Plate hole reaming conveying device for copper pipe

A conveying device and plate technology, applied in the field of conveying, can solve problems such as troublesome operation, and achieve the effect of improving the pass rate and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

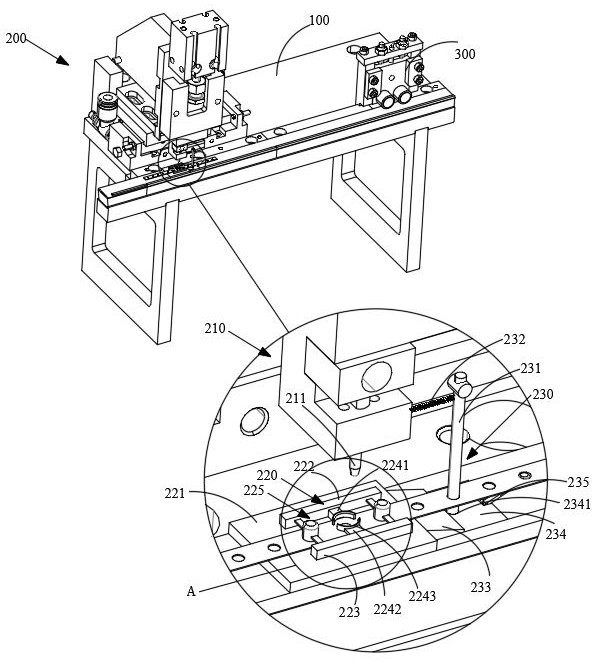

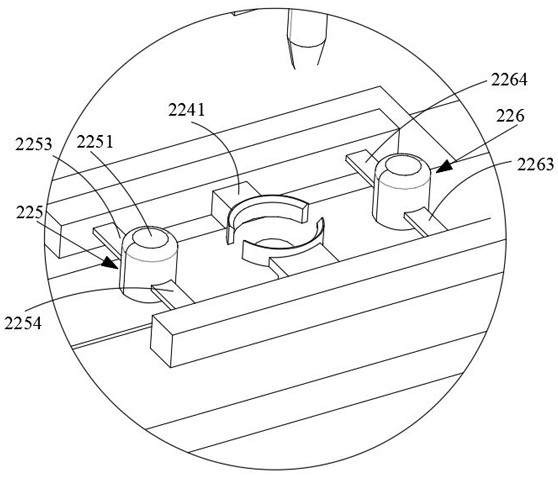

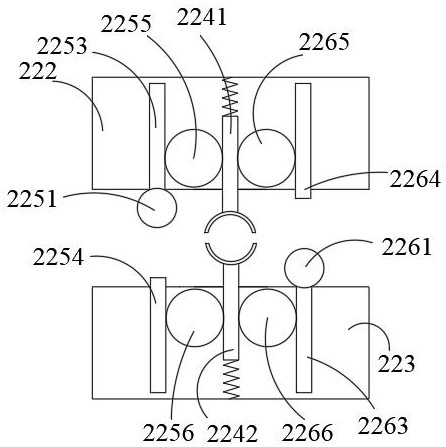

[0079] see Figure 1-Figure 5 , this embodiment 1 provides a plate hole reaming and conveying device for copper pipes, including: a workbench 100 and a hole expansion mechanism 200; the hole expansion mechanism 200 is arranged on the workbench 100 and is suitable for the plate Equally spaced reaming; the reaming mechanism 200 includes a reaming component 210, a reaming base 220 and a pushing component 230; the reaming base 220 is arranged on the worktable 100; the reaming component 210 is arranged on the The reaming base 220 is above the reaming base 220 and is suitable for reaming the plate on the reaming base 220; the pushing component 230 is disposed at the discharge end of the reaming base 220 and is suitable for expanding the plate Push the end of the hole back.

[0080] Specifically, the pusher assembly 230 includes a push rod 231, a return spring 232 and an oblique slider 233; the oblique slider 233 is fixedly arranged on the discharge side of the reaming base 220; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com