High-sensitivity telephone receiver vibrating diaphragm

A high-sensitivity, receiver technology, applied in the direction of sensors, sensor types, electromechanical sensors, etc., can solve the problems of easy distortion of the receiver, low diaphragm rigidity, unstable connection, etc., and achieve low processing difficulty and large bonding area , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

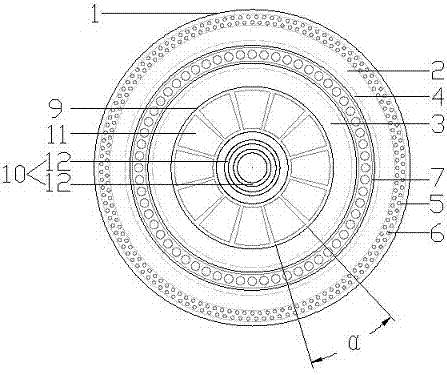

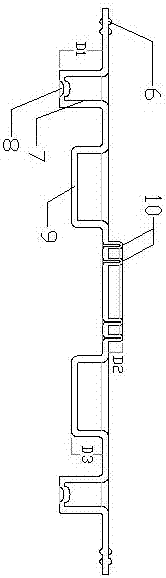

[0018] A high-sensitivity receiver diaphragm as shown in the figure includes a diaphragm main body 1, which is characterized in that the diaphragm main body 1 is circular and includes a fixed part 2 located on the outside, a middle part 3 located in the middle and The connection part 4 between the fixed part 2 and the middle part 3, the fixed part 2, the middle part 3 and the connection part 4 are of an integrated structure;

[0019] The fixed portion 2 is circular, and symmetrical fixed regions 5 are arranged on the upper and lower sides of the circular shape, and a plurality of fixed protrusions 6 are arranged in the fixed region 5, and the fixed protrusions The cross-section of 6 is semicircular, and the plurality of fixed protrusions 6 on the same side are arranged at equal intervals, and are evenly distributed in a circular ring. The connecting protrusion 7 is in the shape of a ring, protruding from the upper end surface of the diaphragm main body 1 toward the lower end s...

Embodiment 2

[0026] The diaphragm main body described in Embodiment 1 is a plastic diaphragm, and its material is PET plastic and glass fiber, and its preparation method is as follows:

[0027] (1) Select reinforced PET plastic particles and put them into the melting equipment;

[0028] (2) Continuously evacuate the inside of the melting equipment until the vacuum degree inside the melting equipment is below 100Pa and maintain it. At the same time, start the melting equipment to melt the PET plastic particles;

[0029] (3) After the PET plastic granules are completely melted, add glass fibers that account for 20% of the total mass of the PET plastic granules online, and continue heating with slow stirring at a rate of 30 r / min until the glass fibers are completely melted and combined with the PET plastic Mix evenly to obtain a molten liquid;

[0030] (4) Send the molten liquid obtained in step (3) to MCP three-layer co-extrusion, and stretch it to form a diaphragm sheet;

[0031] (5) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com