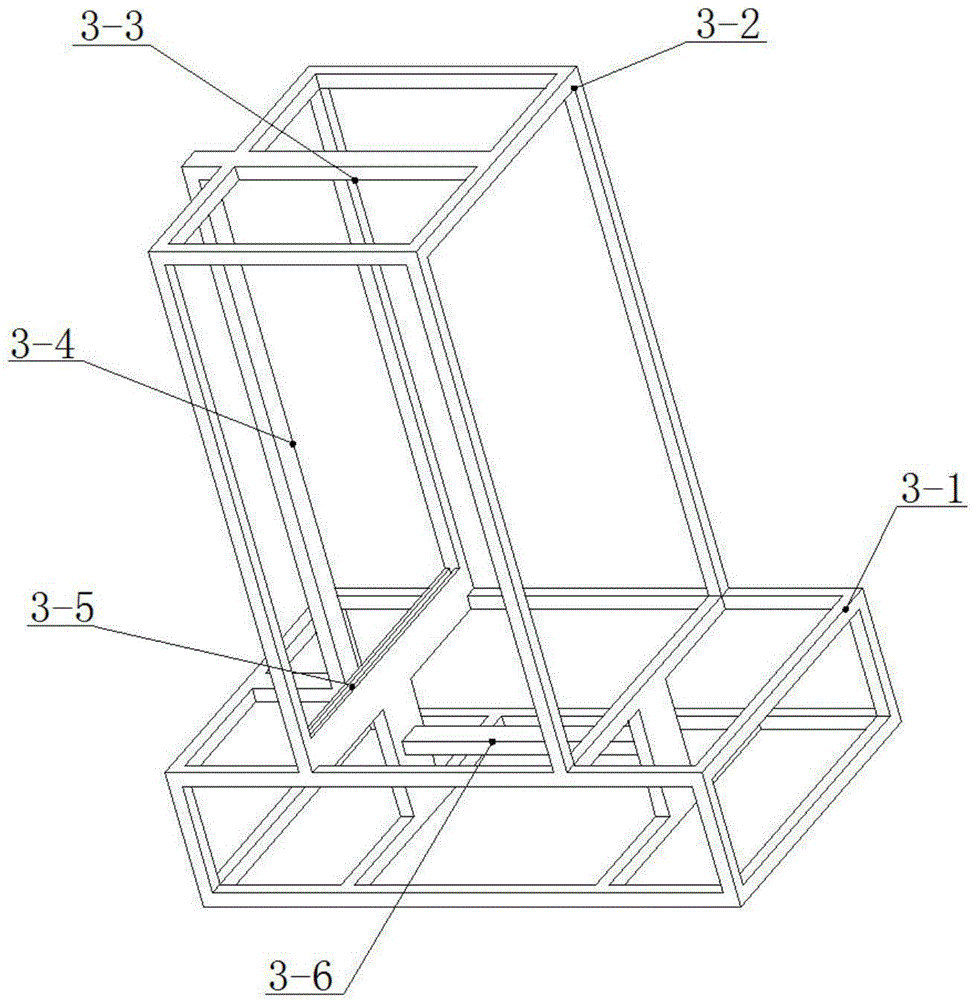

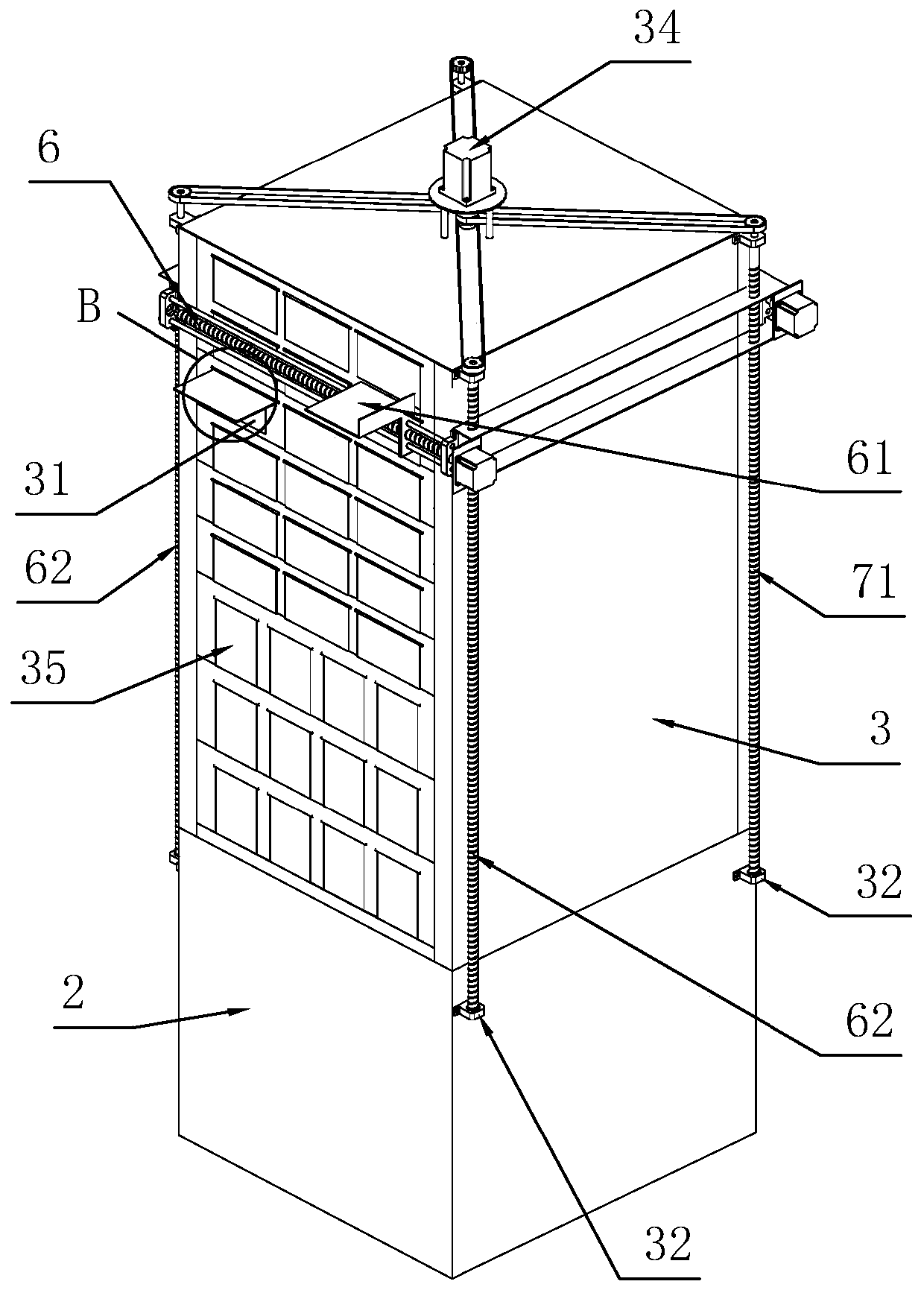

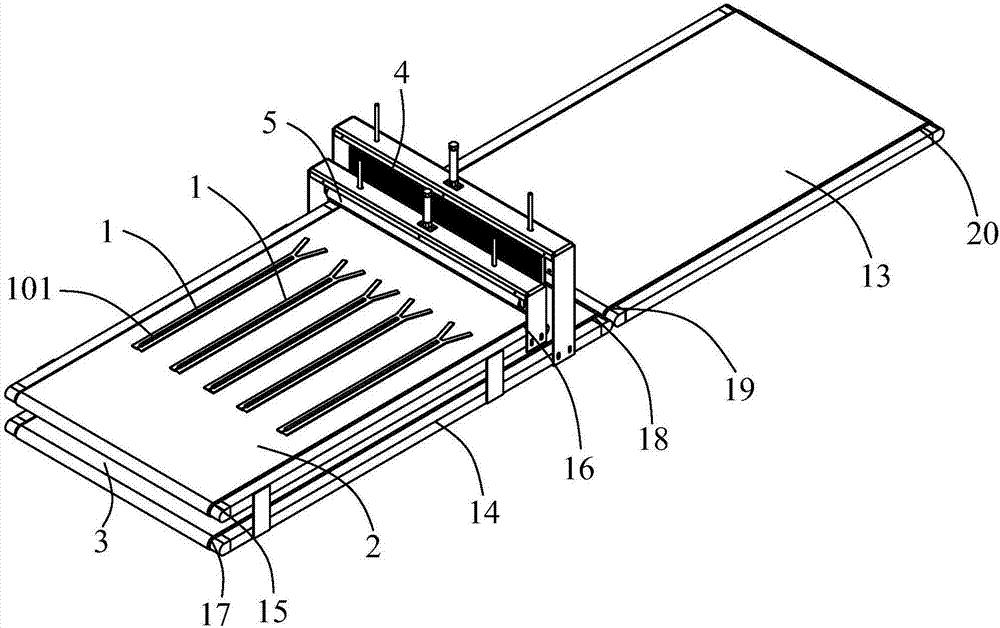

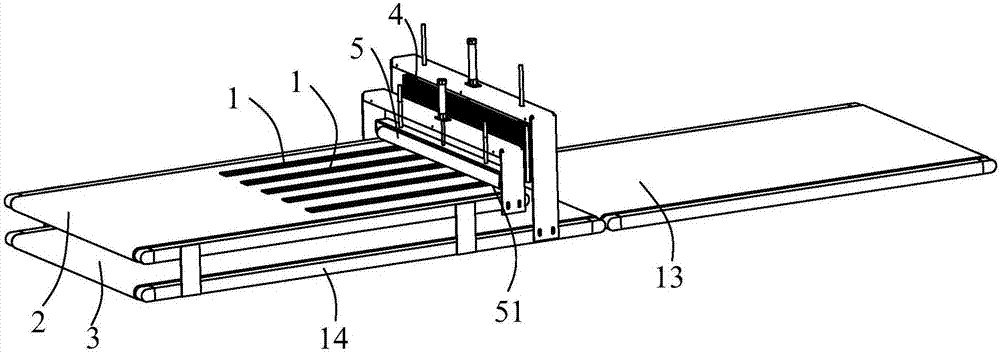

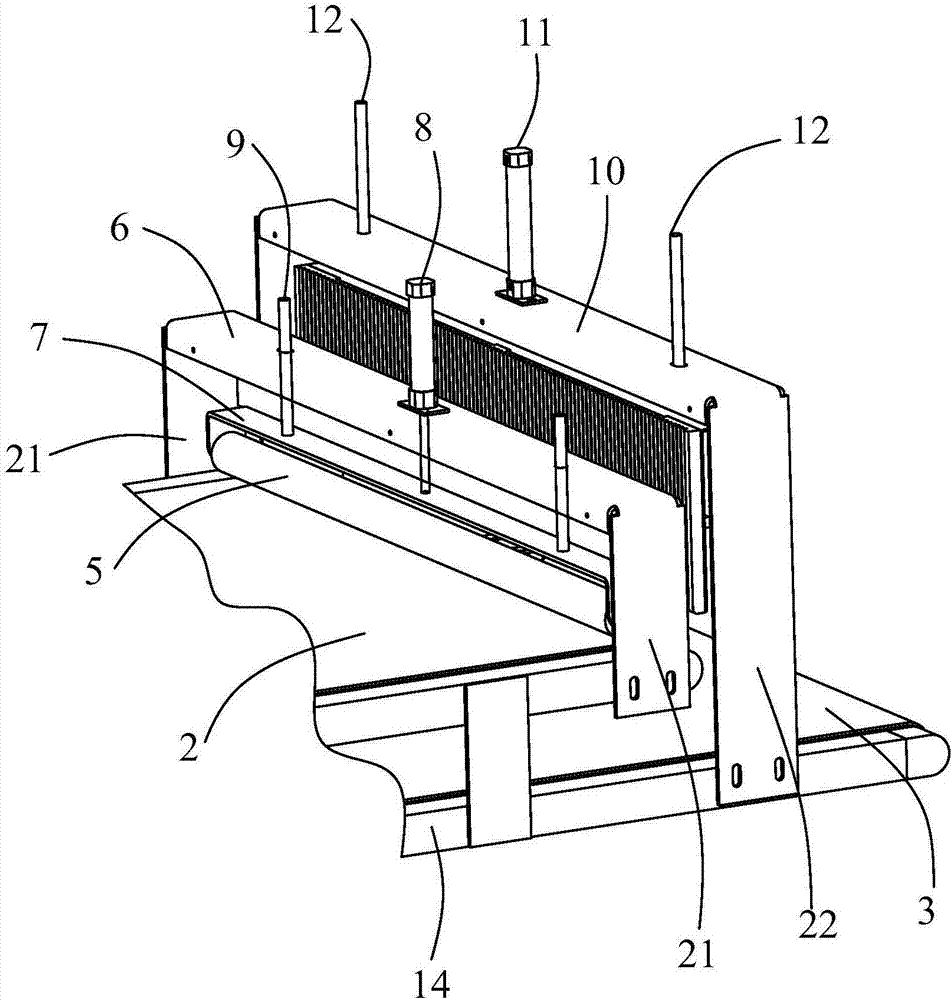

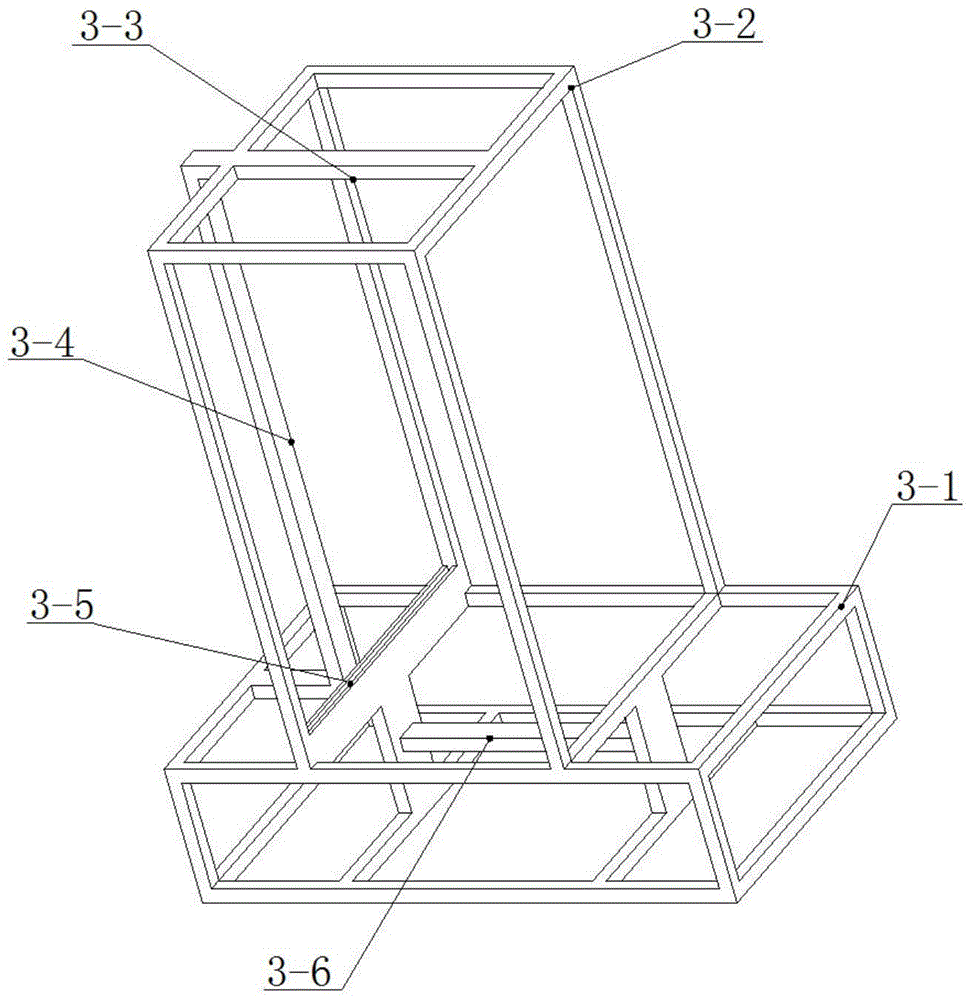

Quality detection device for door/window screen and using method thereof

ActiveCN104655444AEasy to set upThe test results are close to the realStructural/machines measurementDrive motorEngineering

The invention discloses a quality detection device for a door / window screen, belonging to the field of quality detection. The quality detection device disclosed by the invention comprises an overall frame, a screen clamping mechanism, a detection mechanism and a loading mechanism, wherein the screen clamping mechanism adjusts the relative height of a screen fixing rod on the overall frame by utilizing a tensioning mechanism; a screen fixing clamping groove is formed in the overall frame, and the upper and lower sides of a to-be-detected screen are clamped by virtue of the screen fixing clamping groove and the screen fixing rod; the detection mechanism comprises a driving motor, a lead screw sliding table, a support frame, a detection meter bracket, a digital indicator and a sliding rail; the lead screw sliding table is driven by the driving motor and is used for driving the support frame to move along the horizontal direction; a measuring head of the digital indicator faces the to-be-detected screen, and the digital indicator is positioned in the middle of the to-be-detected screen; and the loading mechanism hooks the to-be-detected screen by virtue of a hook so as to realize tension loading of the to-be-detected screen. The special detection device and method are designed according to the screen detection standard, the structure is simple, the detection is convenient, and the intelligent degree is high.

Owner:常州常工院技术转移有限公司

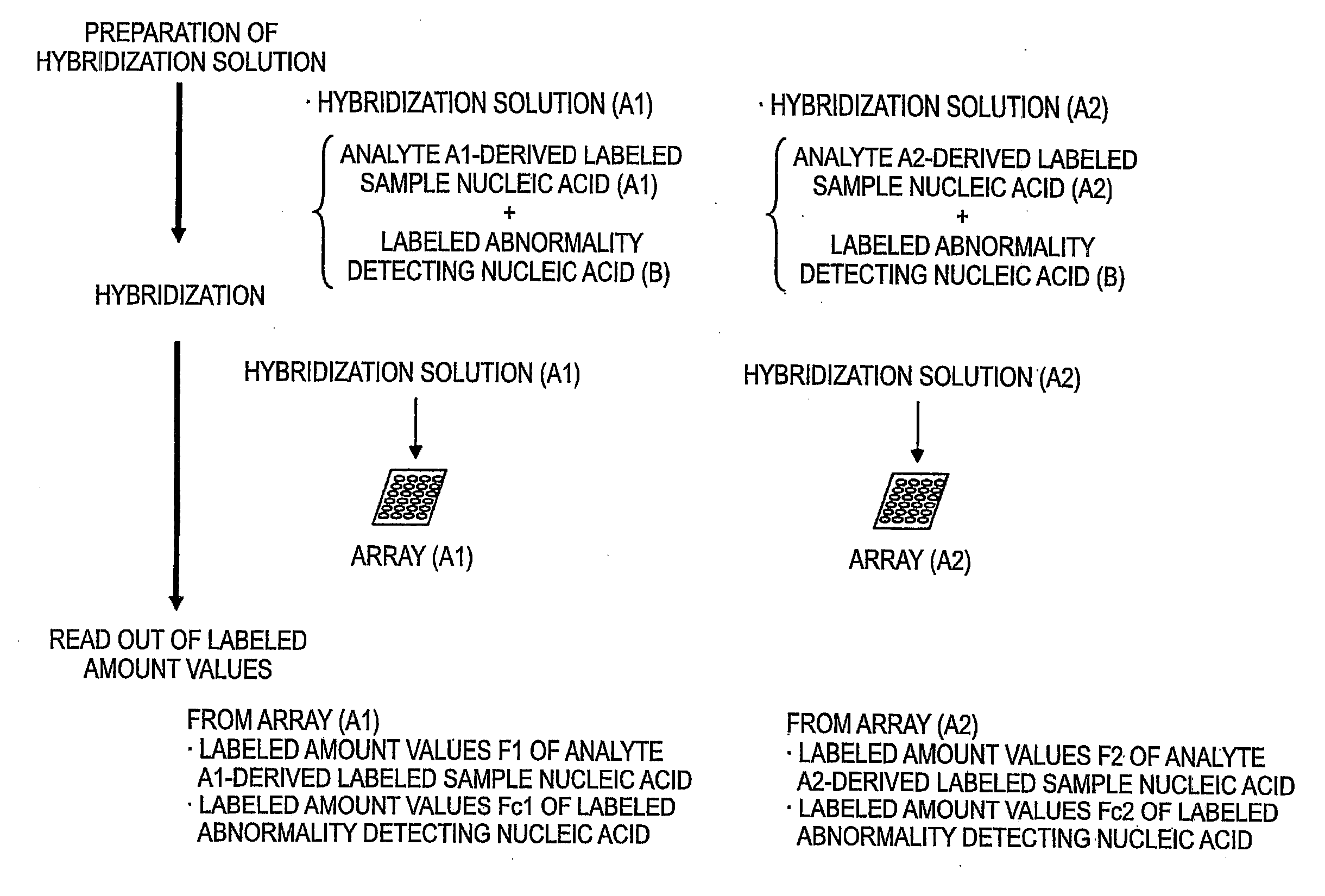

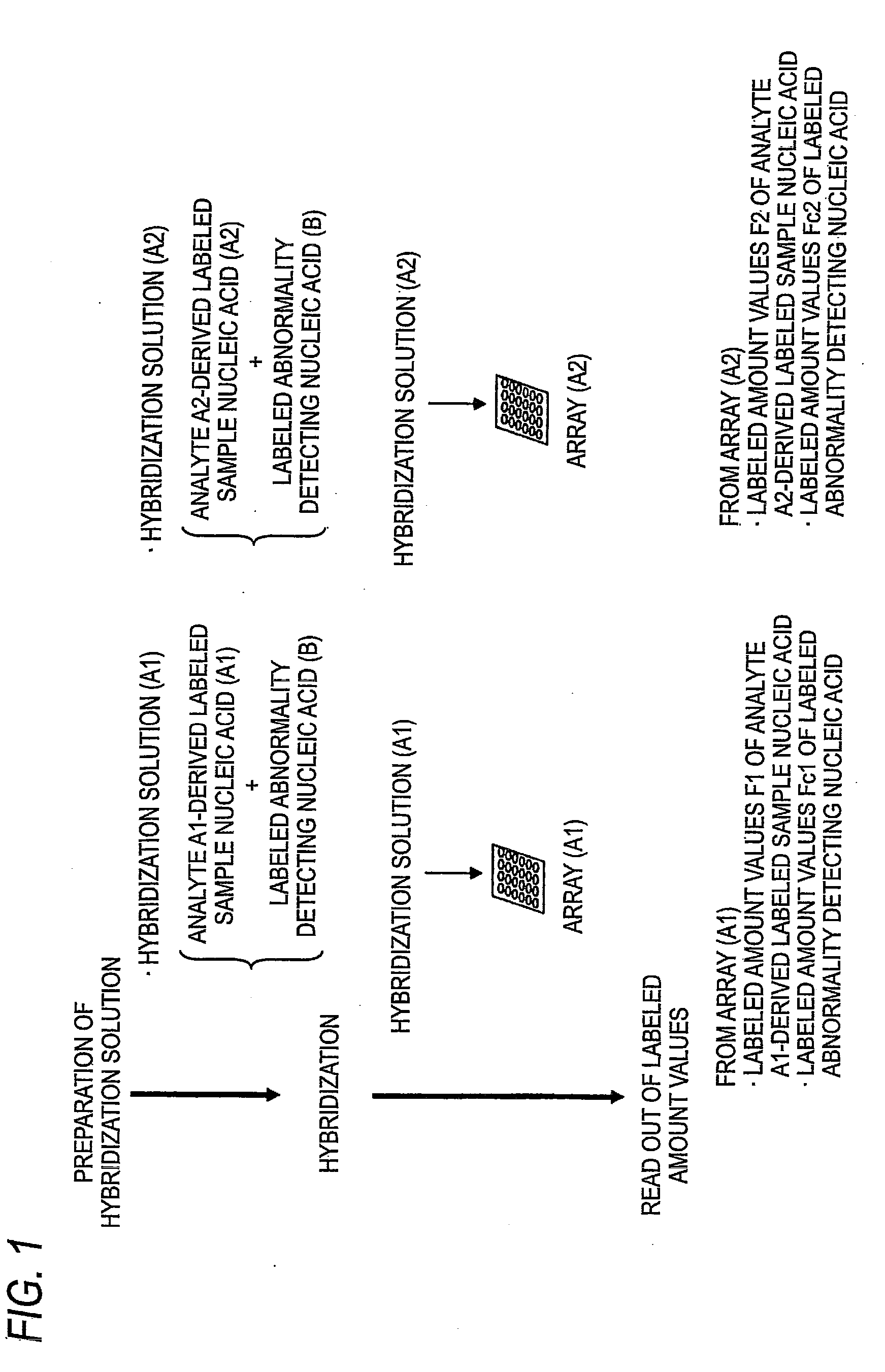

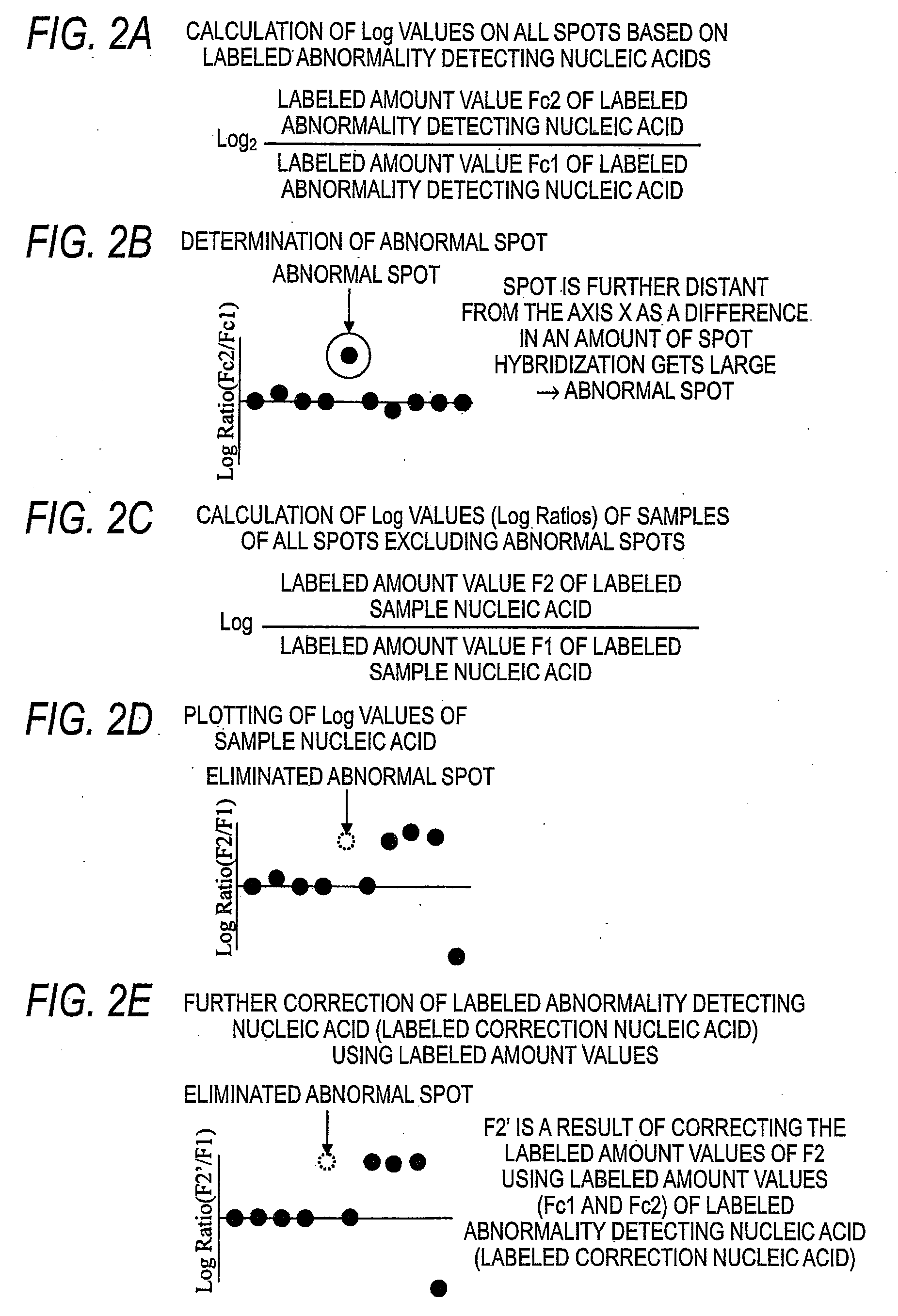

Method for detecting abnormal spots of nucleic acid microarray

InactiveUS20100304997A1Reduce variationAccurate dataNucleotide librariesMicrobiological testing/measurementAnomaly detectionBioinformatics

A method carries out a nucleic acid analysis using a nucleic acid microarray. A probe nucleic acid including a probe sequence (a′) complementary to a target sequence (a) and a sequence (b′) which is different from the probe sequence (a′) is immobilized on the nucleic acid microarray. The method includes hybridizing the nucleic acid microarray and a labeled abnormality detecting nucleic acid (B) containing a sequence (b) which can be bound to the sequence (b′), obtaining a labeled amount value (Fc1) of the labeled abnormality detecting nucleic acid (B) from a spot (X1), and determining, based on the measured labeled amount value (Fc1), as to whether or not the spot (X1) is an abnormal spot unsuitable for detecting the target nucleic acid.

Owner:FUJIFILM CORP +1

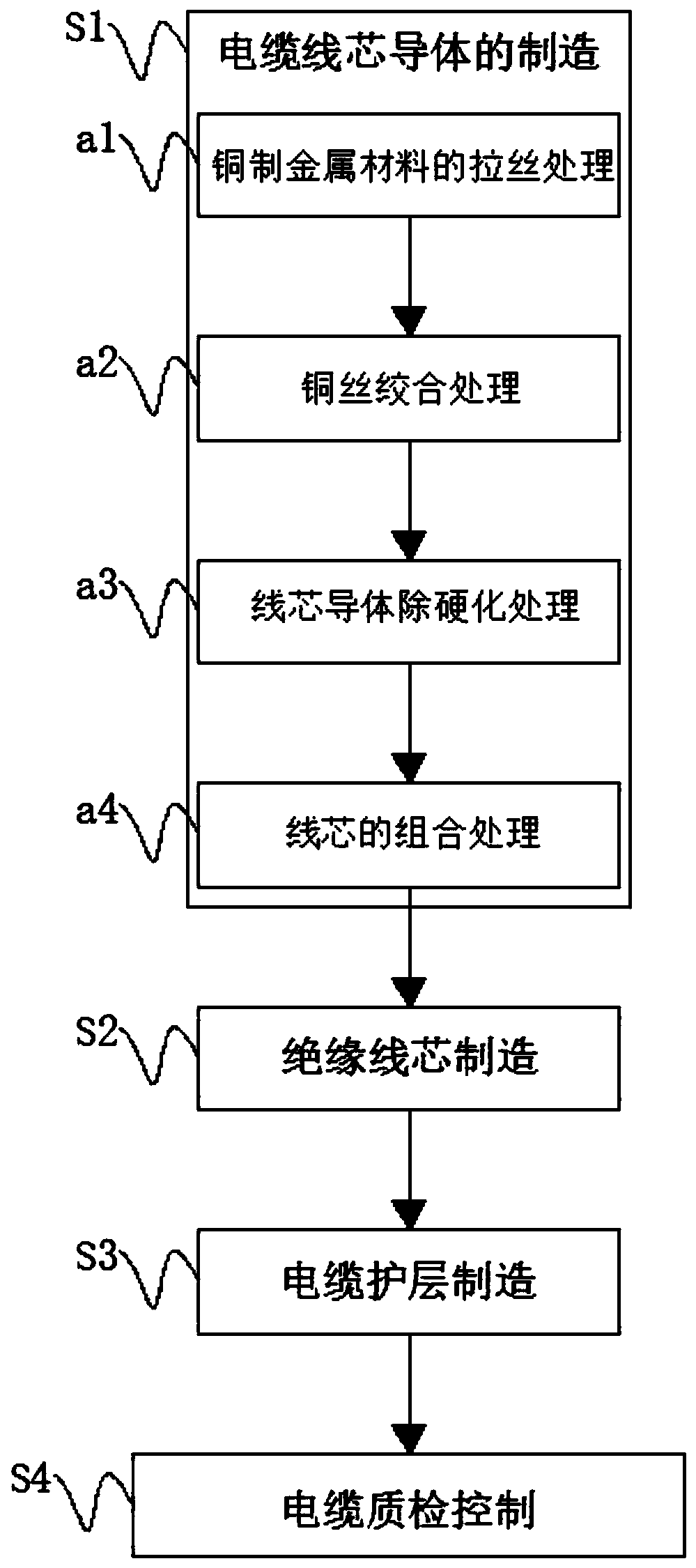

Processing method of power cable

InactiveCN110233002AEasy to useAvoid damageApparatus for heat treatmentReduction of cables/conductors sizeElectrical conductorPower cable

The invention discloses a processing method of a power cable. The processing method specifically comprises the following steps of (S1) manufacturing of a wire core conductor of a cable, namely (a1) wire drawing treatment of a copper metal material, (a2) twisting treatment of copper wires, (a3) hardening removal treatment of the wire core conductor and (a4) combination treatment of a wire core; (S2) manufacturing of an insulated wire core; (S3) manufacturing of a cable sheath; and (S4) quality control of the cable. The invention relates to the technical field of power cable processing. According to the processing method of the power cable, oven heating can be replaced through induction heating on the wire core conductor, the production staff do not need to spend a lot of time to operate andmonitor, the workload of the production staff is reduced, the production efficiency of the cable is greatly improved, the target of quickly and conveniently carrying out good hardening removal treatment on the wire core conductor of the cable is well achieved, and the targets of simplifying the production procedure of the cable and reducing the production cost are achieved, thereby greatly facilitating cable production work of the production staff.

Owner:江苏双花电线电缆有限公司

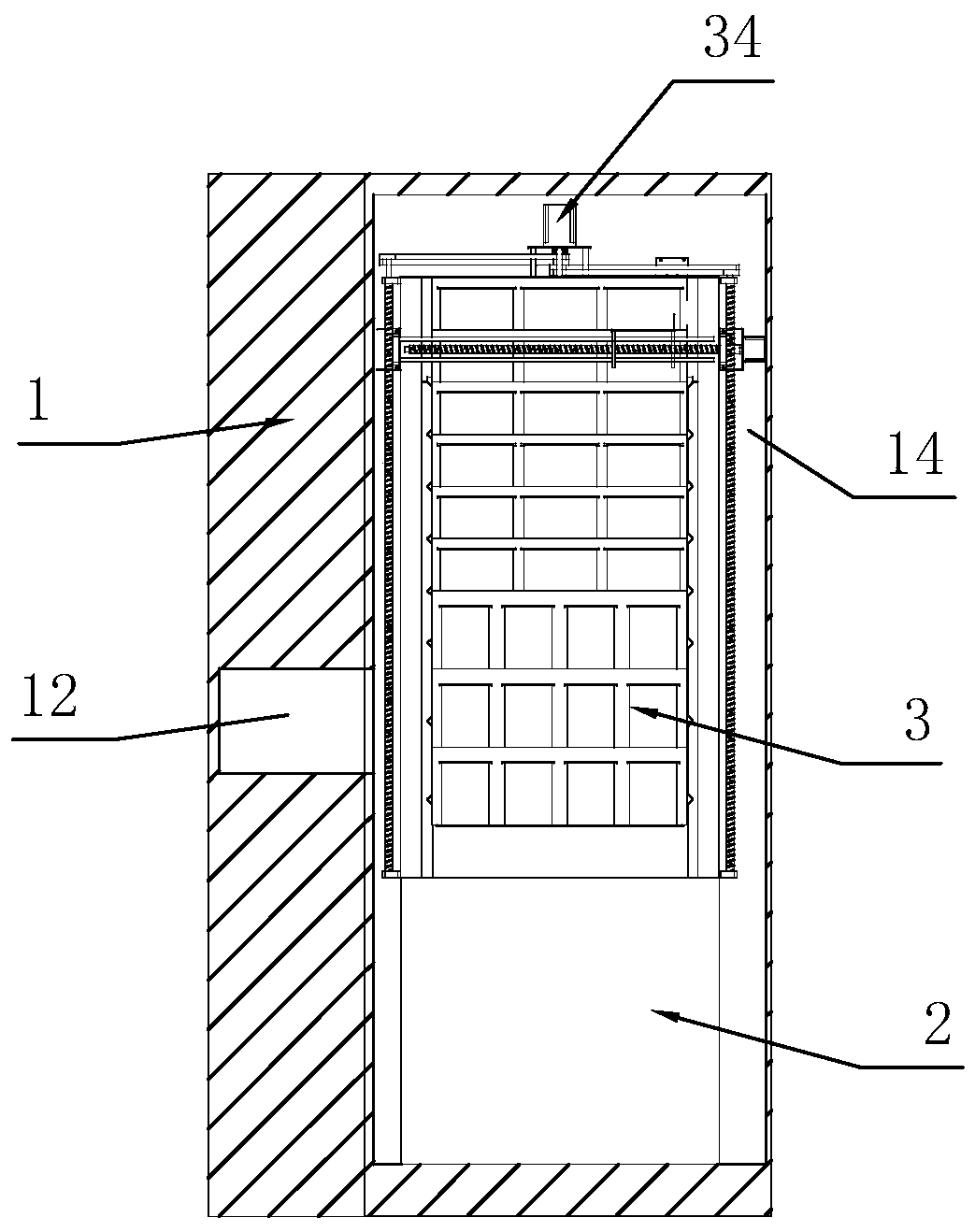

Vending machine having simple structure

PendingCN110211291AReduce the quantity requiredRealize automatic vending functionCoin-freed apparatus detailsApparatus for dispensing discrete articlesCouplingEngineering

The invention relates to a vending machine having a simple structure. The vending machine having the simple structure comprises a machine frame; a storage cavity and a pickup hole are arranged in themachine frame; several supply tracks for placing sold articles are arranged in the storage cavity; a delivery hole is formed on one end of the track direction of the supply track; a delivery mechanismfor transmitting the sold articles towards the delivery hole is arranged at the other end; the delivery mechanism comprises several push parts arranged on the various supply tracks, and a driving motor for driving the delivery part; the number of the driving motor is at least one; a first coupling part is arranged on the output shaft of the driving motor; each delivery part is separately providedwith a second coupling part; the first coupling part and the second coupling part can be in separable connection; and a switching mechanism for moving the first coupling part to any second coupling part is arranged on the machine frame. By adoption of the scheme, delivery for any supply track can be realized by adoption of the single driving motor; and thus, the vending machine having the simplestructure in the invention is low in equipment production cost, convenient to maintenance, and precise, simple and convenient to debug.

Owner:黄诚

Space man-made fertile farmland and method for producing functional organic food thereof

InactiveCN101773063AEasy to storeEasy to transportAgriculture gas emission reductionCultivating equipmentsDiseaseMedicinal herbs

The invention relates to a space man-made fertile farmland and a new method thereof for producing functional organic crops such as melon and fruit, vegetables and Chinese medicinal herbs and the like by human beings. The space man-made fertile farmland main body consists of a heavenly pillar and a reticular beam which are made of a No.200 reinforced concrete (or natural or man-made woods and various fruit trees are taken as a stand column; and the beam is made of bamboo, woods and a steel tube); a barrel bag with the length between 0.5 and 2.0m and the diameter of 0.2m which is made of high-quality plastic cloths is hung on the reticular beam through a rotary flying ring; the soil is filled with sterilized turf and plant ash; the crop is planted into a hole which is punched according to the requirements of the crops; base fertilizer and pesticide are not applied; a multifunctional ecological agriculture environment-friendly agent which is invented by the applicant is sprayed once a month, and the patent No. is 200910143893.4; required elements are instilled, the crops are irrigated through a thin pipe, the multifunctional ecological agriculture environment-friendly agent is sprayed on crops to immerse before and after mature products are harvested so as to guarantee the quality and the freshness. The method enlarges multiple times of the planted area, eliminates various agricultural diseases and toxicity of pesticide residue, produces the organic melon, fruit and vegetables which have health-care function, and increases the curative effect of the Chinese medicinal herbs, and is a new path of agricultural development.

Owner:王海文

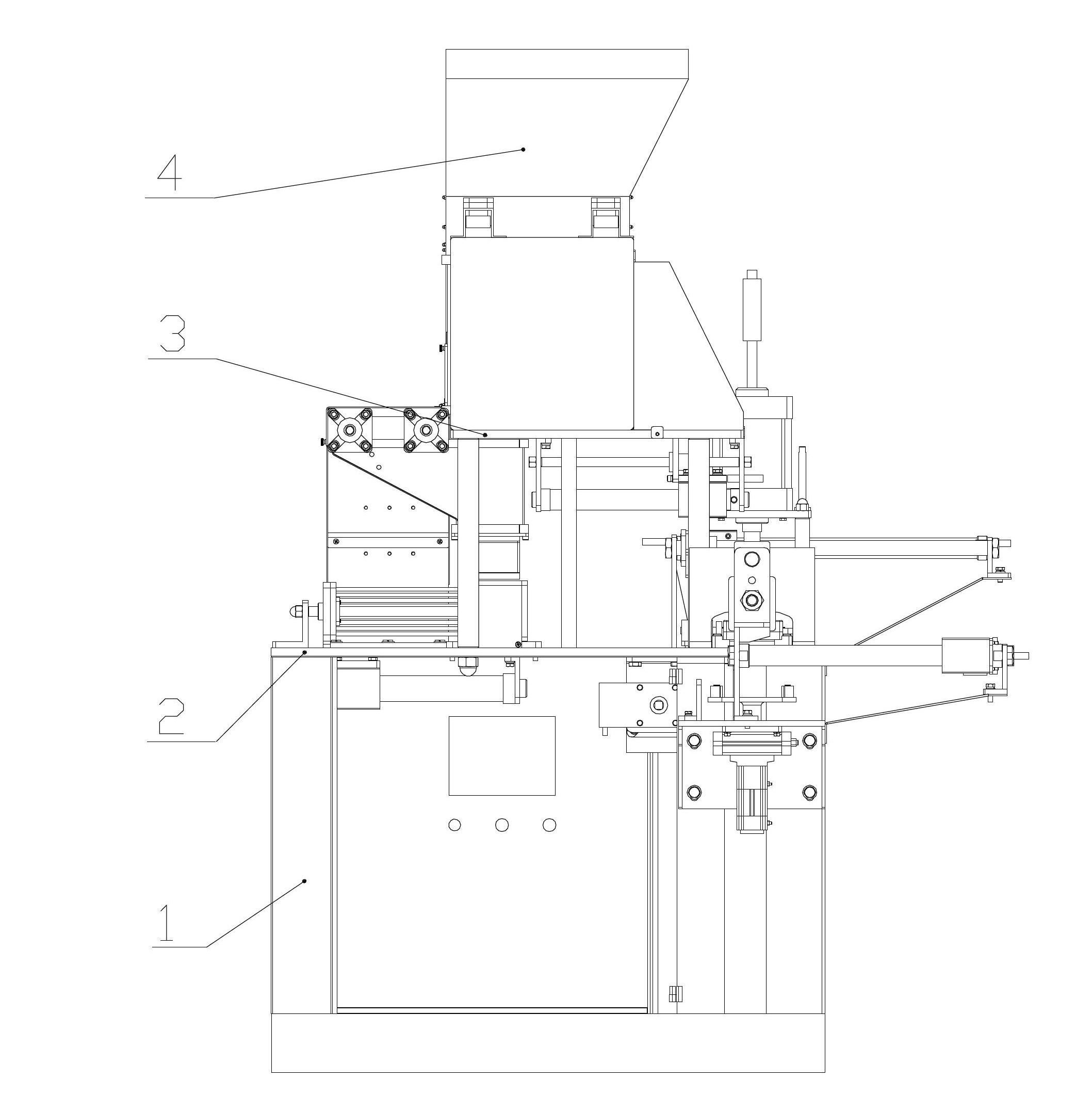

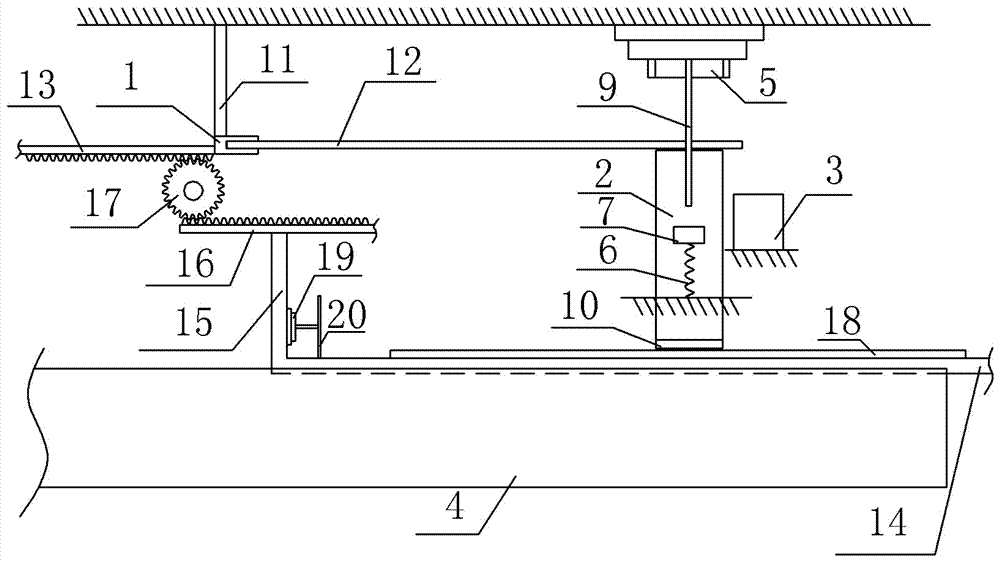

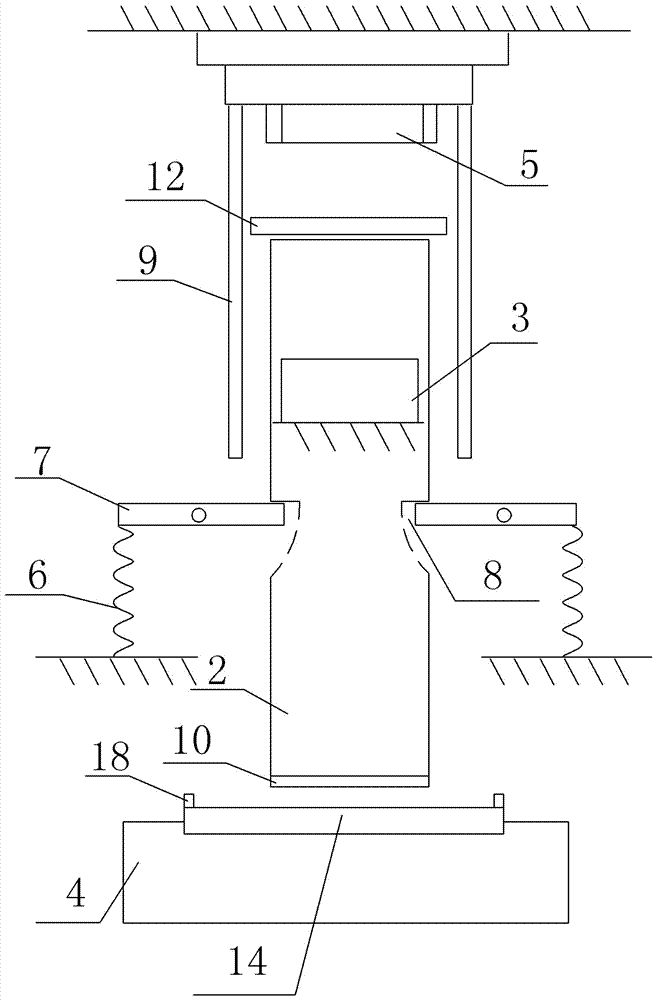

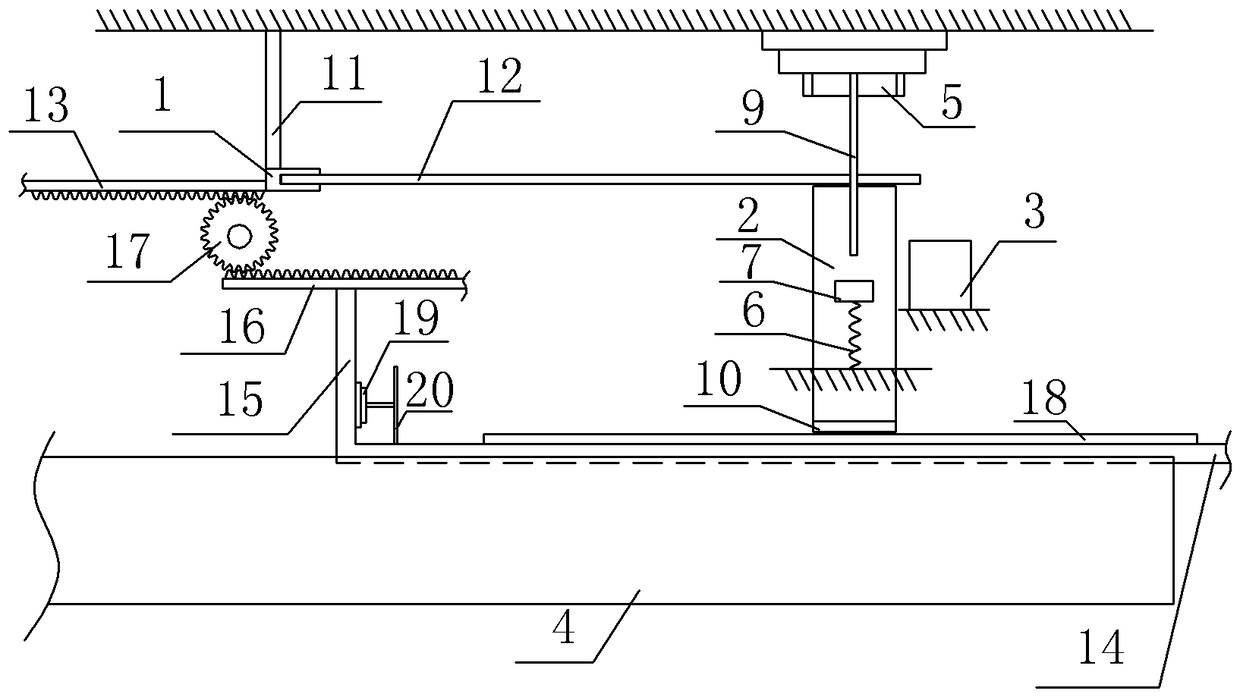

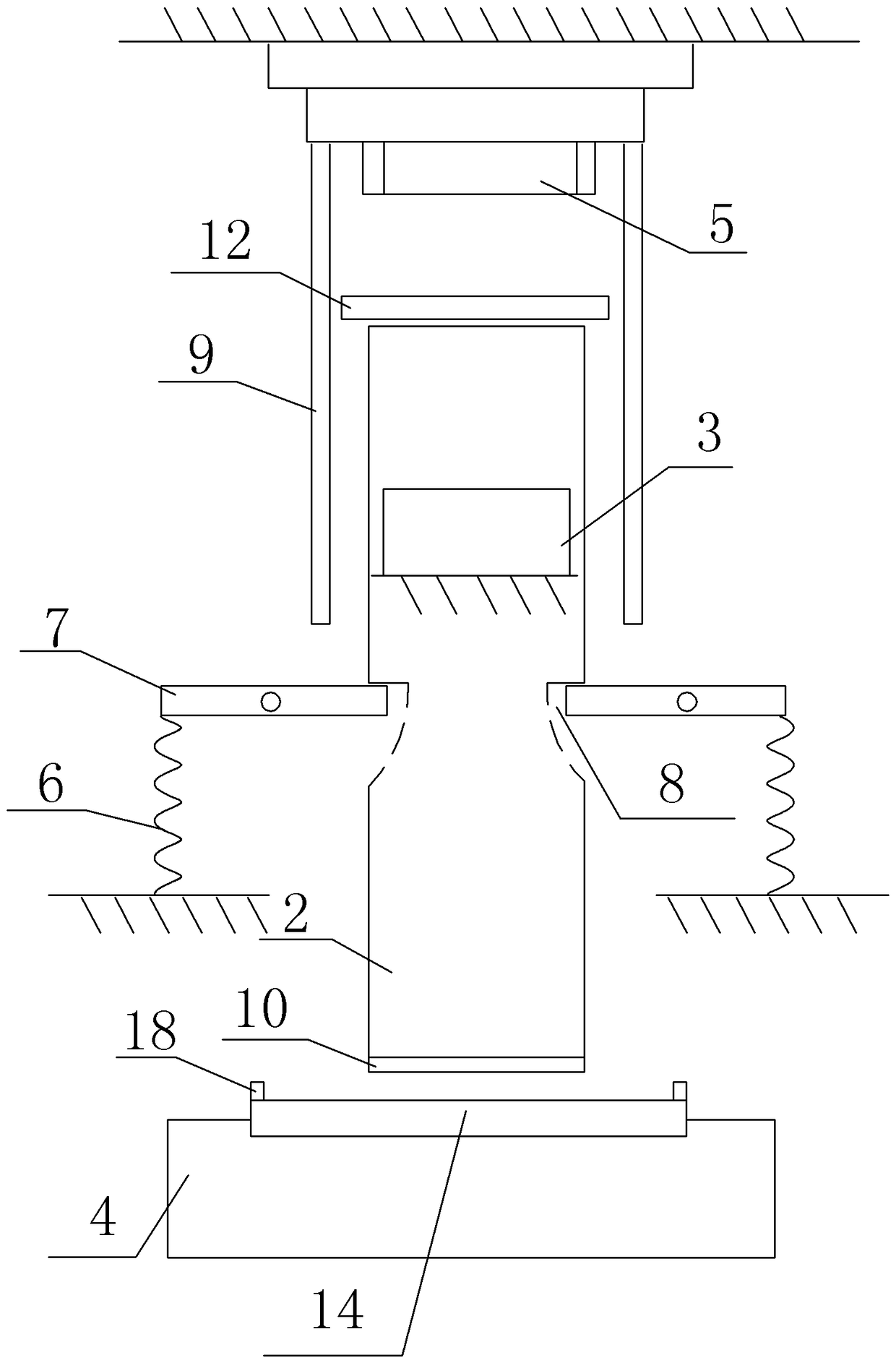

Automobile part punching equipment

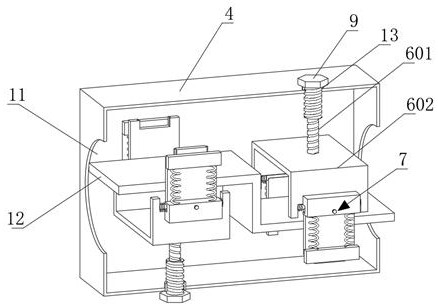

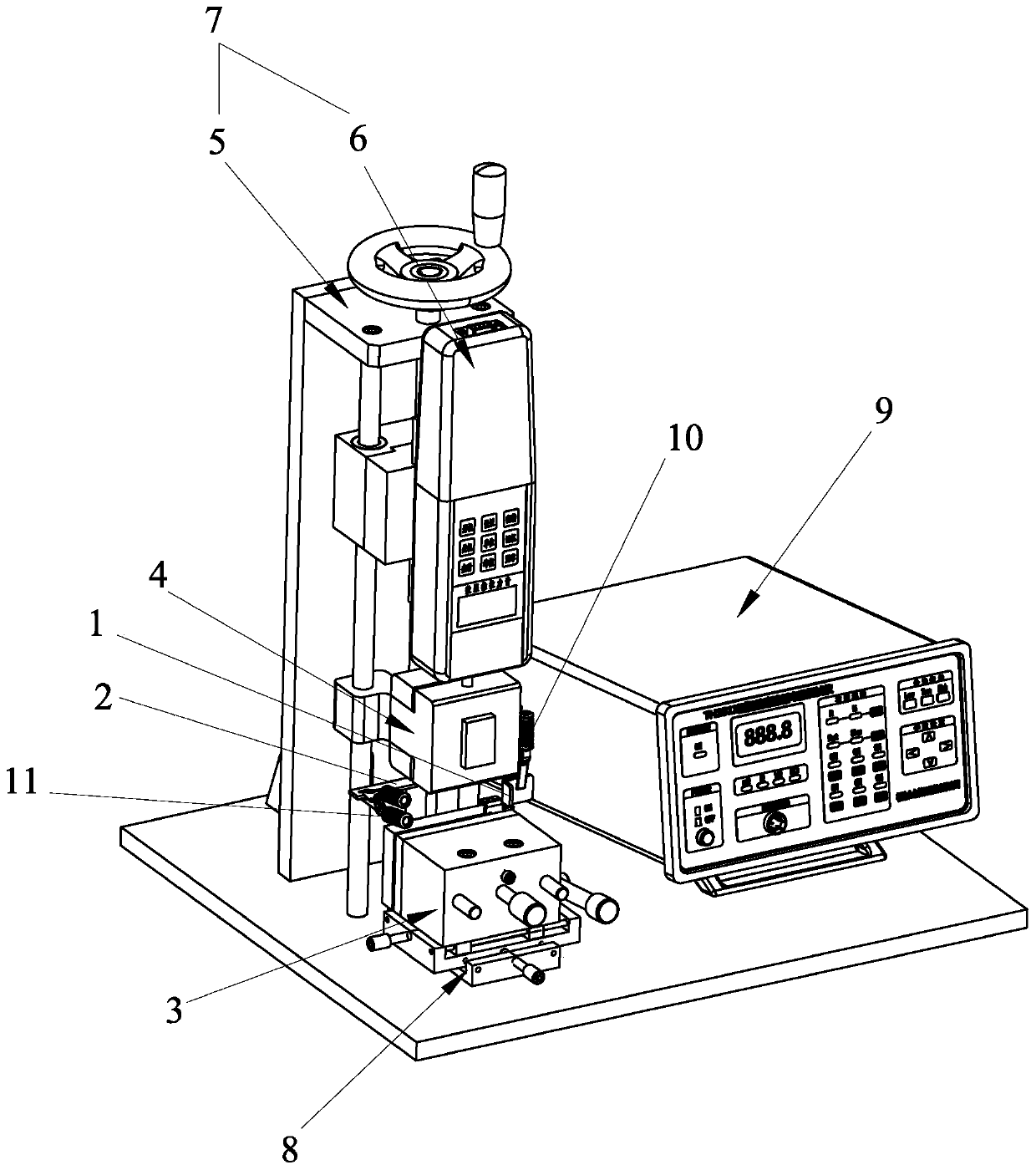

ActiveCN107363149AReduce manual labor intensityConvenient quality inspectionPerforating toolsMetal-working feeding devicesWaste materialPunch press

The invention relates to the field of part manufacturing, in particular to automobile part punching equipment. The automobile part punching equipment comprises a punch, a lower die, a servo motor, a pair of clamp pincers, a conveying plate, a waste tank and supporting mechanisms. The clamp pincers are slidably connected to a machine frame and connected with a first rack. The conveying plate is slidably connected with a base. A second rack is connected to the conveying plate. An output shaft of the servo motor is fixedly connected with a gear. The gear is engaged with the first rack and the second rack simultaneously. Each supporting mechanism comprises a tension spring and a supporting bar. The supporting bars are hinged to the machine frame. One ends of the tension springs are fixedly connected with the machine frame. The free ends of the tension springs are fixedly connected with one ends of the corresponding supporting bars. The peripheral wall of the lower die is provided with clamping grooves matched with the other ends of the supporting bars. Pressing rods are fixed to the punch. The lower ends of the pressing rods are aligned with the ends, close to the lower die, of the supporting bars. The waste tank is fixed to the machine frame and located on one side of the lower die. The servo motor and a punch press are connected through a controller in series. By means of the technical scheme, the automobile part punching equipment can automatically take parts and automatically collect waste materials.

Owner:CHONGQING YOUBO MACHINERY MFG

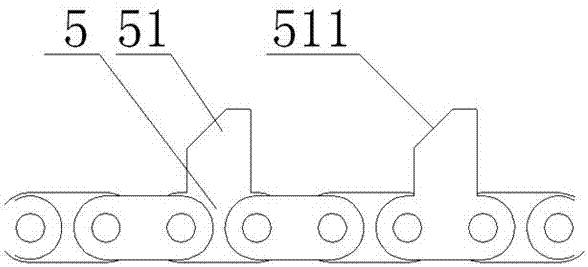

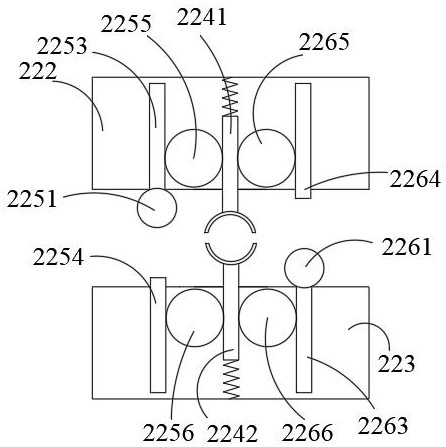

Overturning device and front face and back face overturning method of articles

The invention provides an overturning device. The overturning device comprises a first conveyor belt and a second conveyor belt which are distributed in parallel and are both used for conveying a plurality of bodies to be overturned. In the direction that the first conveyor belt forwards conveys the multiple bodies to be overturned, a baffle is arranged in front of the first conveyor belt; and when the multiple bodies to be overturned are forwards conveyed by the first conveyor belt and make contact with the baffle, the baffle enables the multiple bodies to be overturned to bend towards the second conveyor belt, the multiple bodies to be overturned are conveyed to the second conveyor belt, and the conveying direction of the second conveyor belt is opposite to the conveying direction of thefirst conveyor belt. By means of the overturning device, the multiple bodies to be overturned can be overturned by 180 degrees at a time, the distribution manner of the multiple overturned bodies isconsistent with the distribution manner of the multiple bodies to be overturned before overturning, and therefore the requirements of production occasions or other occasions are met, such as the quality testing of the front faces and back faces of the overturned bodies in the last of the production link of the bodies to be overturned.

Owner:YKK ZIPPERSHENZHEN CO LTD

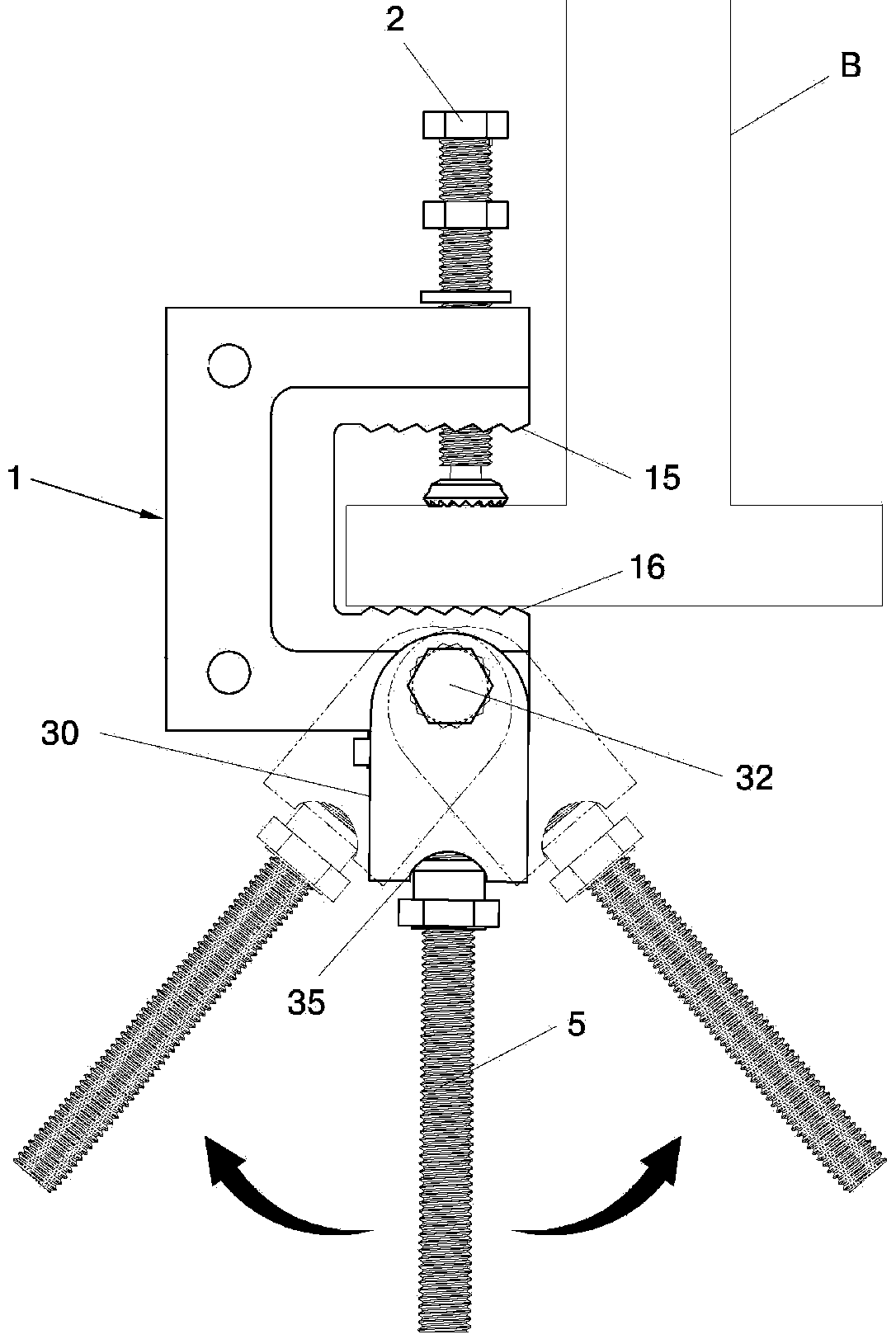

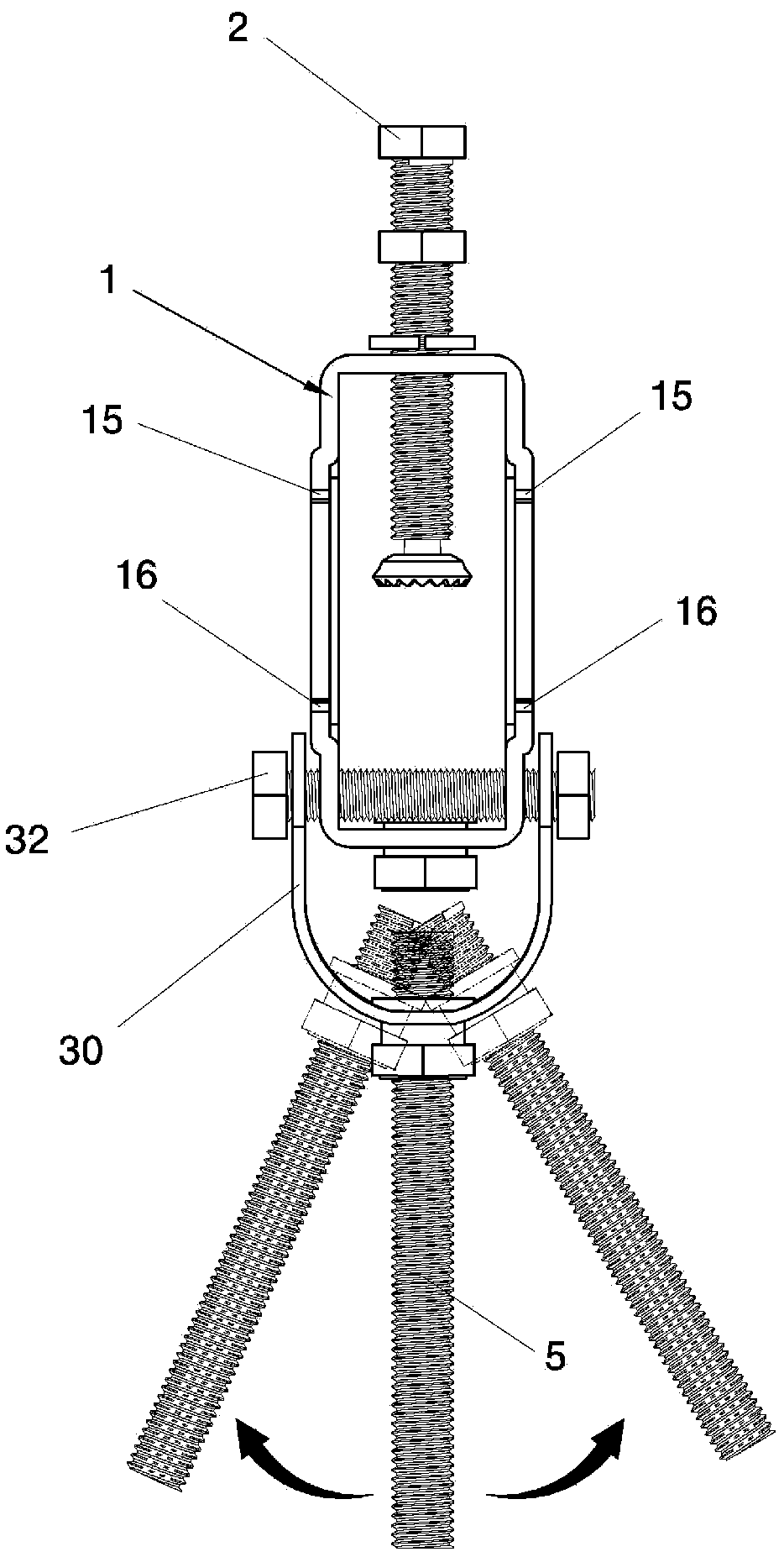

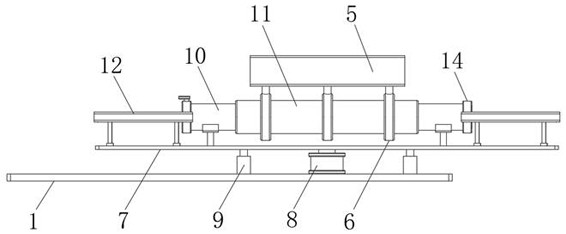

Pulley conveying and hanging mechanism

InactiveCN105366530ANot easy to bumpLess prone to angular deflectionLoad-engaging elementsEngineeringPulley

The invention discloses a hanging mechanism and particularly relates to a pulley conveying and hanging mechanism. The pulley conveying and hanging mechanism comprises a U-shaped groove, wherein two groove walls of the U-shaped groove are provided with saw-shaped teeth; an insertion hole is formed in one of the groove walls, an arc-shaped ear plate is placed into the insertion hole and is in threaded connection with a stamped nail, and the length direction of the stamped nail of the arc-shaped ear plate is consistent with the direction of a connecting line between the two groove walls; the arc-shaped ear plate is rotationally connected to the other groove wall; a bar-shaped hole is formed in the arc-shaped ear plate, and a stud is hung in the bar-shaped hole of the arc-shaped ear plate and is hung at the bar-shaped hole through a ring body; and a locating cylinder is arranged on the other groove wall of the arc-shaped ear plate, the locating cylinder of the arc-shaped ear plate is located above the stud and is internally provided with an internal thread in screw thread fit with the stud. By using the pulley conveying and hanging mechanism, the technical defect of angle regulation inconvenience or location unstability of a pulley on a conveying line in the prior art is overcome; and the pulley conveying and hanging mechanism is capable of realizing angle control and stable location.

Owner:CHONGQING ZHIRUIDE TECH

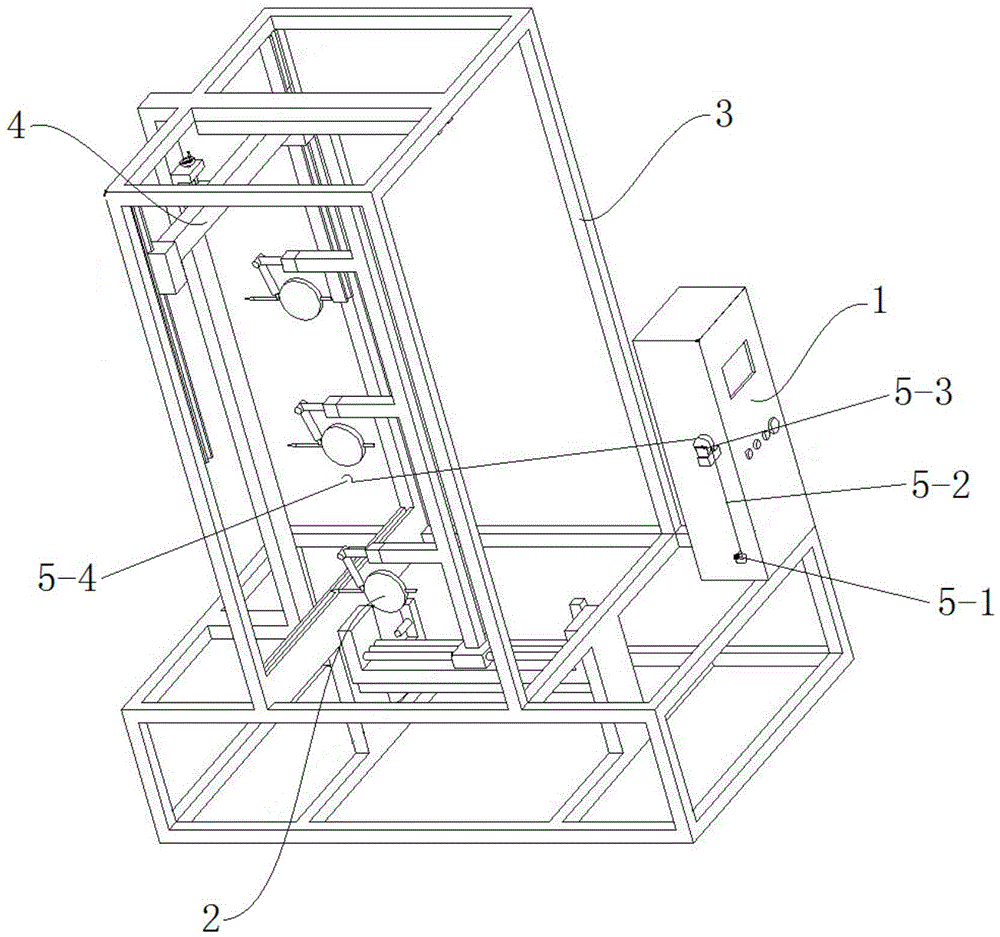

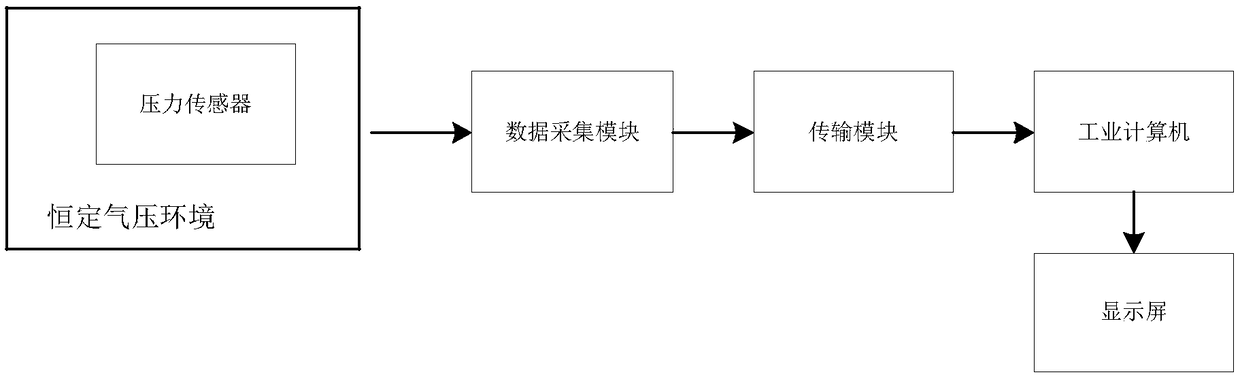

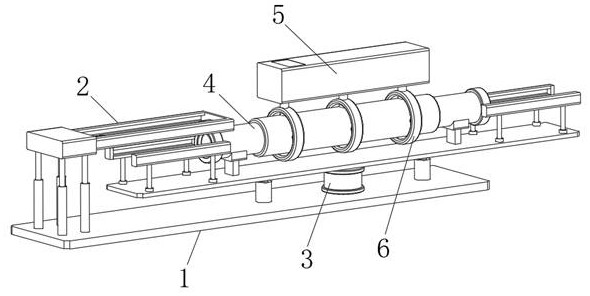

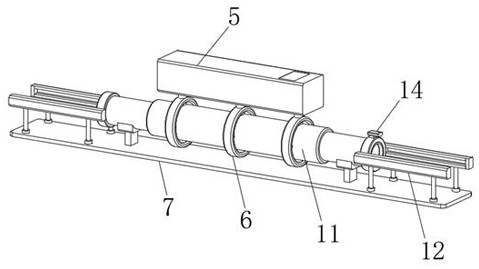

Sensor vibration experiment data acquisition system

InactiveCN108106653AConvenient quality inspectionData support is goodInstrumentsPneumatic pressureThrough transmission

The invention discloses a sensor vibration experiment data acquisition system. The system comprises a vibration test apparatus and a pressure sensor, the pressure sensor is arranged on the vibration test apparatus, the system also comprises a data acquisition module and a transmission module, the vibration test apparatus drives the sensor to vibrate according to a preset vibration mode, a pressuresensing end portion of the pressure sensor is located in a constant pressure environment, the data acquisition module acquires voltage values output by the pressure sensor in the constant pressure environment and in various vibration modes, and the voltage values are transmitted to a data analysis apparatus for analysis processing through the transmission module. The system is advantageous in that some vibration conditions of the sensor in the practical work are simulated through adjustment of the vibration modes so that the stability and the reliability of the sensor are detected, the quality inspection by manufacturers is facilitated, and data support can be provided for the improvement of products; besides, data can be checked in real time by employing a display screen so that resultsare visual and detection alarm results can be emitted in time through a computer.

Owner:WUHU GRAND VISION AUTO ELECTRONICS CO LTD

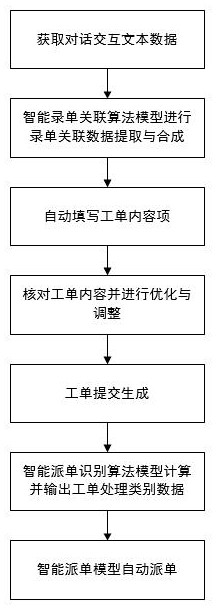

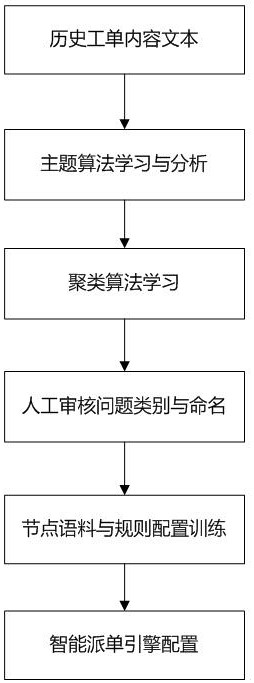

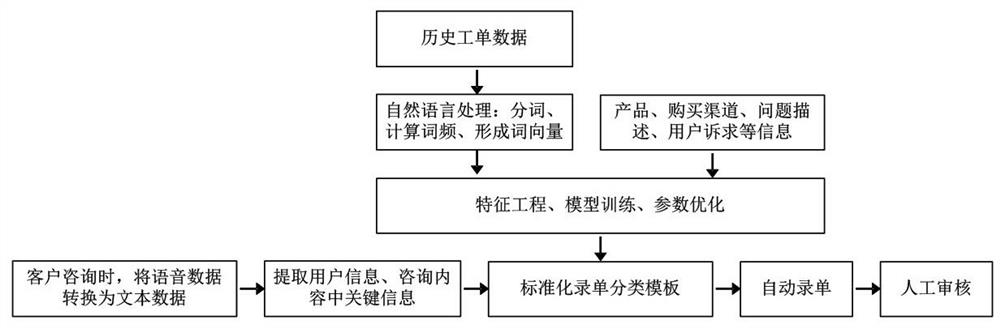

Automatic order recording and intelligent order sending method of customer service system

PendingCN114418327AImplement classification predictionStrong error capabilityCharacter and pattern recognitionNatural language data processingData ingestionRecognition algorithm

The invention discloses an automatic order recording and intelligent order sending method for a customer service system. The method comprises the following steps: step 1, obtaining dialogue interaction text data; 2, extracting and synthesizing record association data through an intelligent record association algorithm model; step 3, automatically filling in work order content items; 4, checking the content of the work order, and carrying out optimization and supplementary adjustment; 5, submitting and generating a work order; step 6, inputting the work order into the intelligent order sending identification algorithm model, and calculating and outputting work order processing category data; and 7, inputting the work order processing category data into the intelligent order dispatching model for automatic order dispatching. The method is based on a multi-algorithm model, a stable and easy-to-use data model is formed through training of a problem classification identification model, and rapid and automatic distribution of the customer service work order is effectively realized.

Owner:广西壮族自治区公众信息产业有限公司

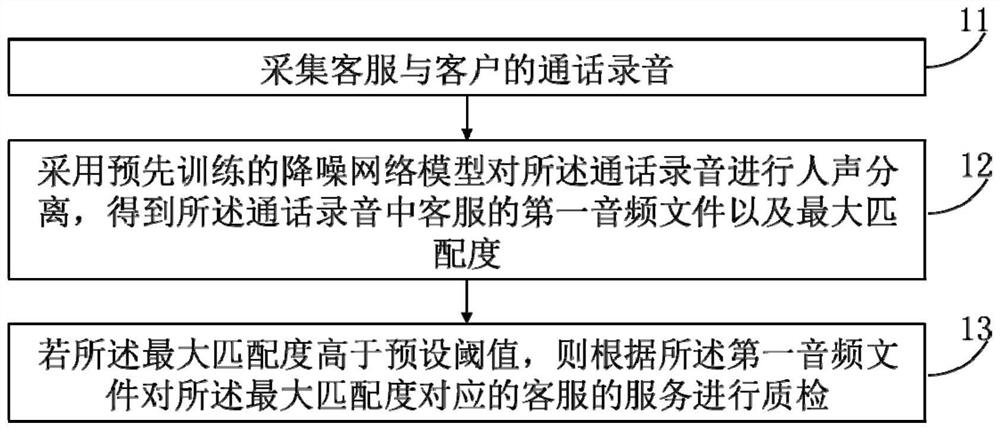

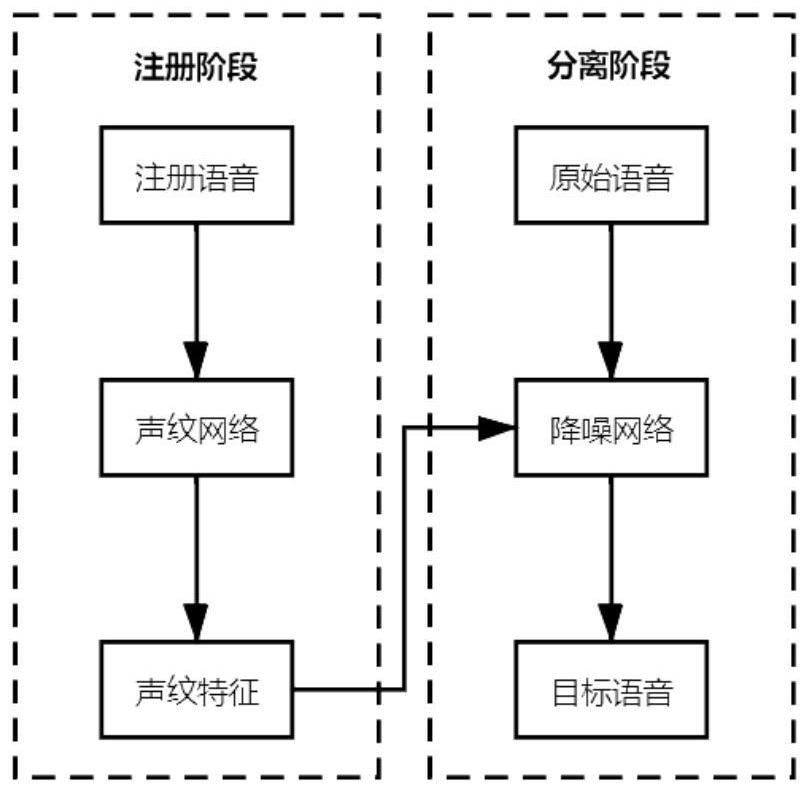

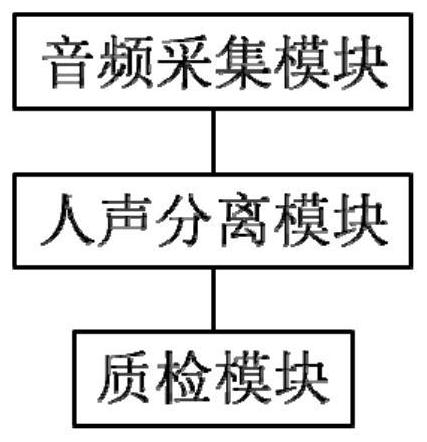

Customer service quality inspection method, system and device based on voice separation and medium

PendingCN112562644AConvenient quality inspectionFacilitate intuitive quality inspectionSpeech recognitionNetwork modelVocal sound

The invention relates to a customer service quality inspection method, system and device based on voice separation and a medium. The method comprises the steps of collecting a call record of customerservice staff and a customer; carrying out human voice separation on the call record by adopting a pre-trained noise reduction network model to obtain a first audio file of the customer service staffin the call record and a maximum matching degree; and if the matching degree is higher than a preset threshold, performing quality inspection on the service of the customer service staff correspondingto the maximum matching degree according to the first audio file. According to the invention, the human voice separation can be carried out on the call record, only the voice of the customer servicestaff needing quality inspection is reserved, the voice of customers not needing quality inspection is eliminated, the matching degree of the customer service staff is given so as to further confirm the identity of the customer service staff, and the workload of the quality inspection staff is greatly reduced.

Owner:BEIJING UNISOUND INFORMATION TECH +1

A kind of auto parts punching equipment

ActiveCN107363149BRealize automatic shiftNo need for manual pickupPerforating toolsMetal-working feeding devicesPunch pressGear wheel

Owner:CHONGQING YOUBO MACHINERY MFG

A quality detection device for door and window gauze and its application method

ActiveCN104655444BEasy to set upThe test results are close to the realStructural/machines measurementDrive motorEngineering

Owner:常州常工院技术转移有限公司

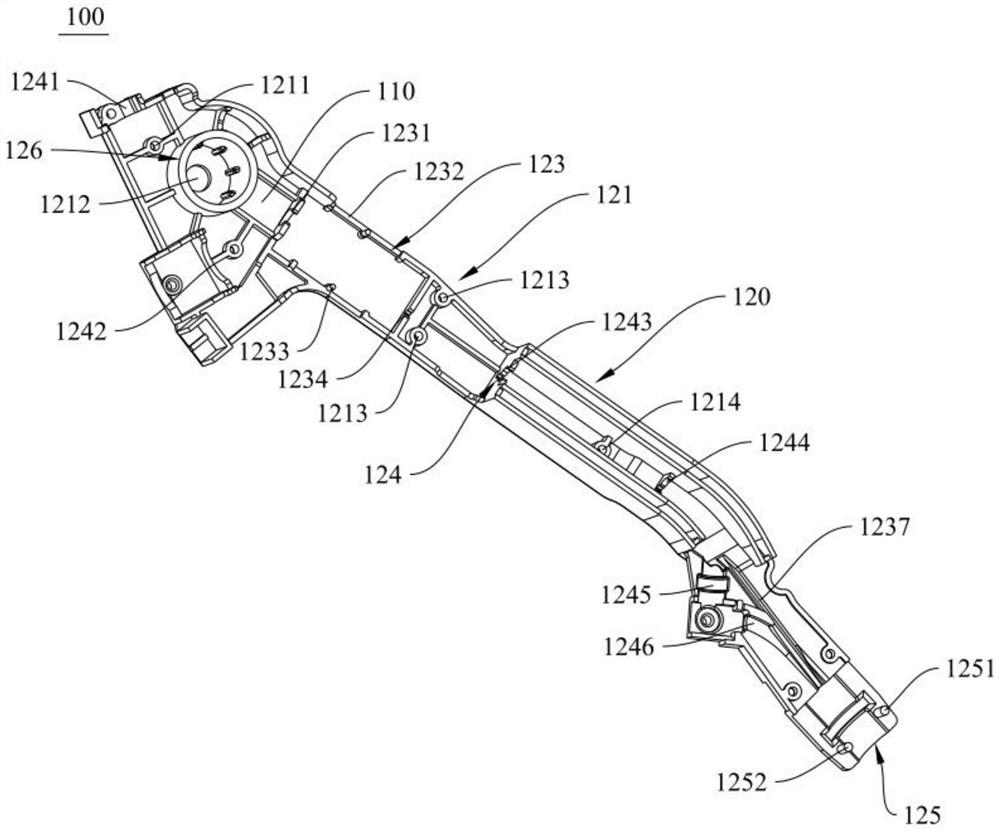

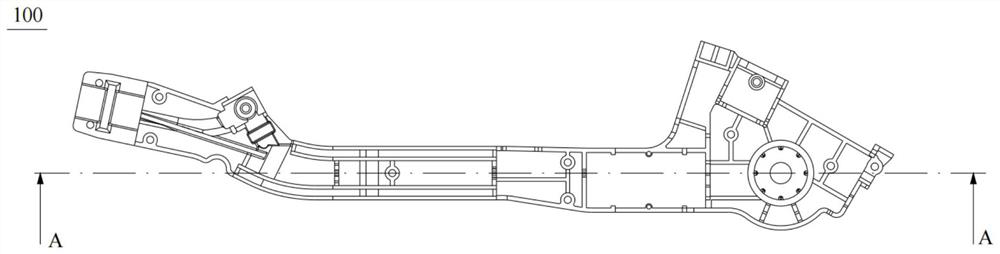

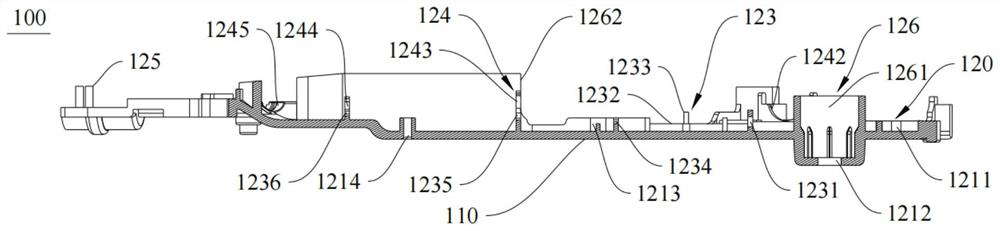

Intermediate housing, endoscope handle and method

ActiveCN114224265AEasy to placePrecise positioningSurgeryEndoscopesEngineeringMechanical engineering

The invention is applicable to the technical field of endoscopes, and provides a middle shell, an endoscope handle and a method, the middle shell comprises a middle shell body and a positioning structure, the bottom surface of the middle shell body is a plane; the positioning structure is arranged on the middle shell body; the positioning structure comprises a lower shell positioning part, and the lower shell positioning part is used for installing a lower shell. The middle shell, the endoscope handle and the method have the technical effects of being easy and efficient to assemble and suitable for automatic production.

Owner:HUNAN VATHIN MEDICAL INSTR CO LTD

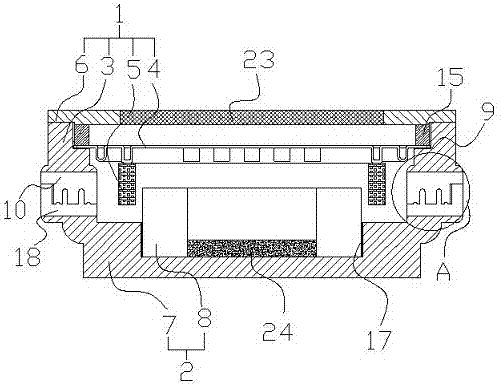

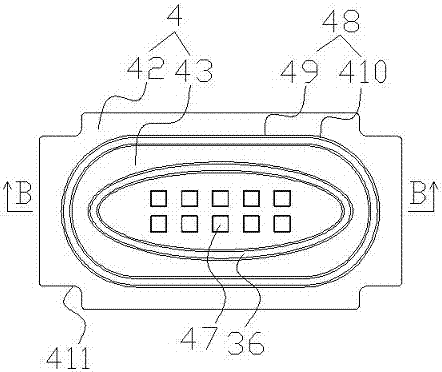

Split type high-strength receiver

PendingCN107889037AImprove rigidityIncrease the fixed areaMicrophonesElectrical transducersStructural engineeringMechanical engineering

The invention provides a split type high-strength receiver. The split type high-strength receiver comprises a receiver upper part and a receiver lower part, wherein the receiver upper part comprises an upper casing, a vibrating diaphragm, a voice coil, and a torsion cover; the receiver lower part comprises a lower casing and a magnet; the receiver upper part and the receiver lower part are fastened through threads, and are sealed through butting grooves and butting blocks; the vibrating diaphragm and a notched terrace are clamped through a connecting sleeve for fixation, and are bonded for reinforcement; and the vibrating diaphragm comprises a fixed part and a middle part, connecting areas with connecting bulges are arranged on the fixed part, a strengthening groove and strengthening bumpsare arranged in the middle part, and connecting grooves are formed between the fixed part and the middle part. The split type high-strength receiver provided by the invention has the advantages thatthe receiver is divided into the upper part and the lower part for separation production, so that the mounting is convenient, and the fault tolerance rate is increased; through the strengthening groove and the strengthening bumps, the rigidity of the vibrating diaphragm can be improved, so that the vibrating diaphragm is unlikely to be damaged; through the connecting bulges, a fixed area of the vibrating diaphragm can be effectively enlarged, so that the connecting strength is improved, and low falling possibility is achieved; and the lower end surfaces of the connecting grooves are flat, so that quality inspection is facilitated after connection of the voice coil.

Owner:奥音精密机械(镇江)有限公司

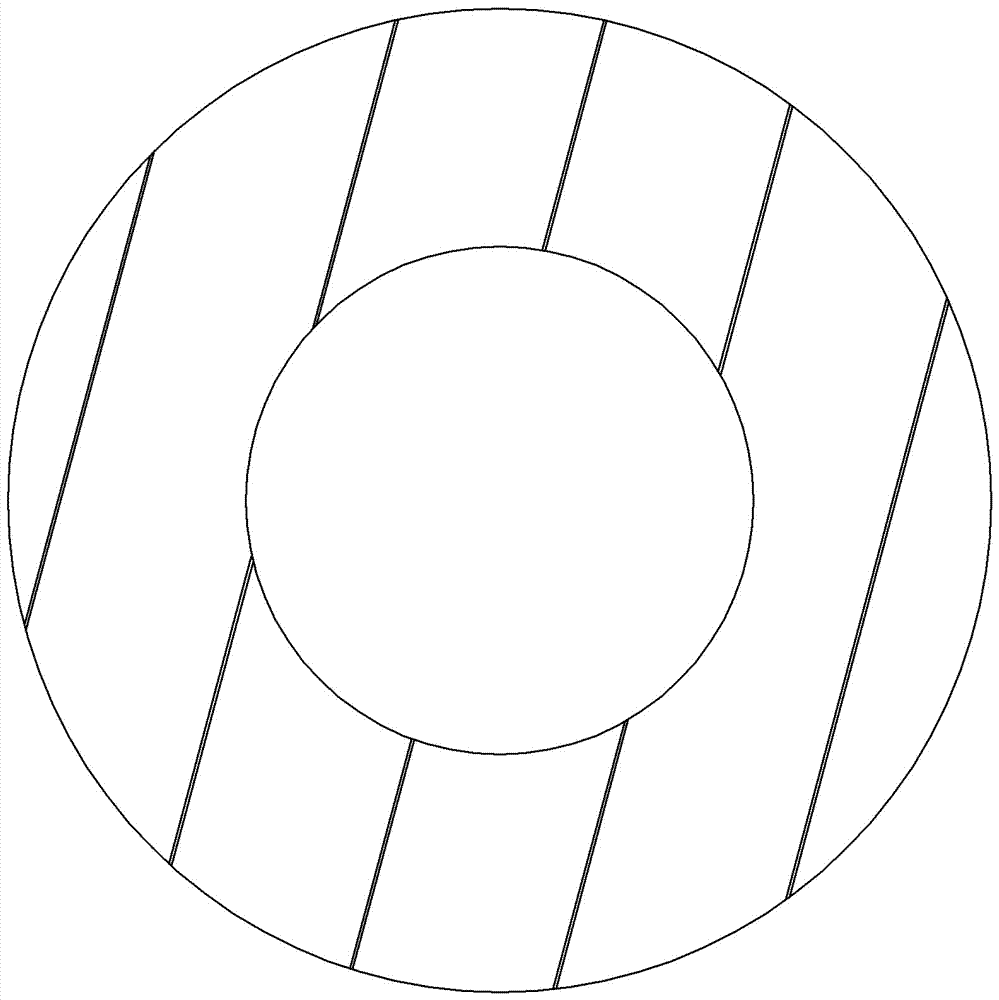

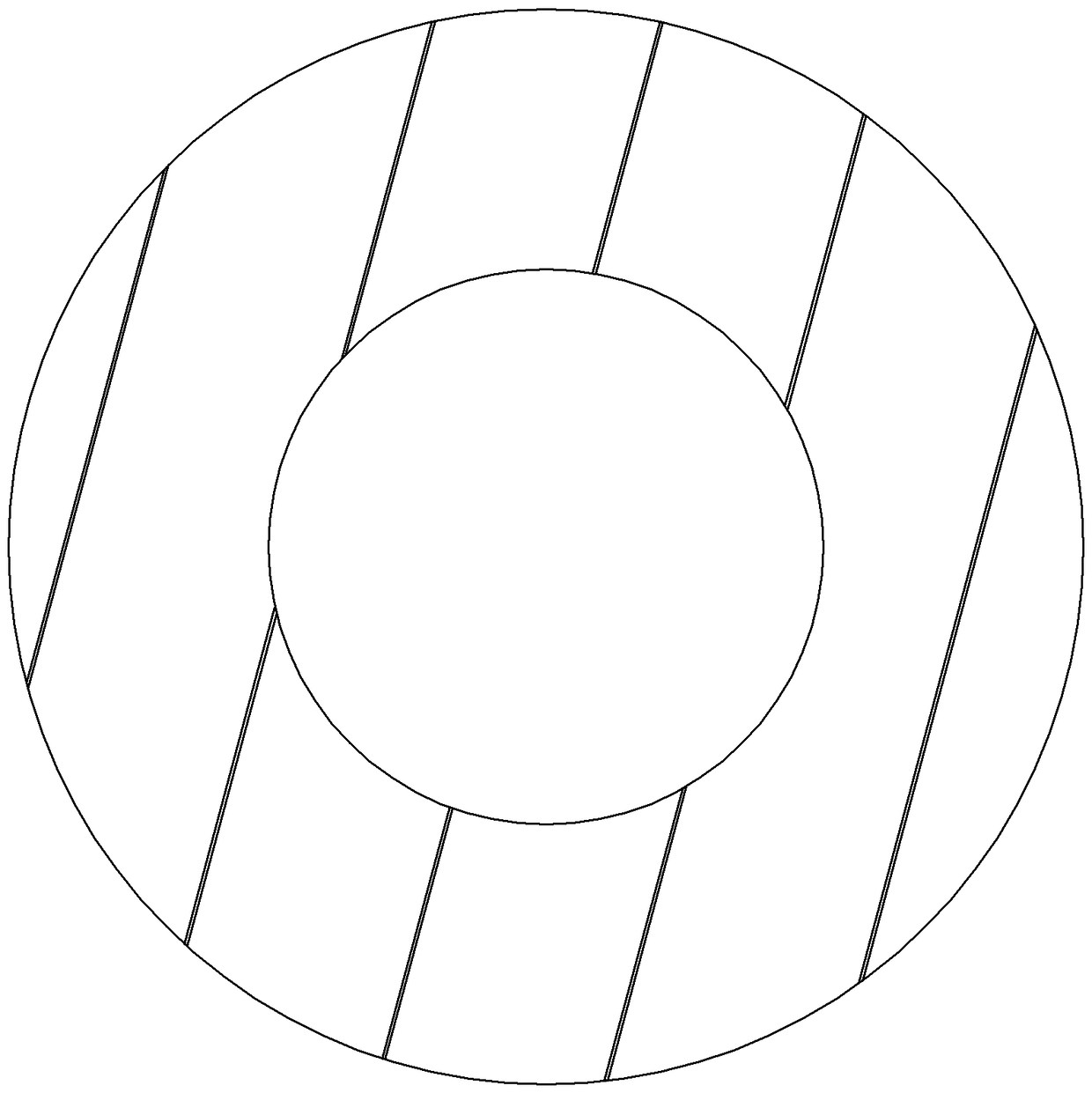

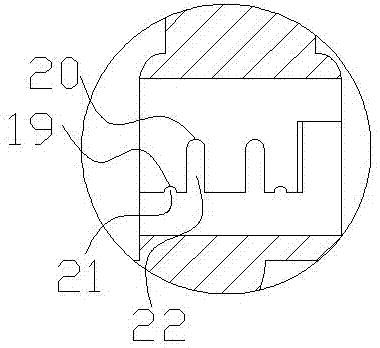

High-sensitivity telephone receiver vibrating diaphragm

PendingCN107979797AIncreased strength and rigidityIncreased sensitivityNon-planar diaphragms/conesDiaphragm mounting/tensioningUltimate tensile strengthVoice coil

The invention provides a high-sensitivity telephone receiver vibrating diaphragm which comprises a vibrating diaphragm body. The vibrating diaphragm body comprises a fixing portion, a middle portion and a connecting portion, a fixing zone with fixing protrusions is arranged on the fixing portion, an annular connecting protrusion is arranged on the connecting portion, a connecting groove is formedin the lower end surface of the connecting protrusion, a primary reinforcement portion and a secondary reinforcement portion are arranged on the connecting portion, the primary reinforcement portion comprises a plurality of fan-shaped primary reinforcement protrusions, and the secondary reinforcement portion comprises a plurality of ring-shaped secondary reinforcement protrusions. The high-sensitivity telephone receiver vibrating diaphragm has the advantages that the high-sensitivity telephone receiver vibrating diaphragm is simple in structure and low in processing difficulty; the adhesion areas can be enlarged by the fixing protrusions on the fixing portion, and the connection strength and the stability further can be improved; the connecting protrusion can be correspondingly connected with a voice coil, the position of the voice coil can be clear at a glance after being connected with the connecting protrusion, accordingly, the adhesion areas can be enlarged, and quality detection can be facilitated; the high-sensitivity telephone receiver vibrating diaphragm is provided with the multistate reinforcement portions, accordingly, the rigidity and the strength of the high-sensitivity telephone receiver vibrating diaphragm can be improved, the area of the high-sensitivity telephone receiver vibrating diaphragm can be increased, internal damping can be enlarged, and distortion canbe reduced; the sensitivity of a telephone receiver can be stabilized, and the voice quality can be guaranteed and improved.

Owner:奥音精密机械(镇江)有限公司

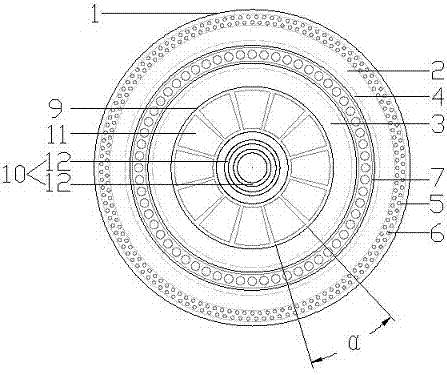

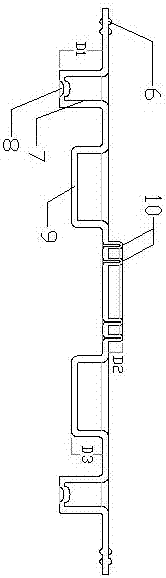

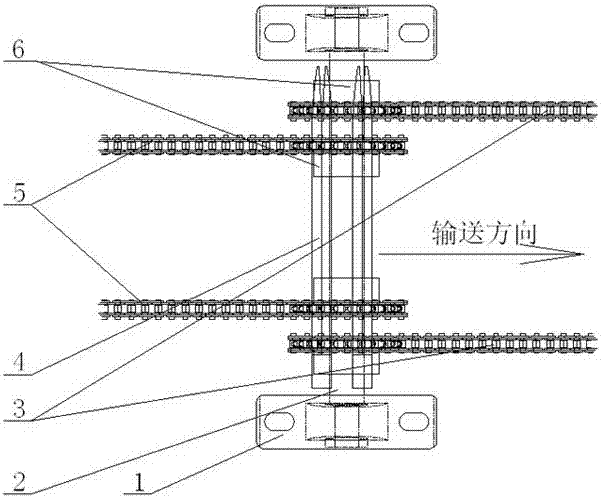

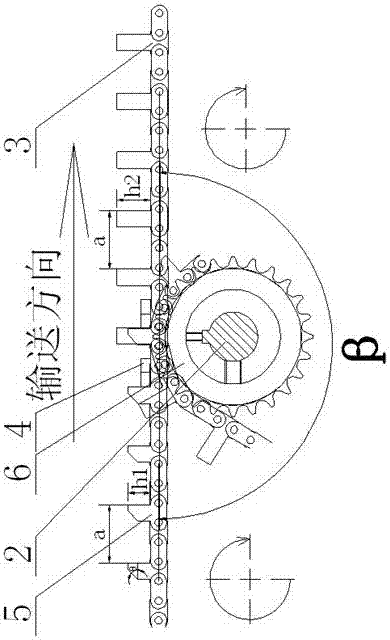

Flat chopstick turnover device

PendingCN107352249AReduce damageConvenience for continuous deliveryConveyorsConveyor partsEngineeringSprocket

The invention relates to a flat chopstick turnover device comprising a first horizontal transmission chain and a second horizontal transmission chain which are sequentially arranged in the flat chopstick transmission direction. The tail end of the first horizontal transmission chain and the front end of the second horizontal transmission chain are installed on the same rotating shaft through sprocket wheels, the operating linear velocity of the first horizontal transmission chain and the second horizontal transmission chain is identical, and two ends of the rotating shaft are fixed on a frame. The flat chopstick turnover device is simple in structure, and therefore flat chopsticks can be continuously transmitted and turned over conveniently, the flat chopsticks can be subjected to continuous quality inspection conveniently, and the manufacture cost is low.

Owner:CHANGSHA SINOTONG PPC +1

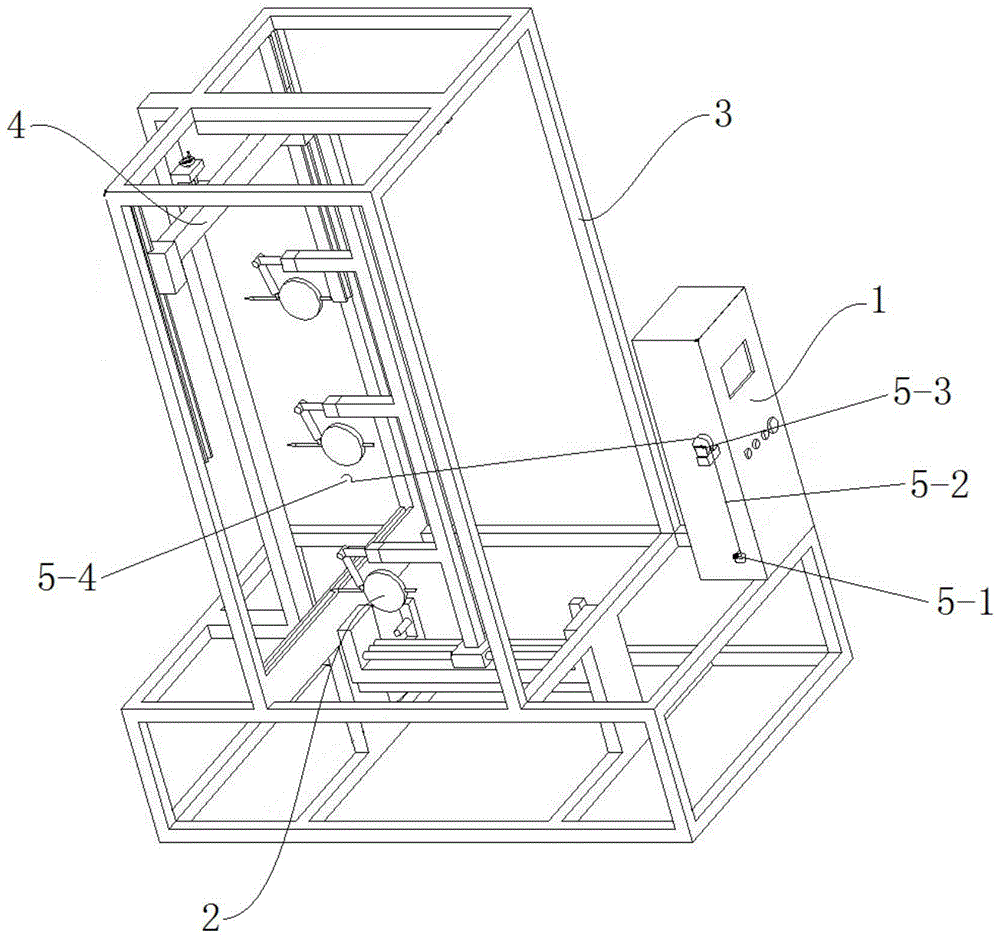

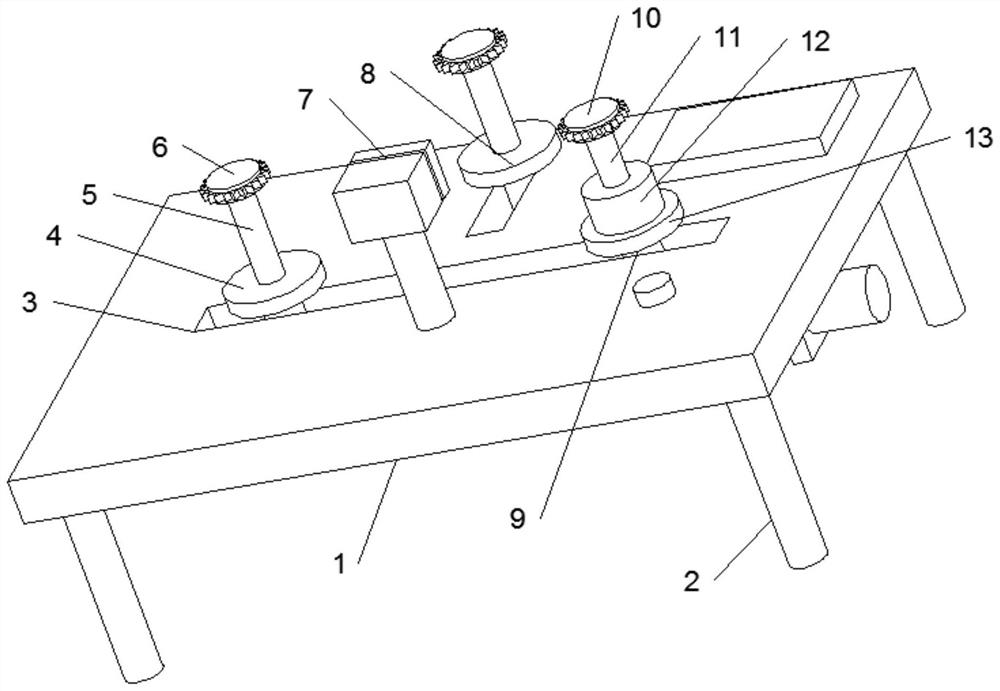

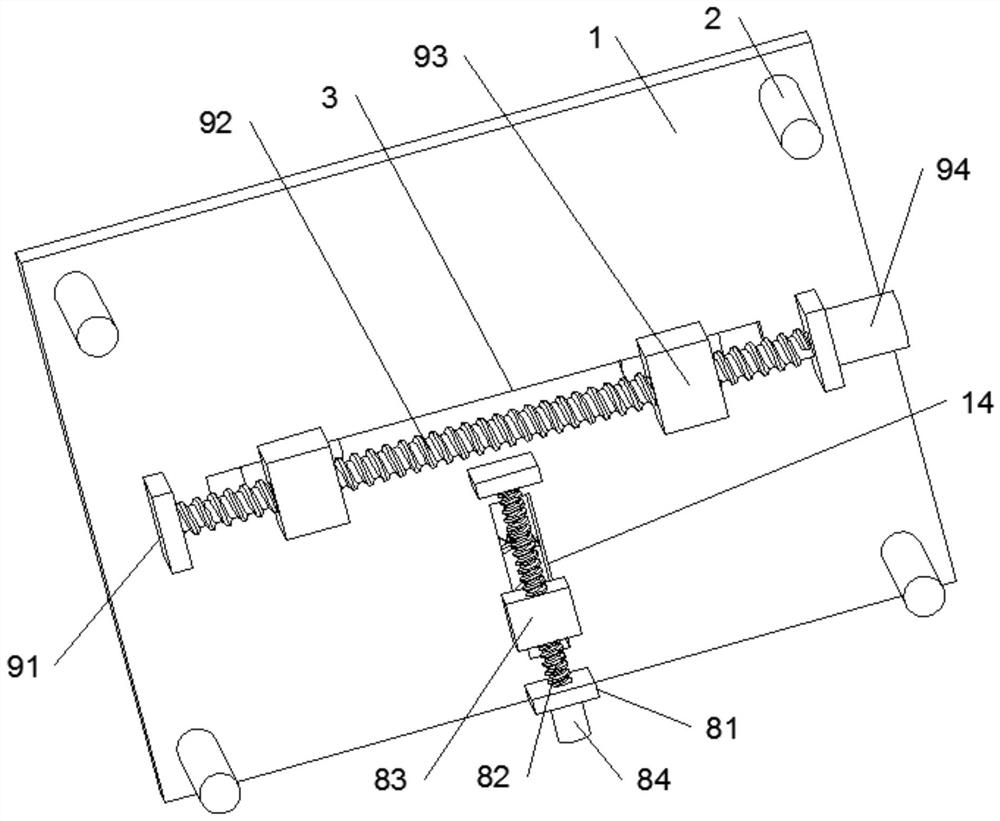

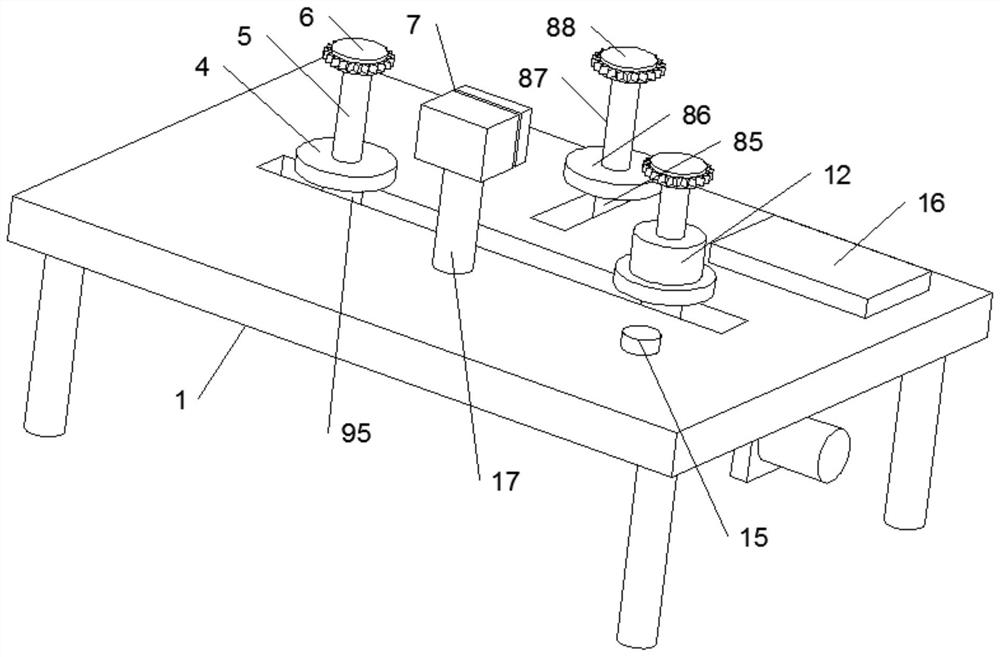

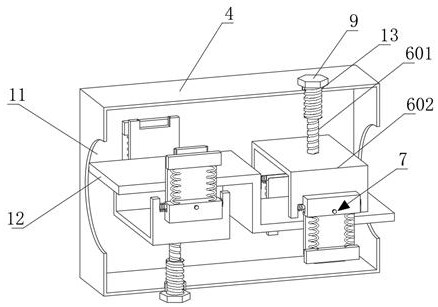

Quality inspection device in chain production and processing process

PendingCN113899546AConvenient quality inspectionEasy to useMachine part testingGearingElectric machineryEngineering

The invention discloses a quality inspection device in a chain production and machining process. The device comprises a workbench, a first through groove is transversely formed in the top of the workbench, an adjusting assembly is arranged at the bottom of the first through groove, a first mounting plate and a second mounting plate are connected to the adjusting assembly, a motor is arranged at the top of the first mounting plate, the output end of the motor is connected with a first rotating shaft, the top end of the first rotating shaft is rotationally connected with a driving chain wheel, the top of second mounting plate is connected with a second rotating shaft, and top of the second rotating shaft is rotationally connected with a driven chain wheel,a second through groove is longitudinally formed in the rear side of the top of the workbench, a tensioning assembly is arranged on the second through groove, a connecting rod is fixedly connected to the front side of the top of the workbench, and a cleaning assembly is arranged at the top end of the connecting rod. The distance between the driving chain wheel and the driven chain wheel can be adjusted through the adjusting assembly, quality inspection can be conveniently conducted on chains of different lengths; when the chains are long, the chains can be tensioned through the tensioning assembly, so that quality inspection of the chains is very convenient; and dust attached to the chains can be cleaned through the cleaning assembly.

Owner:泰兴市神力链条有限公司

New energy automobile bunch pipe convenient to dismount and mount and provided with fixing structure

InactiveCN110054040AEasy to open and closePlay a protective effectElectric/fluid circuitWater vaporNew energy

The invention discloses a new energy automobile bunch pipe convenient to dismount and mount and provided with a fixing structure. The new energy automobile bunch pipe comprises a first bunch box bodyand a wire groove. The inner wall of the first bunch box body is fixedly connected with a dampproof plate through bonding, the right end of the first bunch box body is connected with a second bunch box body through hinges and screws, the right end of the first bunch box body is fixedly connected with the hinges through screws and screw holes, a winding reel is mounted in the first bunch box body,the wire groove is mounted in the outer wall of the winding reel through bonding, and the lower end of the winding reel is fixedly connected with a rotary shaft through welding. An opening and closingstructure is formed by the first bunch box body, the hinges and the second bunch box body, a bunch box is easy and convenient to open and close, and cables in the bunch box are protected; and the dampproof plate is mounted on the inner wall of the box, the interior of the box is drier through absorption of the dampproof plate on water vapor, the safety and the reliability are achieved, and the possibility of electric leakage accidents is reduced.

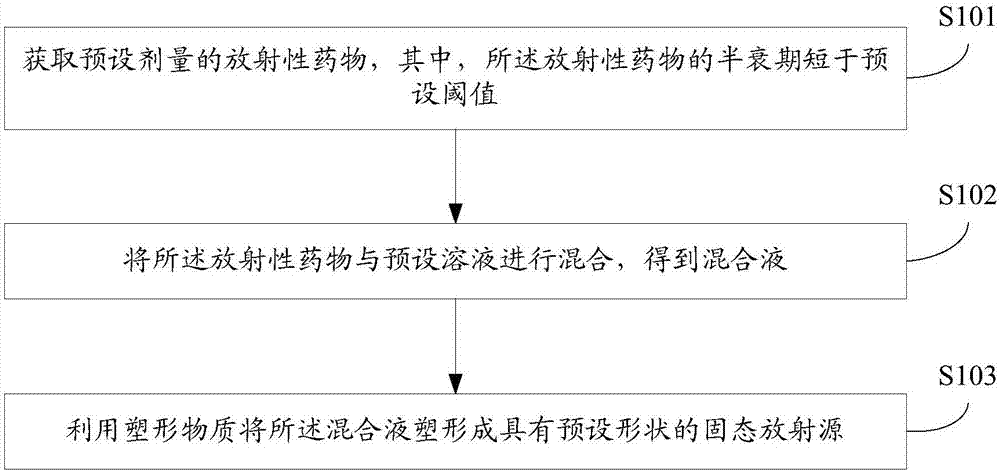

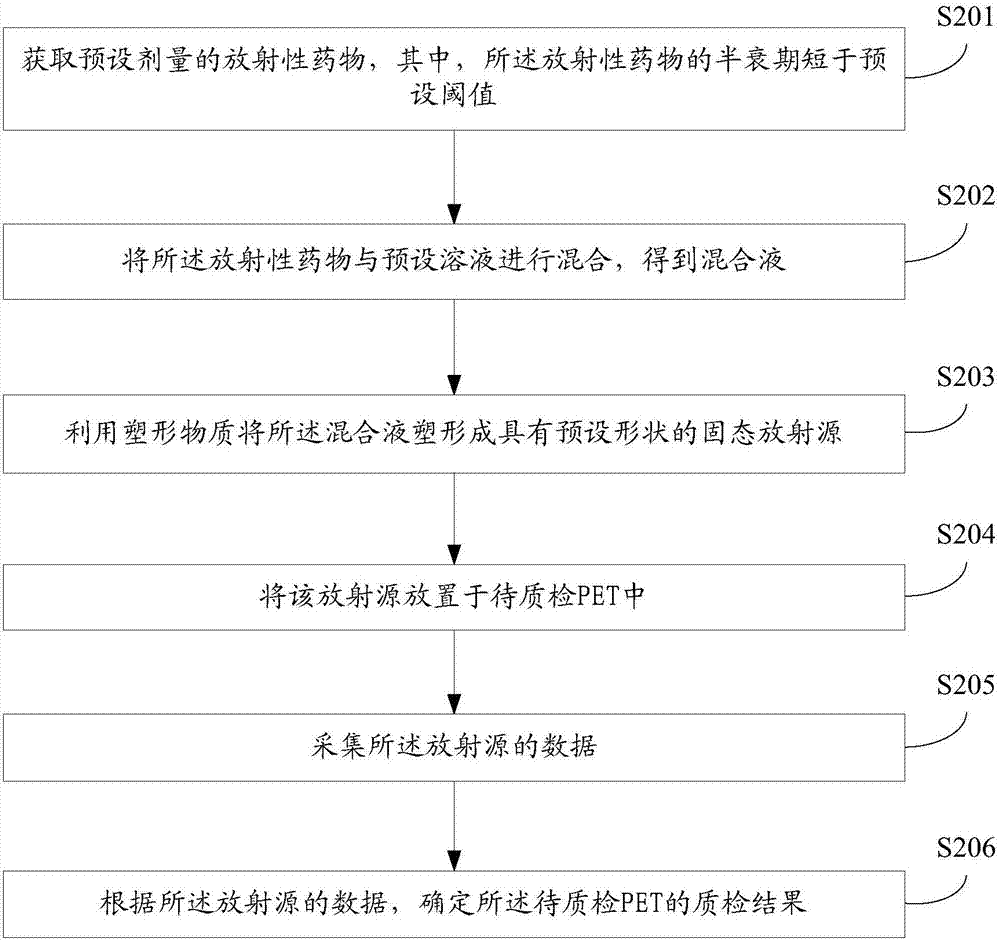

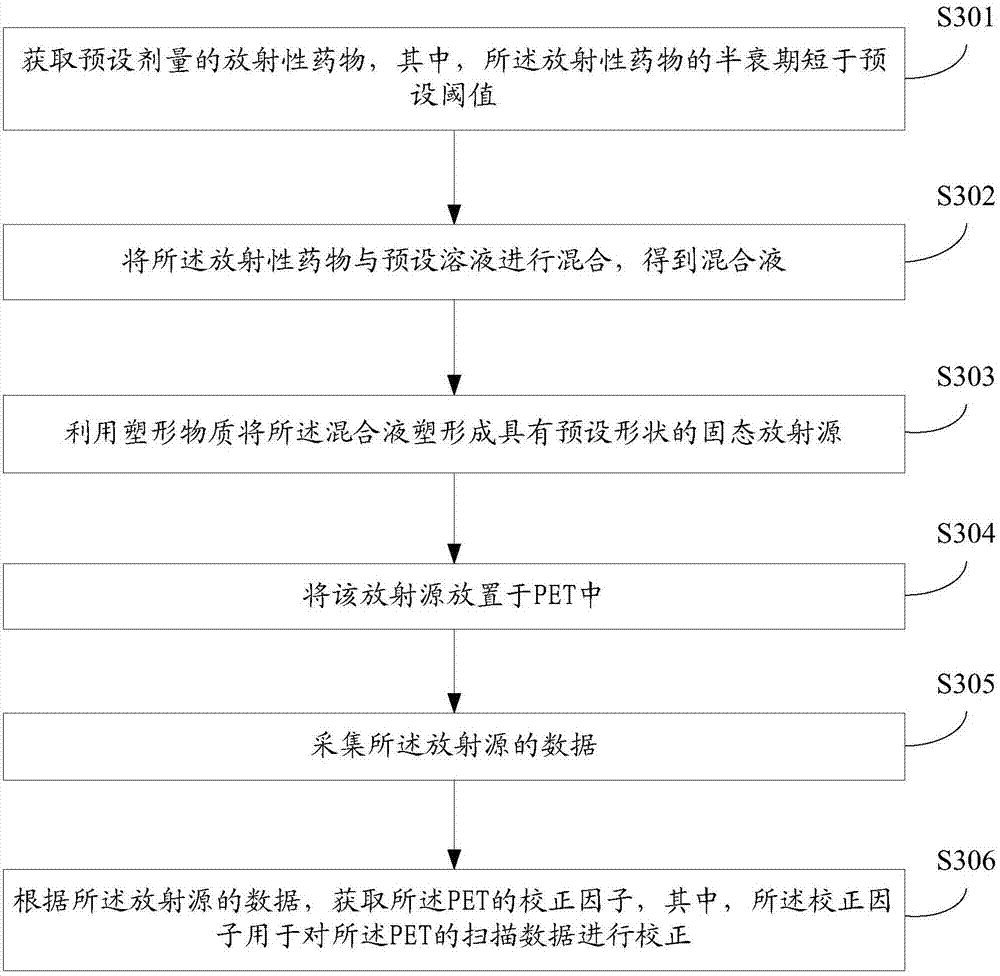

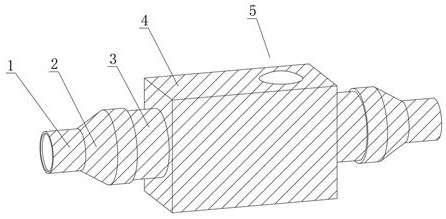

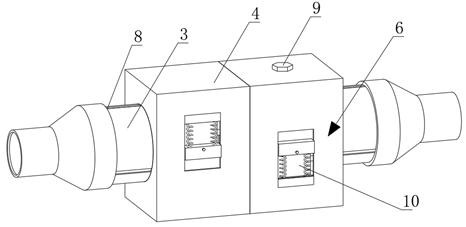

Preparation and relative preparation method of radioactive source, radioactive source and PET system

ActiveCN107374662AShort half-lifeConvenient quality inspectionRadiation diagnostics testing/calibrationComputerised tomographsRadioactive drugMedicine

The invention discloses preparation and a relative preparation method of a radioactive source, the radioactive source and a PET system. The preparation method of the radioactive source comprises the steps that a radioactive drug of a preset dosage is obtained, wherein the half-life period of the radioactive drug is shorter than a preset threshold value; the radioactive drug and a preset solution are mixed to obtain a mixed solution; a shaping substance is utilized to shape the mixed solution into a solid radioactive source in a preset shape. By means of the preparation method, the solid radioactive source is prepared, the shape of the solid radioactive source meets the requirements of a user, and the solid radioactive source is conveniently used in fields such as PET quality testing, PET correction factor acquisition and PET calibration.

Owner:SHENYANG INTELLIGENT NEUCLEAR MEDICAL TECH CO LTD

A cable connection mechanism for a data storage cabinet

ActiveCN113612041BOptimize workflowAvoid injury hazardElectric connection structural associationsCable junctionsCopper wireStructural engineering

The present invention relates to the technical field of cable connection, in particular to a cable connection mechanism for data storage cabinets, including a connection housing, two ends of the connection housing are provided with guide wire through holes, the connection housing Both ends are connected with fixing sleeves, and both ends of the two fixing sleeves are equipped with cable fixing sleeves, and the cable fixing sleeves are fixedly connected with wiring sleeves, and the connecting housing, fixing sleeve , the cable fixing sleeve and the wiring sleeve wrap the thermoplastic pipe on the surface after the cable is connected, the inside of the connecting shell is fixedly connected with a contact element, and the two first limit bolts are arranged in reverse mirror image, The invention enables the copper wire to be firmly fixed on the contact element, replaces the traditional work process of winding the copper wire on the contact element, simplifies the cable connection process, reduces labor input, and avoids the hidden danger of worker injury At the same time, the connection efficiency between the cable and the contact element is improved.

Owner:西安特茂电子科技有限公司

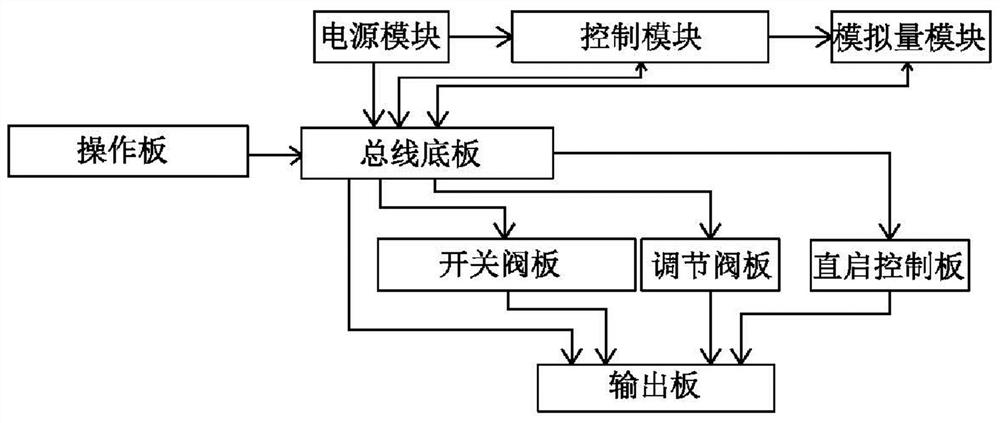

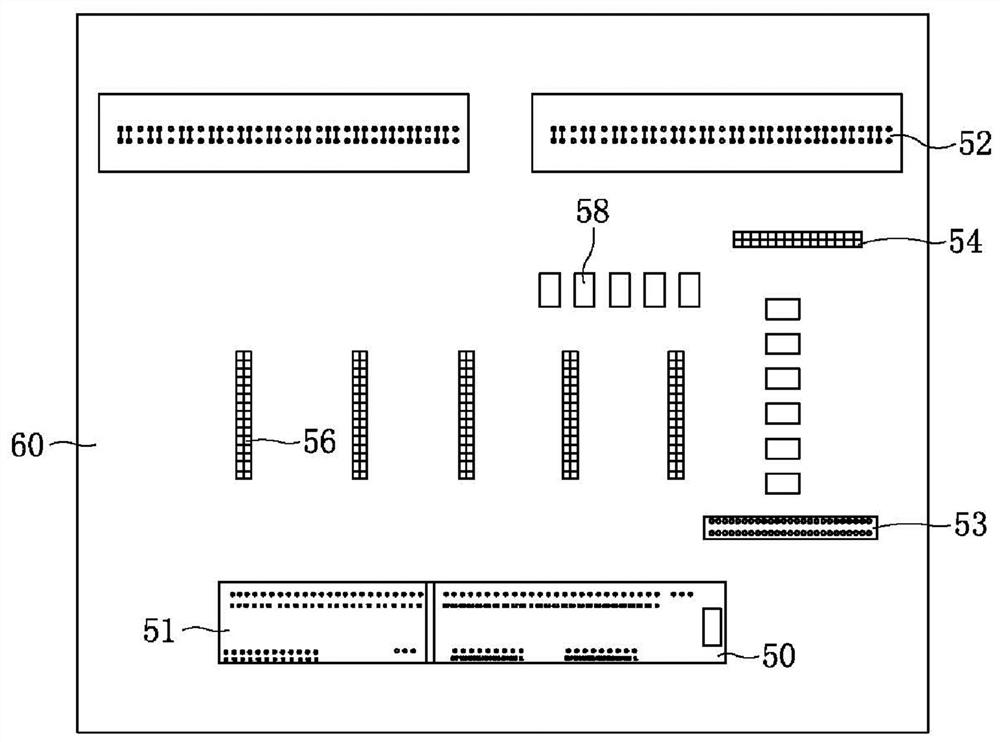

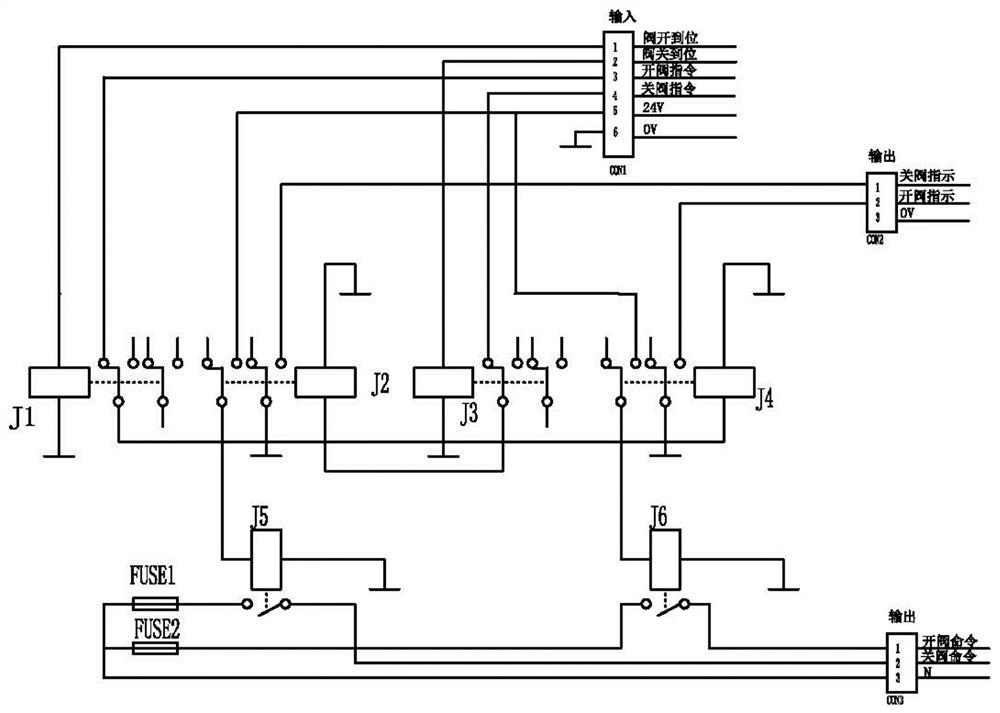

Modular water plant main control unit

PendingCN112255986ASolve various technical problemsChange the way of productionTreatment control/steeringTotal factory controlAgricultural scienceAgricultural engineering

The invention discloses a modular water plant main control unit, and relates to the technical field of water plant control equipment. The main control unit comprises a bus bottom plate, the bus bottomplate is electrically connected with a control module, an analog quantity module, a switch valve plate, an adjusting valve plate and an output plate, and the switch valve plate and the adjusting valve plate are electrically connected with the output plate; and the output plate is electrically connected with a load. The modular water plant main control unit solves the technical problems that in the prior art, a water plant control cabinet is complex in structure, long in production period, high in cost, difficult to modify and maintain and the like. The modular water plant main control unit issimple in structure, convenient and rapid to assemble and quality check and high in percent of pass; the use failure rate is low, and maintenance is easy; modification and expansion are simple; and the cost is low.

Owner:SHANDONG HOTONE ENVIRONMENT TECH CO LTD

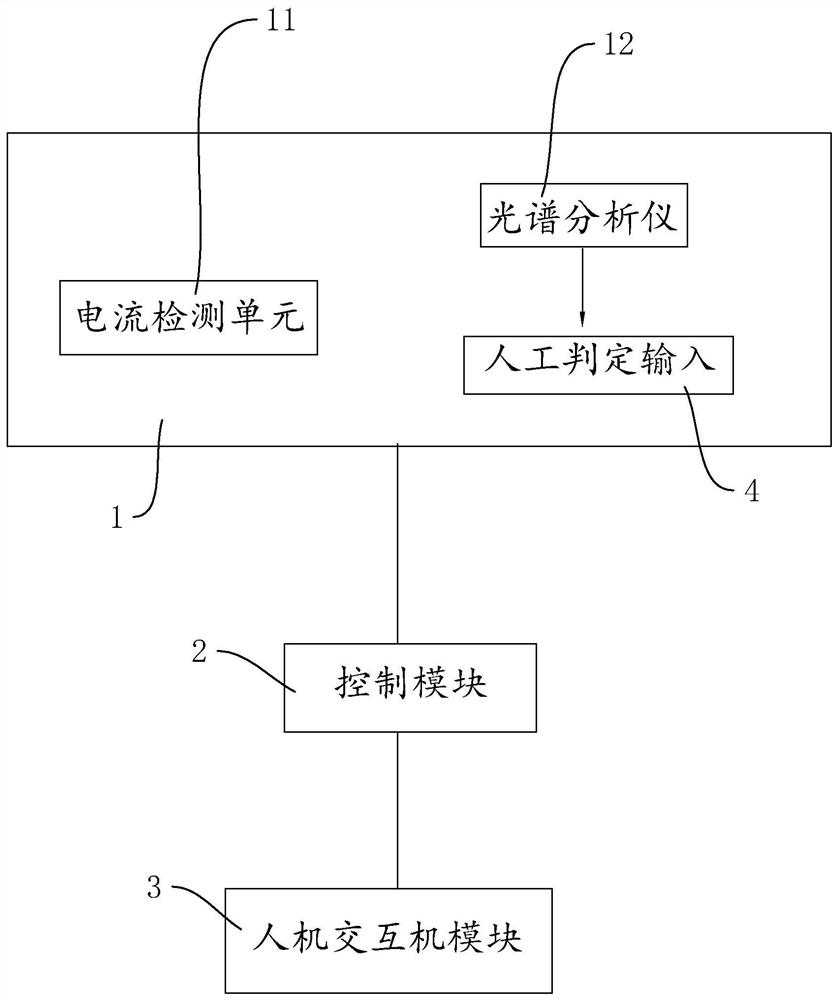

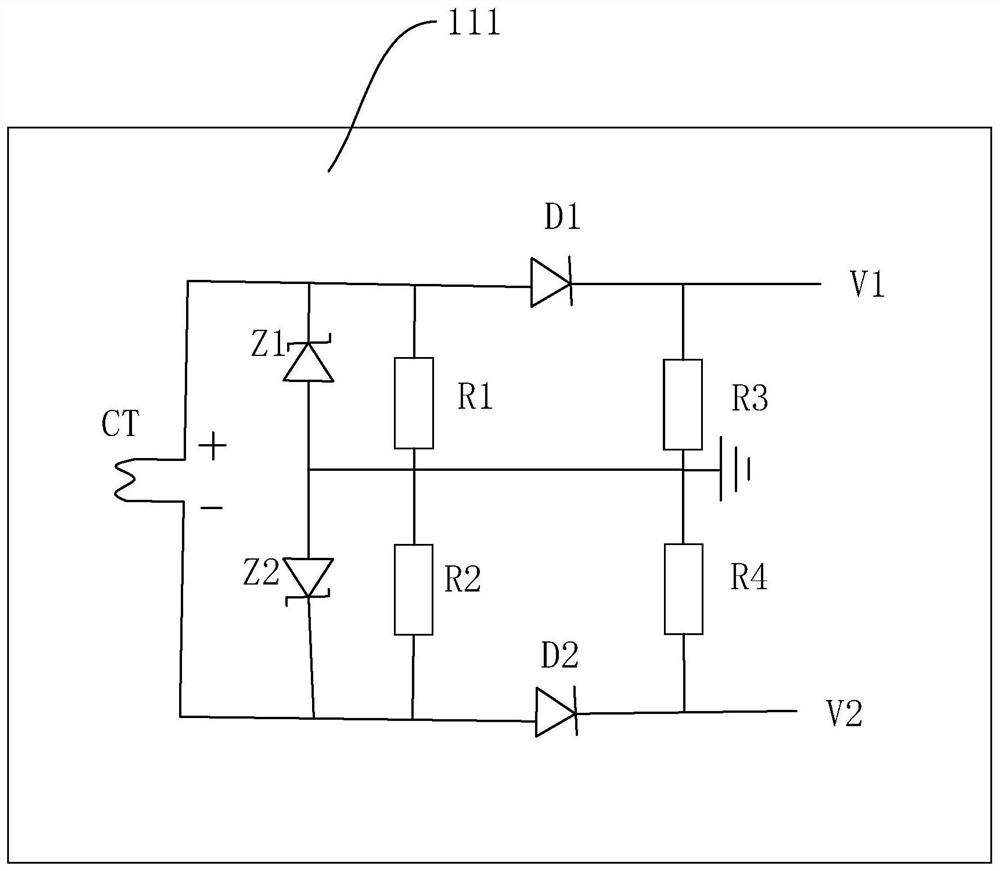

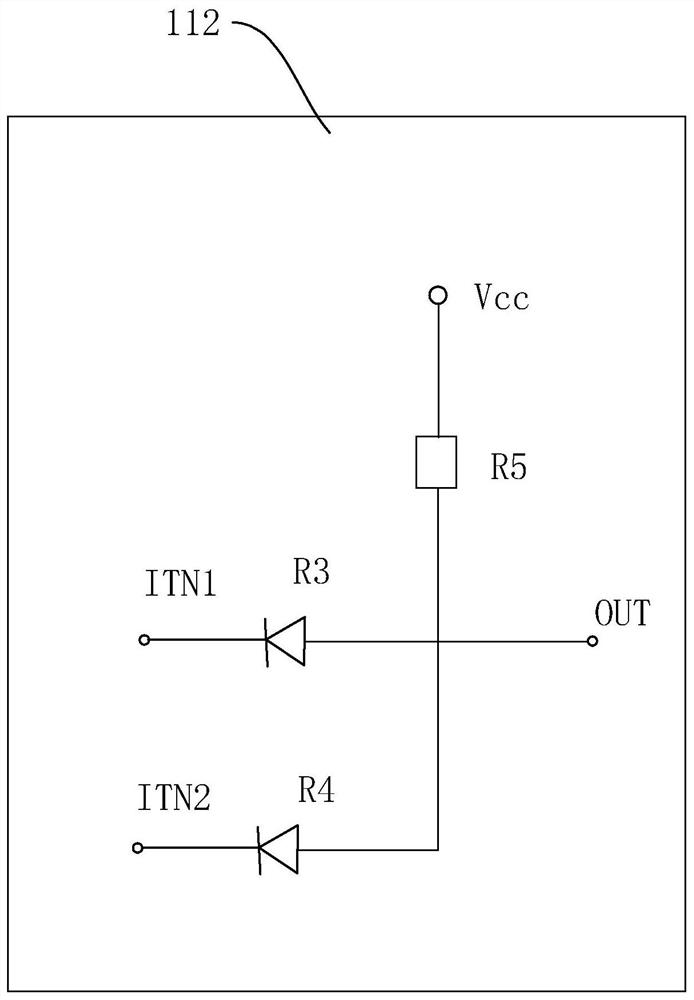

Light color consistency control system for led floodlights

ActiveCN110278633BEasy to control light color consistencyGuaranteed quality effectElectrical apparatusElectroluminescent light sourcesControl systemEngineering

The invention discloses a light color consistency control system for LED floodlight lamps, relates to the field of LED lamp control, and aims to solve the problem that the light color consistency of the existing LED floodlights shipped out of the factory is relatively poor, and the main points of the technical scheme Yes: It includes a detection module for collecting data of floodlights, a control module coupled to the detection module, and a human-computer interaction module coupled to the control module. The current detection unit, the control module controls the human-computer interaction module to output the detection result of the lamp according to the signal fed back by the detection module. The light color consistency control system of the LED projecting light fixture of the present invention can be used for quality inspection of manufactured products, which is convenient for staff to control the light color consistency of the manufactured products and ensures the quality of the manufactured products.

Owner:安徽华新光电饰业有限公司

A Two-Stage Coating Heterogeneous Synchronous Composite Membrane Preparation Device

ActiveCN110681269BReduce processConvenient quality inspectionSemi-permeable membranesProcess engineeringTensile testing

Owner:宁波建嵘科技有限公司

Plate hole reaming conveying device for copper pipe

ActiveCN114558937BAchieve clampingRealize the clamping effectShaping toolsMetal-working feeding devicesStructural engineeringMechanics

Owner:常州九洲创胜特种铜业有限公司

Cable connection mechanism for data storage cabinet

ActiveCN113612041AOptimize workflowAvoid injury hazardElectric connection structural associationsCable junctionsCopper wireStructural engineering

The invention relates to the technical field of cable connection and particularly relates to a cable connection mechanism for a data storage cabinet. The mechanism comprises a connection shell, wherein guide wire through holes are formed in two ends of the connection shell, fixing sleeves are connected to two ends of the connection shell, cable fixing sleeves are mounted at two ends of the two fixing sleeves, the cable fixing sleeves are fixedly connected with wiring sleeve shells, the connecting shell, the fixing sleeves, the cable fixing sleeves and the wiring sleeve shells wrap the thermoplastic pipeline on the surface after cables are connected, a contact element is fixedly connected into the connecting shell, and two first limiting bolts are arranged in a reverse mirror image mode. According to the mechanism, a copper wire can be firmly fixed on the contact element, the traditional working process of winding the copper wire on the contact element is replaced, the cable connection process is simplified, labor input is reduced, hidden danger of injury of workers is avoided, and connection efficiency of the cable and the contact element is improved.

Owner:南通屹洲网络科技有限公司

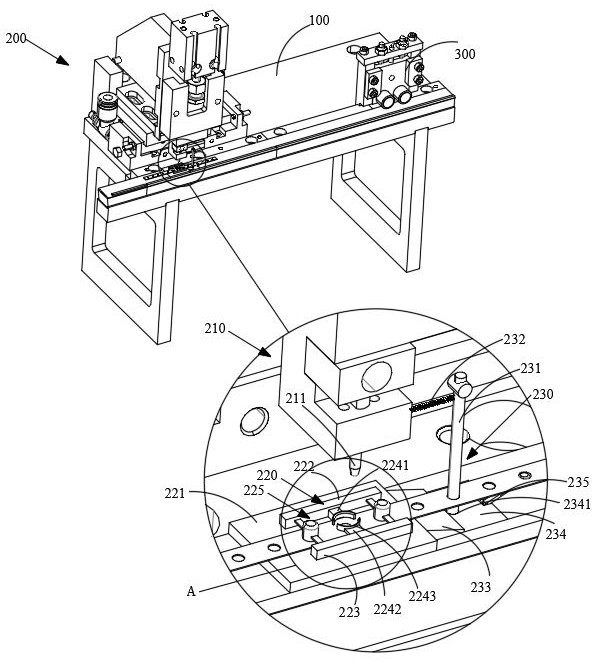

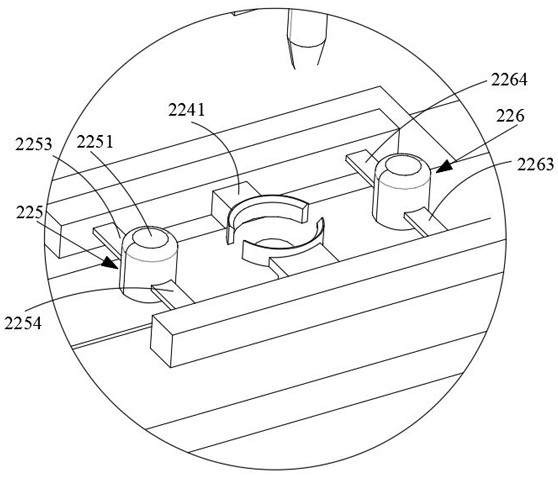

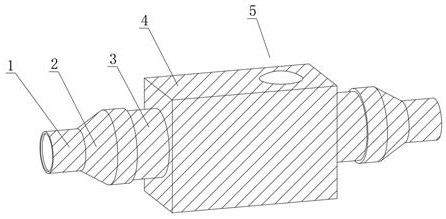

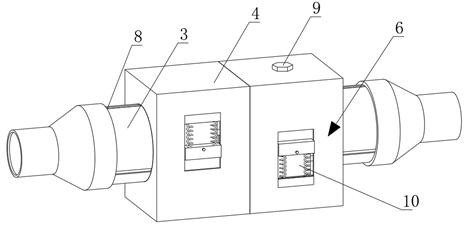

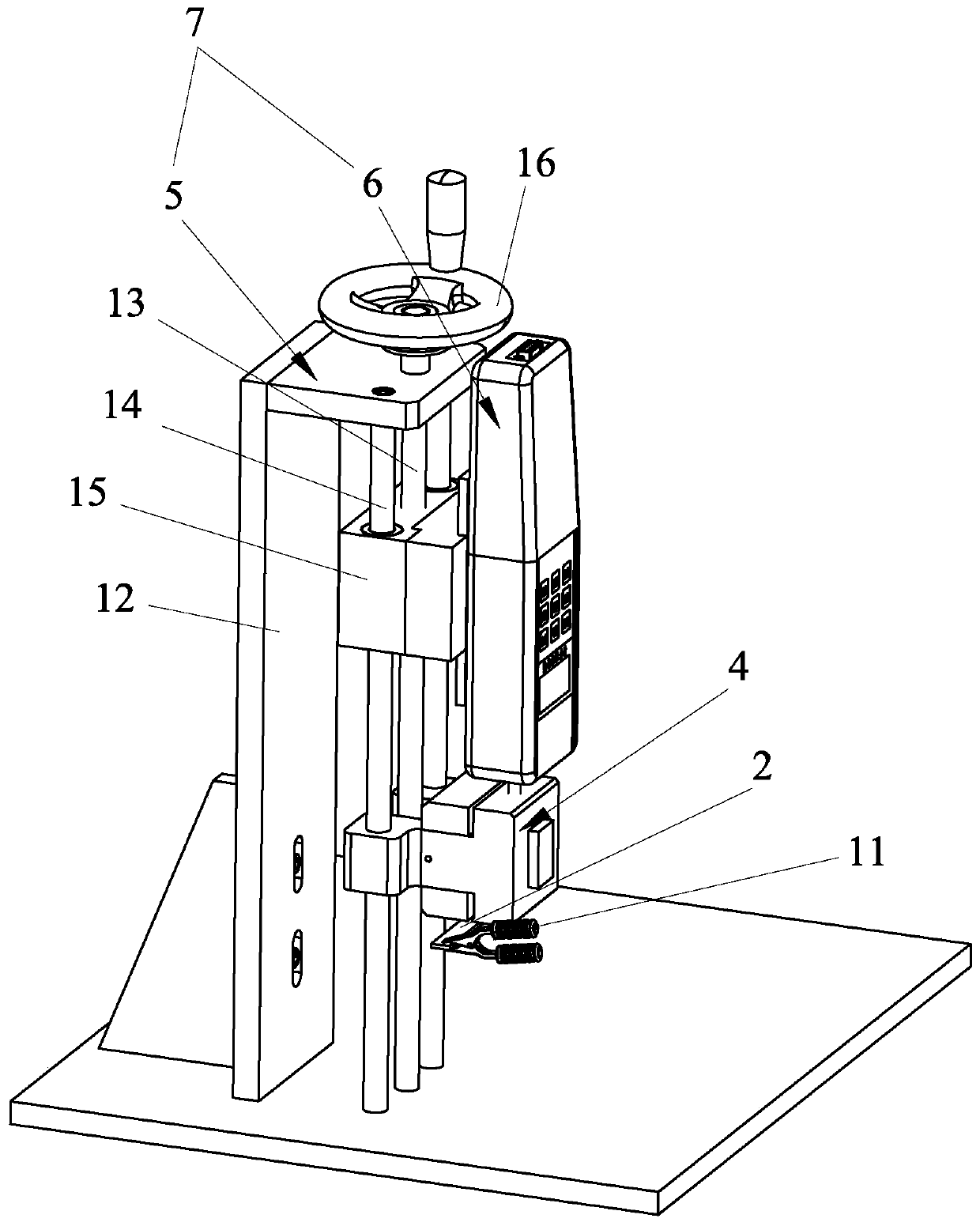

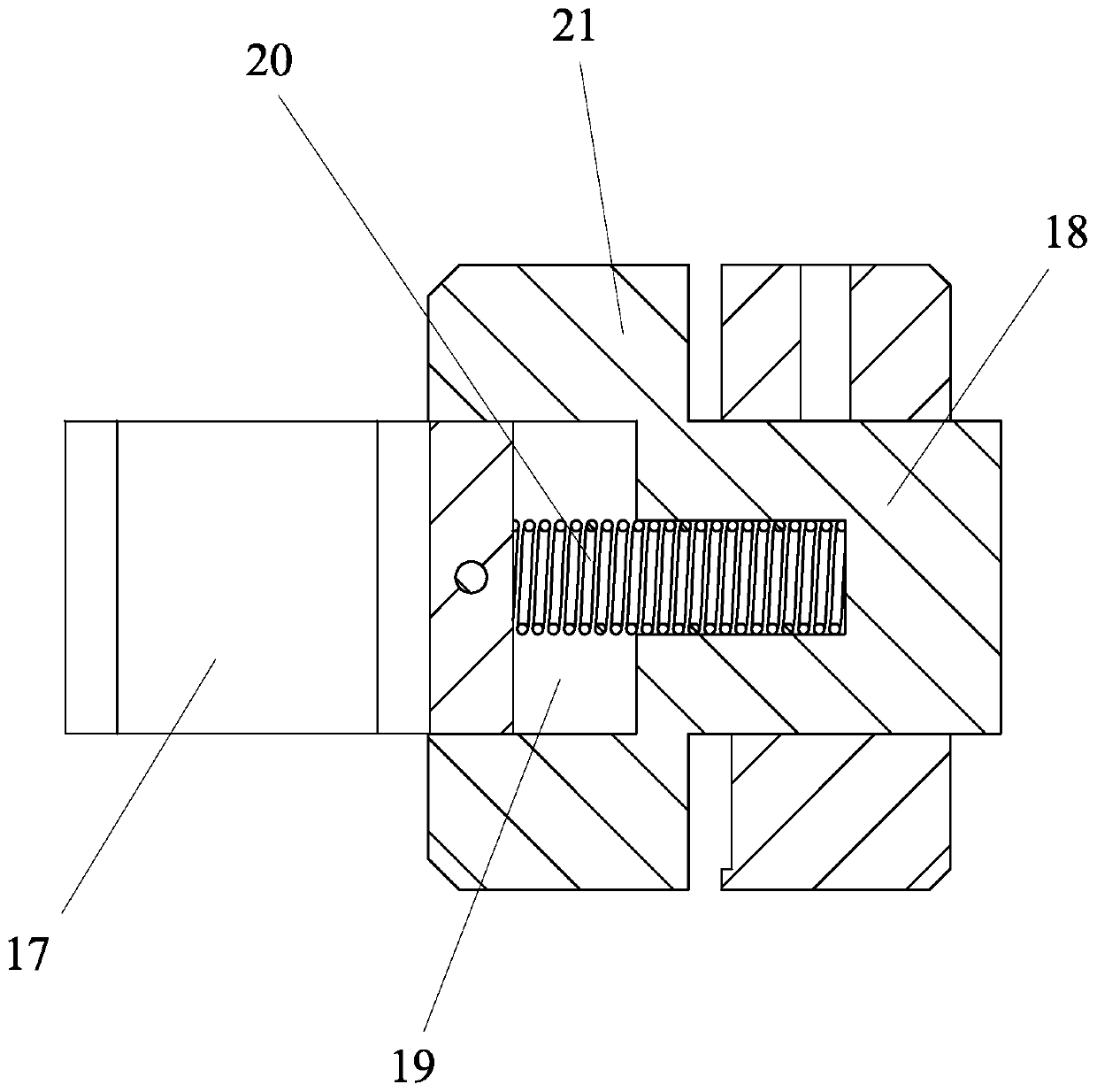

Rapid testing device for contact resistance of welding type electrical contact element and testing method of device

PendingCN110514901AEasy to detectImprove detection efficiencyResistance/reactance/impedenceElectrical resistance and conductanceElectricity

The invention discloses a rapid testing device for contact resistance of a welding type electrical contact element and a testing method of the device. The welding type electrical contact element comprises a first to-be-tested workpiece and a second to-be-tested workpiece, wherein the first to-be-tested workpiece comprises a first conductive substrate welded with a first sheet-shaped contact, and the second to-be-tested workpiece comprises a second conductive substrate welded with a second sheet-shaped contact; the device further comprises a clamping mechanism used for fixing the first to-be-tested workpiece, a clamping mechanism used for clamping the second to-be-tested workpiece, a force applying mechanism used for pressing the second to-be-tested workpiece on the first to-be-tested workpiece and a resistance testing mechanism used for testing a resistance value when the first to-be-tested workpiece and the second to-be-tested workpiece are in contact with each other in a extruded manner; one end of the resistance testing mechanism is electrically connected to the first conductive substrate, and the other end of the resistance testing mechanism is electrically connected to the second conductive substrate; and the first sheet-shaped contact and the second sheet-shaped contact are oppositely extruded. According to the device and the method, the detection efficiency of the contact resistance of the welding type electrical contact element can be improved, and the device and the method have the characteristics of being simple in structure and easy to operate.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com