Axial plunger pump

A technology of axial plunger pump and plunger cavity, which is applied in the field of hydraulic pumps, can solve problems such as reduced service life and efficiency, wear of sliding shoes, and high noise, and achieve the effects of improving quality, increasing pressure level, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which should not be regarded as limiting the present invention.

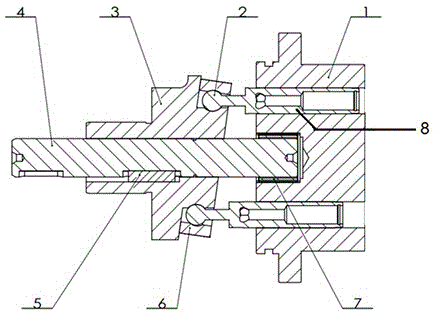

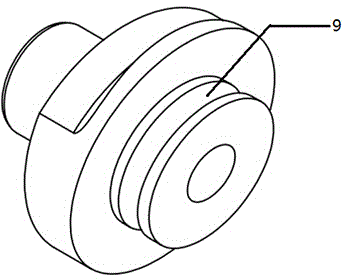

[0021] Such as figure 1 As shown, an axial piston pump is characterized in that it includes a cylinder body 1, a ball plunger 2, an inner ring type swash plate 3, a main shaft 4, a flat key 5, a plunger collar 6, and a needle bearing 7 , plunger chamber 8, the main shaft 4 passes through the central through hole of the inner ring type swash plate 3 and is connected by a flat key 5, so that when the main shaft 4 rotates, the friction between the main shaft 4 and the inner ring type disc 3 is reduced The needle roller bearing 7 is fixed on the cylinder body 1, and the end of the main shaft 4 is connected with the cylinder body 1 through the needle roller bearing 7; Have the first arc groove 9 (such as image 3 shown), the plunger collar 6 is provided with a second arc-shaped groove 10 (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com