Flat chopstick turnover device

A technology of a turning device and a rotating shaft, which is applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inconvenient transfer of chopsticks, high production cost, complicated structure, etc., and achieves convenient continuous transfer and turning and low production cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

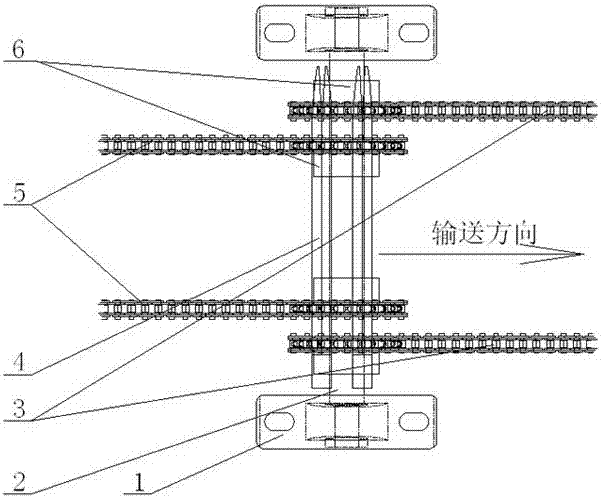

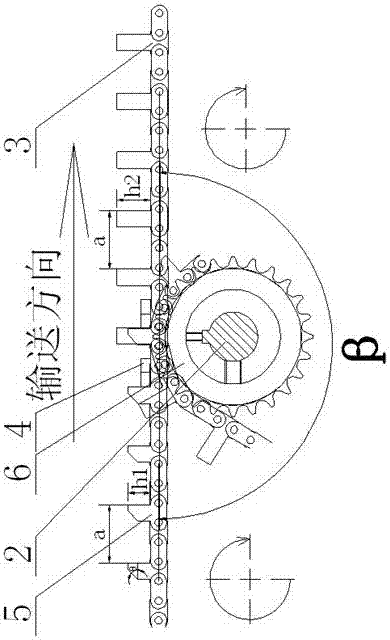

[0030] refer to Figure 1~5 , a chopsticks turning device in this embodiment, comprising a first horizontal transmission chain 5 and a second horizontal transmission chain 3 arranged in sequence along the transmission direction of the chopsticks 4; the end of the first horizontal transmission chain 5 is connected to the second horizontal transmission chain The front end of the chain 3 is installed on the same rotating shaft 2 through the sprocket wheel 6, so that the linear speed of both operations is the same; the two ends of the rotating shaft 2 are fixed on the frame.

[0031] The first horizontal conveying chain 5 is positioned in the middle of the second horizontal conveying chain 3, and the distance between the second horizontal conveying chain 3 outside the frame is smaller than the length of the flat chopsticks 4 by 5 cm, ensuring that the first horizontal conveying chain 5 and the second horizontal conveying chain The transmission stability of two horizontal transmiss...

Embodiment 2

[0042] refer to Image 6 with Figure 7 , compared with embodiment 1, the present embodiment is a flat chopsticks turning device, there are the following differences:

[0043] refer to Image 6 , the first horizontal conveyor chain 5 is positioned at the outside of the second horizontal conveyor chain 3, and the distance between the first horizontal conveyor chain 5 or the second horizontal conveyor chain 3 positioned outside the frame is 6cm smaller than the length of the flat chopsticks 4, Ensure the transmission stability of the first horizontal conveyor chain 5 and the second horizontal conveyor chain 3 to the chopsticks 4 .

[0044] refer to Figure 7 , the sprockets 51 of the first horizontal transmission chain 5 are straight teeth, and the sprockets of the second horizontal transmission chain 3 are straight teeth.

[0045] The angle β between the first horizontal conveyor chain and the second horizontal conveyor chain is 180°.

[0046] The height h1 of the first ho...

Embodiment 3

[0048] refer to Figure 8 , compared with embodiment 1, the present embodiment is a flat chopsticks turning device, there are the following differences:

[0049] Described first horizontal conveying chain 5 is positioned at the middle of second horizontal conveying chain 3, is positioned at the spacing between the first horizontal conveying chain 5 outside frame 4.5cm less than the length of flat chopsticks 4, ensures first horizontal conveying chain 5 or The transmission stability of the second horizontal transmission chain 3 to the flat chopsticks 4.

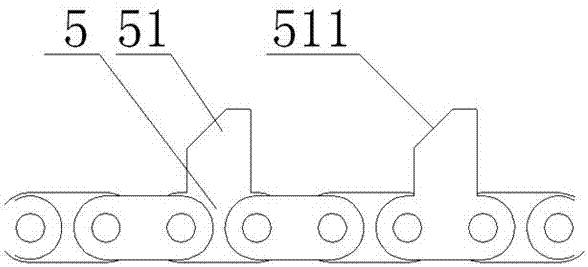

[0050] The sprockets 51 of the first horizontal transmission chain 5 are arc-shaped teeth with a square lower end and an arc-shaped upper end. The arc-shaped teeth can effectively reduce the damage of the sprocket 51 to the chopsticks 4 during the flipping process.

[0051] The chain teeth of the second horizontal conveyor chain 3 are helical teeth. The helical teeth of the second horizontal transmission chain 3 are square wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com