Automobile part punching equipment

A technology of auto parts and punching, which is applied in the field of parts manufacturing, can solve the problems of troublesome parts picking and high manual labor intensity, and achieve the effects of convenient quality inspection, improving punching efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

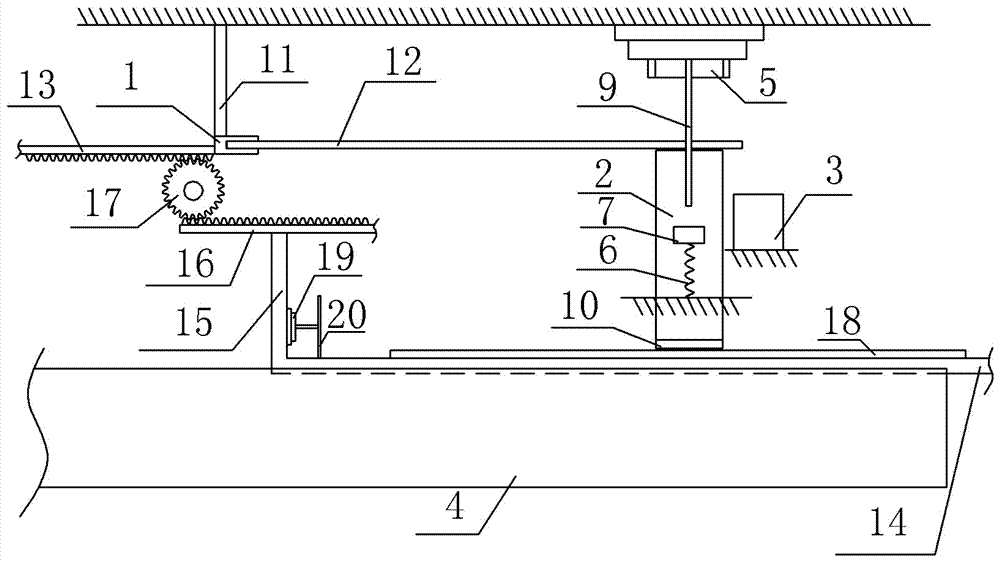

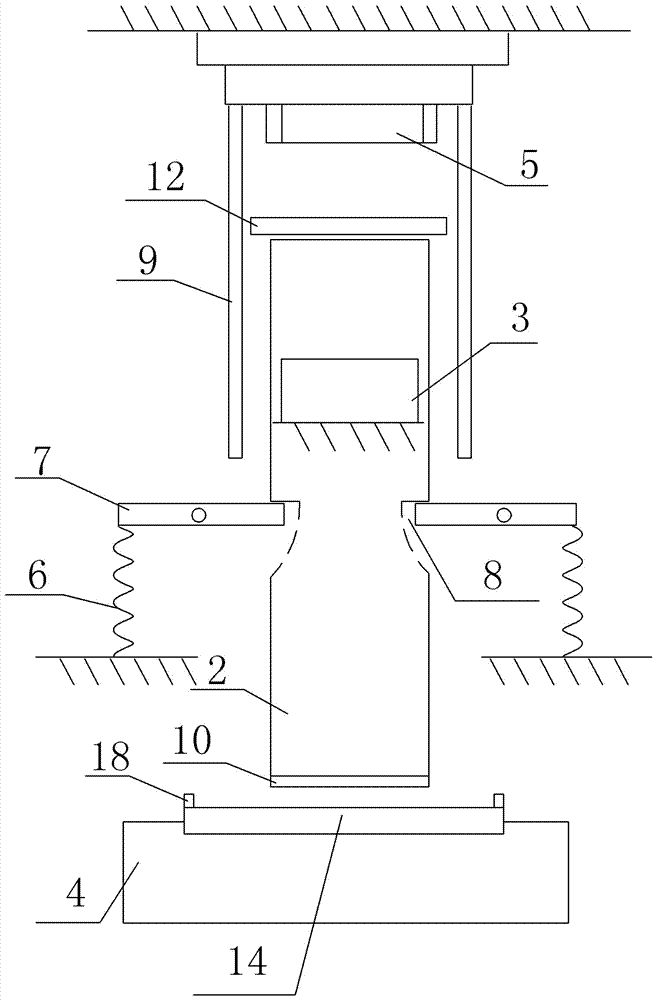

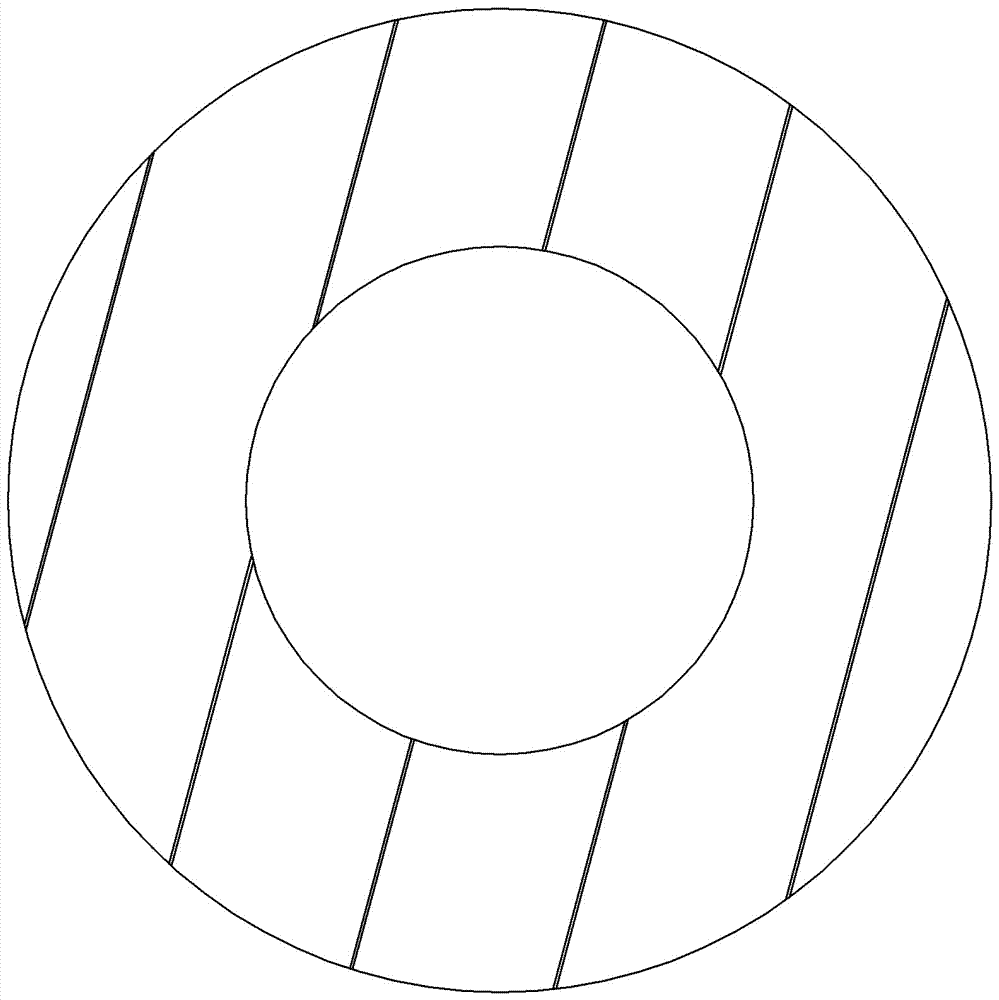

[0016] The reference signs in the drawings of the description include: clamping pliers 1, lower mold 2, waste box 3, base 4, punch 5, extension spring 6, support bar 7, card slot 8, pressing rod 9, rubber pad 10 , slide bar 11, steel plate 12, first rack 13, horizontal transfer plate 14, vertical transfer plate 15, second rack 16, gear 17, baffle plate 18, cylinder 19, push plate 20.

[0017] Such as figure 1 The punching equipment for auto parts shown includes a punching machine, a servo motor, a clamp 1 , a cylindrical lower mold 2 , a waste box 3 , two supporting mechanisms, a transfer plate and a base 4 . The servo motor and the punching machine are connected in series through the controller, and the controller is used to control the start and stop of the servo motor and the punching machine. The punching machine is fixed on the frame, and the punching machine incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com