Automatic detonator arranging machine for detonator shells

It is a technology of tube-arranging machine and tube shell, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., and can solve problems such as low work efficiency, tube shell blockage, and loose intubation, and achieve high tube loading rate and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

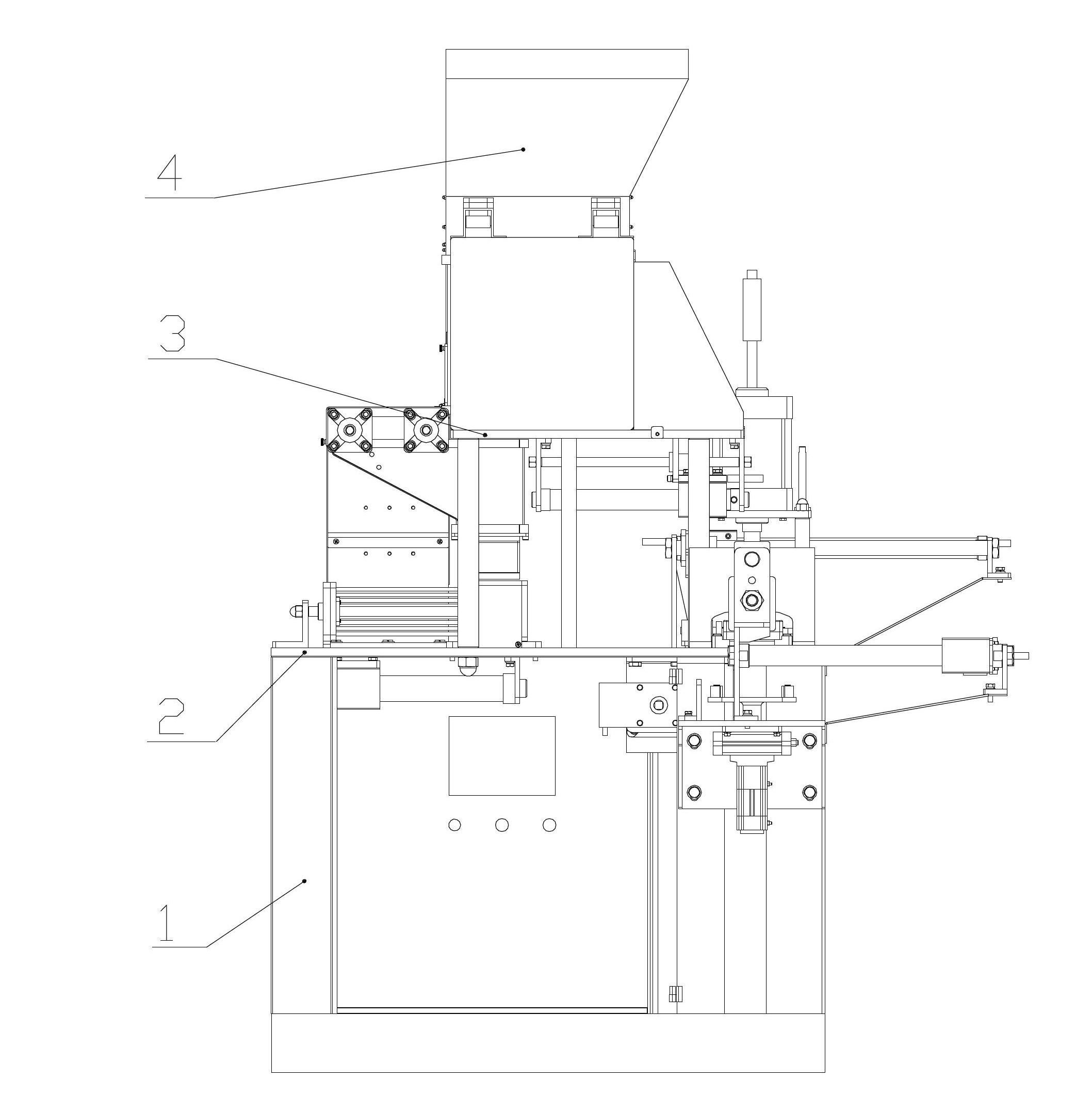

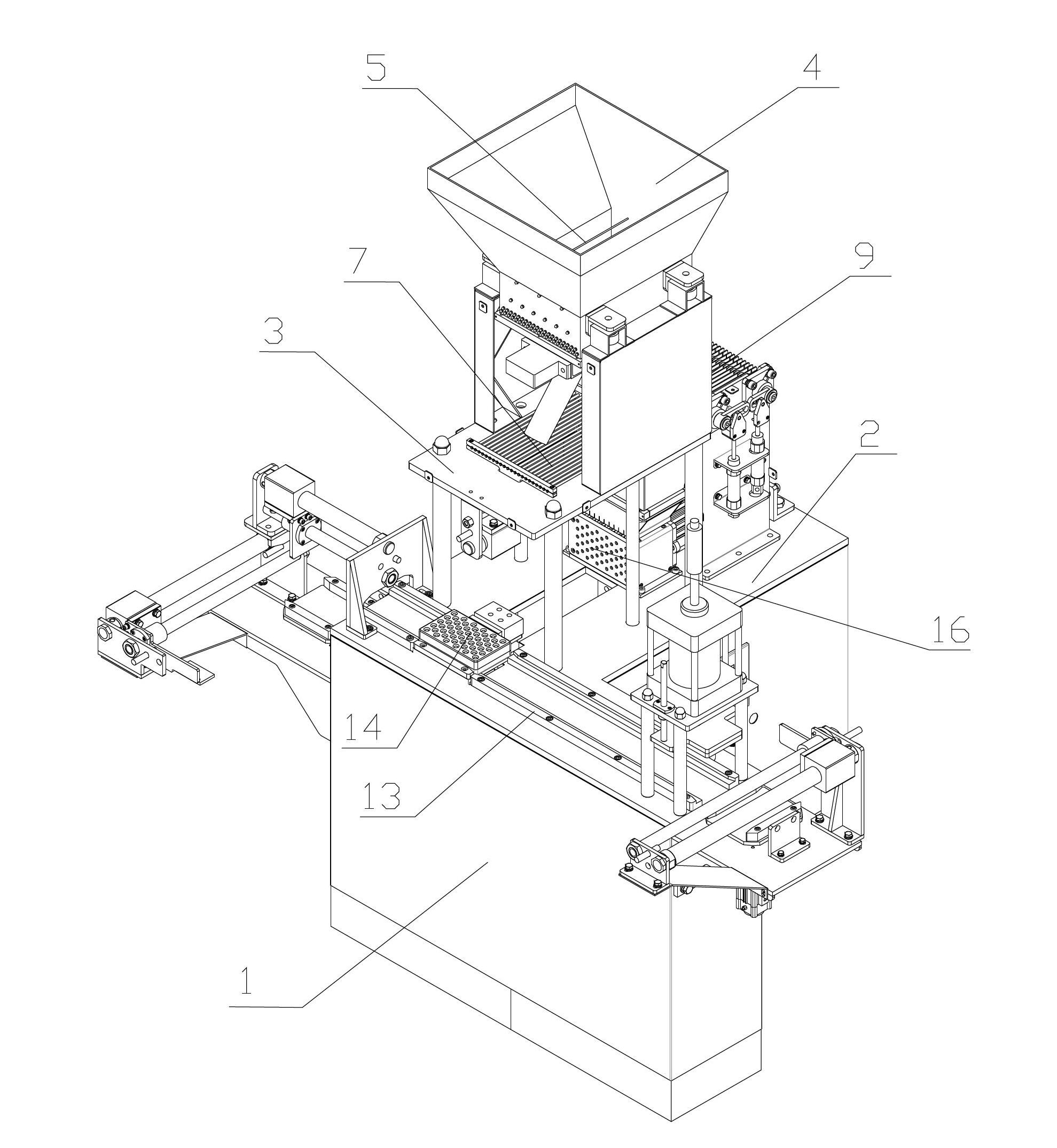

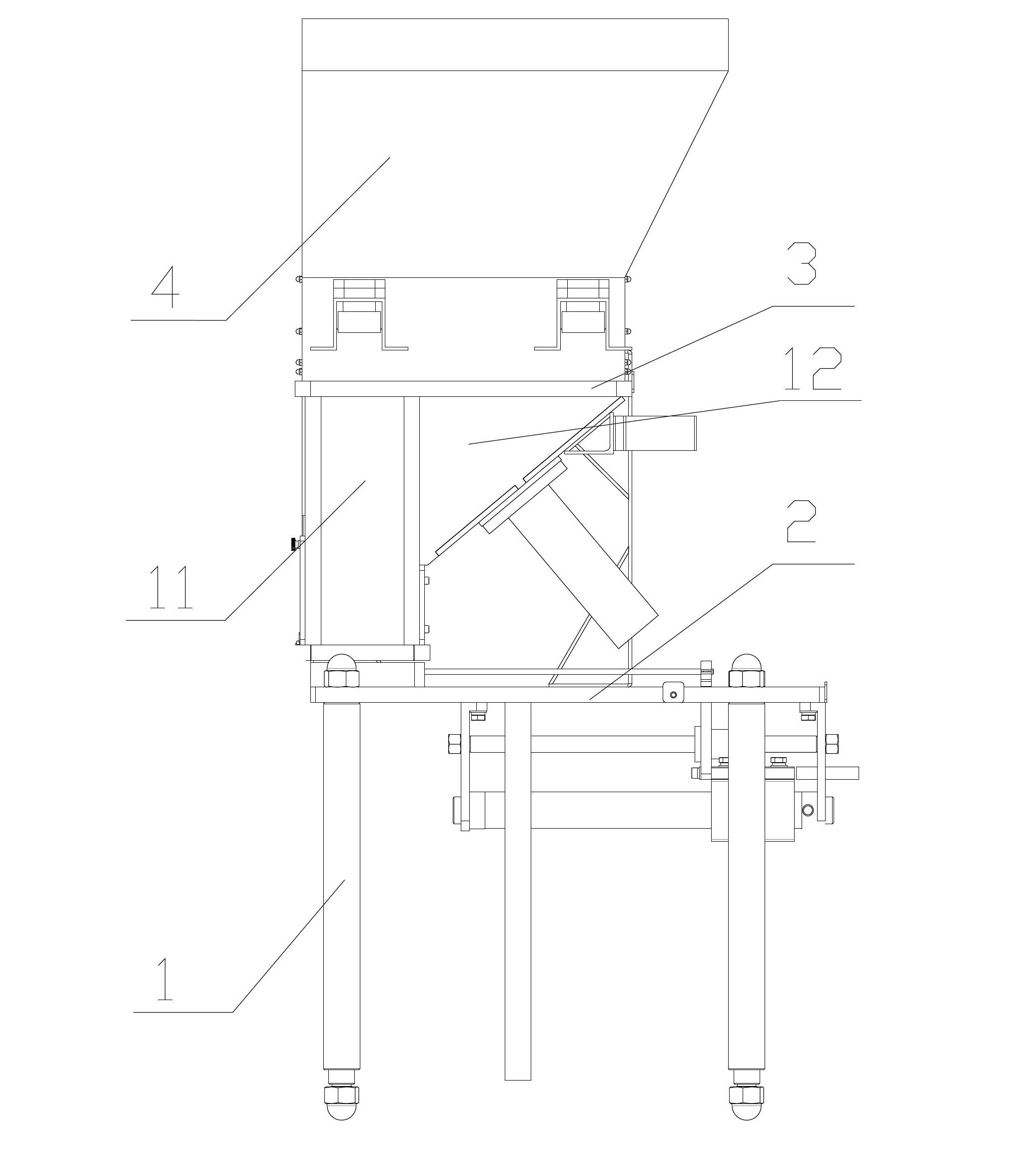

[0038] see Figure 1 to Figure 8 , a kind of detonator casing automatic pipe arrangement machine, including the lower table 2 and the upper table 3 supported by the frame 1, the casing orientation device is arranged above the upper table 3, the upper table 3 and the lower table 2 can be It is connected by a column, and can be equipped with a shell adjustment device and a mold loading device. The shell orientation device makes the shells lined up in the horizontal and vertical directions, and the shell adjustment device adjusts the orientation of the opening end of the shell to make them consistent; the mold loading device Then snap the closed end of the tube shell into the hole of the collecting mold 14 .

[0039]The shell orienting device includes a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com