Double-material injection moulding machine and forming method thereof

An injection molding machine and injection molding technology, applied in the direction of coating, etc., can solve the problems of adverse effects of products, inconvenient operation, and low precision of synthetic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

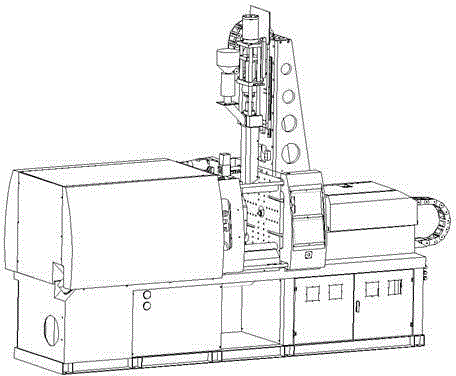

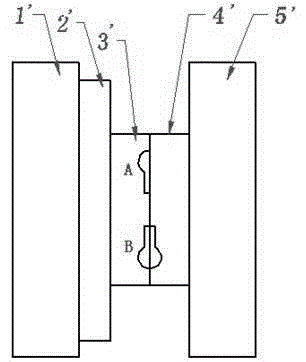

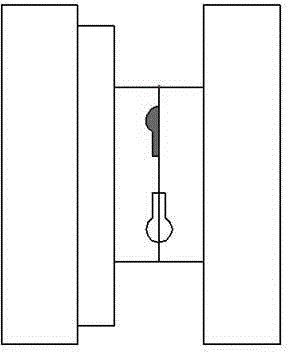

[0045] The double-material injection molding machine of the present invention includes a mold clamping mechanism, a turntable mechanism, a plastic injection mechanism, a liquid silicone injection program mechanism, a plastic heating and feeding mechanism, a mixer composed of a dynamic screw connected to a static mixing tube, a hydraulic system and electronic control system. Among them, the mold clamping mechanism is a direct pressure mold clamping mechanism of horizontal mold clamping, which is used to complete the opening and closing of the mold. The mold clamping mechanism includes a movable template, a rear mold, a front mold and a fixed template. A set of molds with at least two symmetrical mold cavities can be installed on the end face of the rear template, and a set of molds corresponding to the mold cavities of the rear mold can be installed on the end surface of the front template. The corresponding mold cavities on the end faces together form the appearance shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com