Rapid testing device for contact resistance of welding type electrical contact element and testing method of device

A contact resistance and testing device technology, applied in the detection field, can solve problems such as inconvenient operation, long operation cycle, and inability to monitor online in time, and achieve the effects of simple and fast detection, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

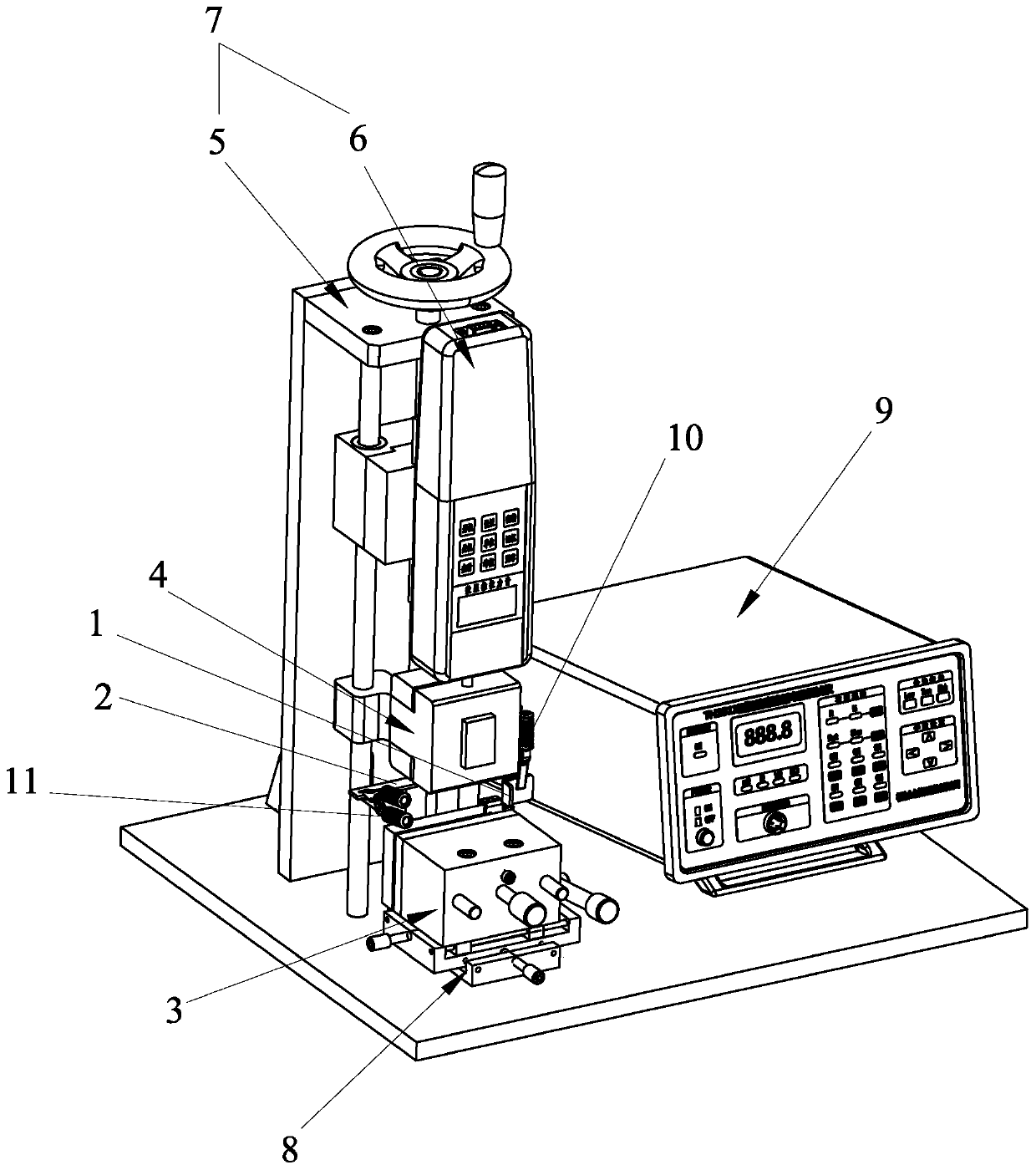

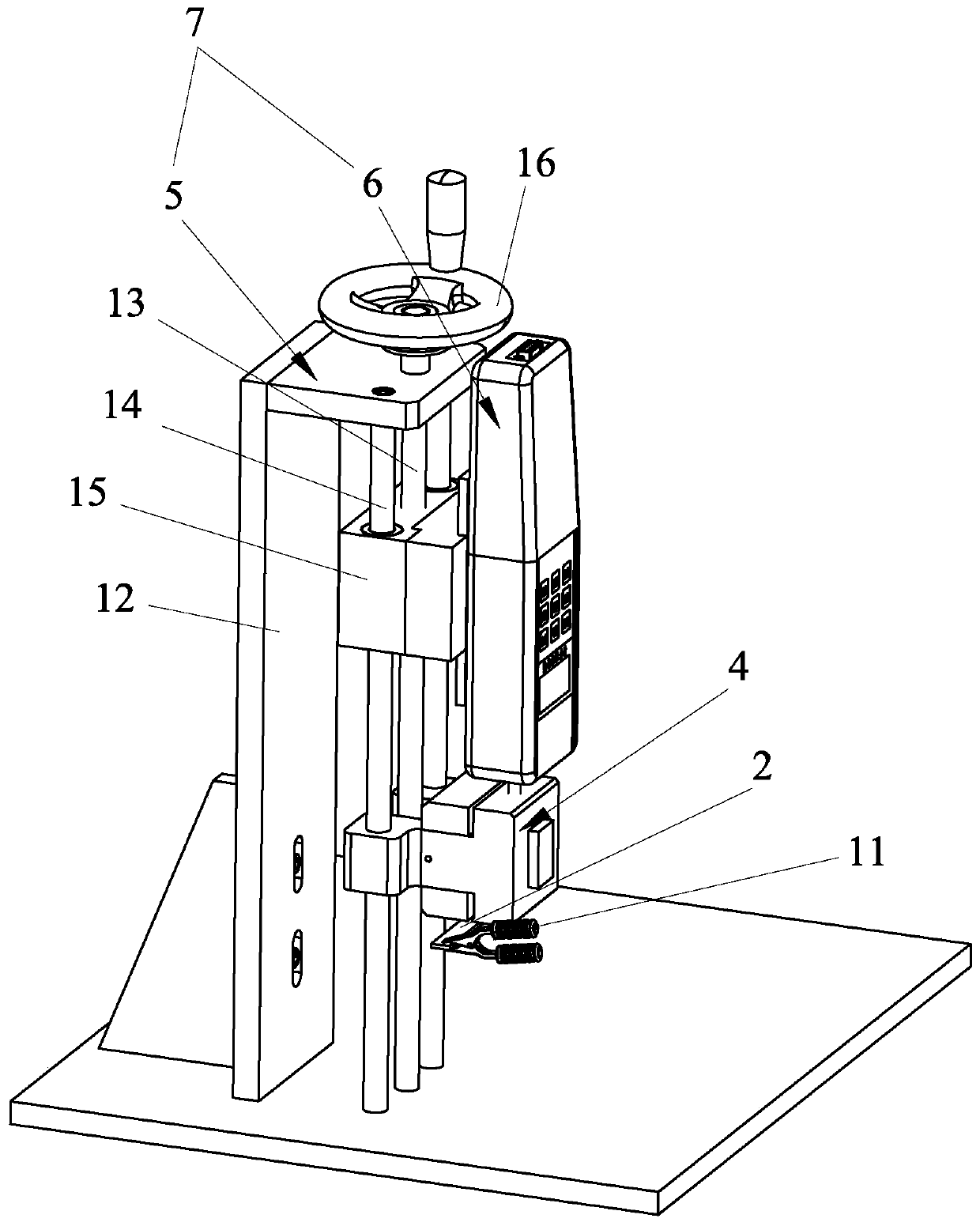

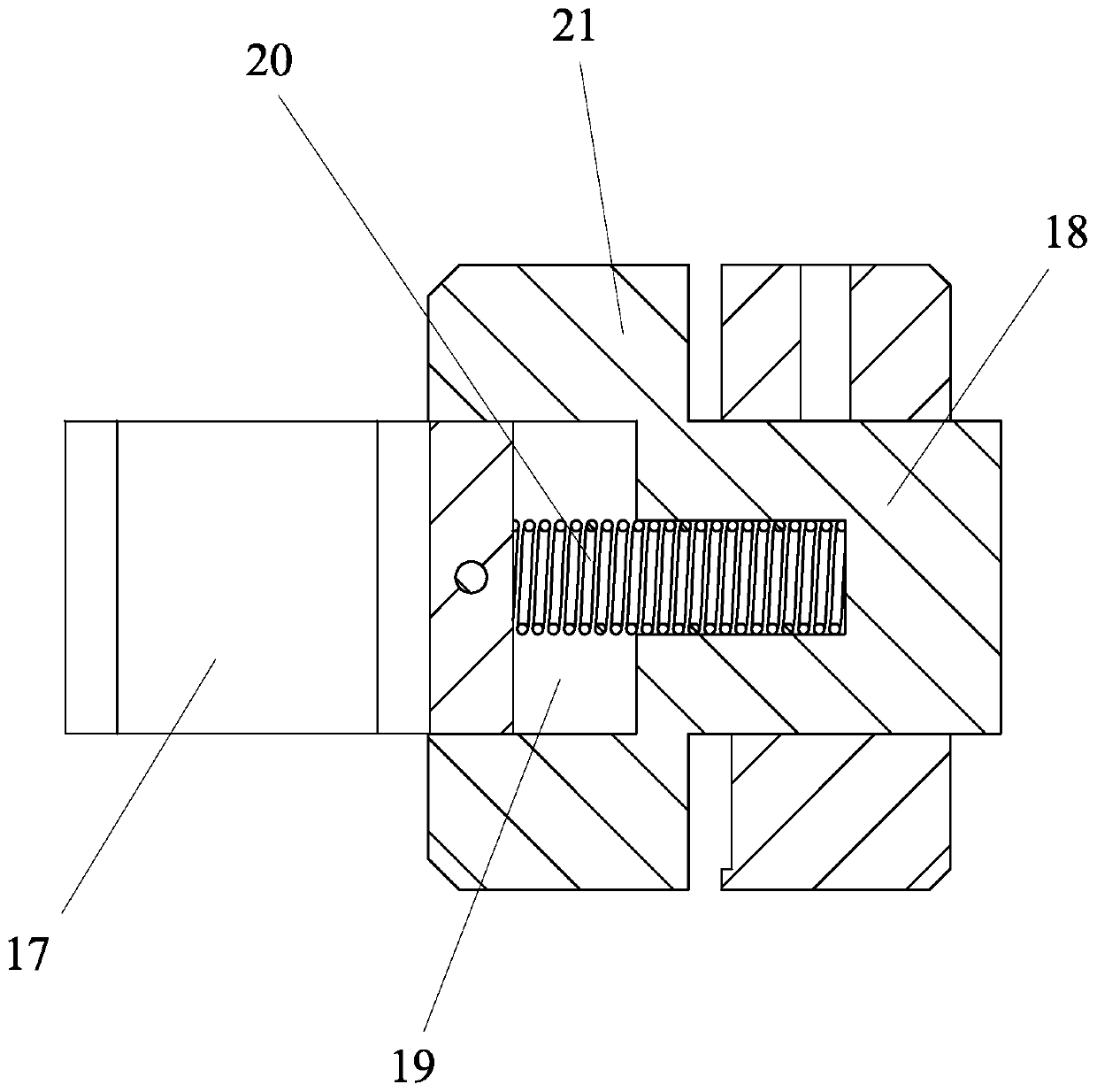

[0037] Embodiment: The quick test device for the contact resistance of welded electric contact elements, as attached Figure 1-9As shown, the welded electrical contact element includes a first workpiece to be tested 1 and a second workpiece to be tested 2, and the first workpiece to be tested 1 includes a first conductive base 38 on which a first sheet is welded. Shape contacts 39, the second workpiece 2 to be measured includes a second conductive substrate 40, the second conductive substrate 40 is welded with a second sheet contact 41, and also includes a clamp for fixing the first workpiece to be measured 1 Mechanism 3, a clamping mechanism 4 for clamping the second workpiece 2 to be measured, a force applying mechanism 7 for pressing the second workpiece 2 to be measured on the first workpiece 1 to be measured, and a force applying mechanism 7 for testing the first workpiece to be measured The resistance test mechanism 9 of the resistance resistance value when the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com