Automatic welding equipment for guard bar

An automatic welding and equipment technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of guardrail quality requirements and production cycle that cannot meet market demand, labor intensity of workers, and unstable welding quality. , to achieve the effect of convenient normal production work, short finished product production cycle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

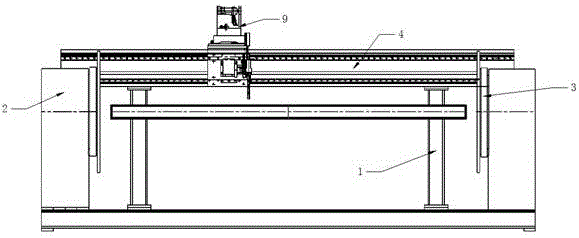

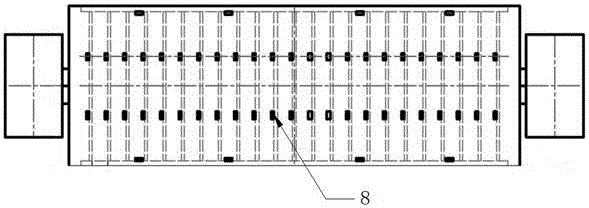

[0017] attached Figure 1-3 It is a specific embodiment of the present invention. The guardrail automatic welding equipment of the present invention includes a longitudinal seam servo deceleration motor traveling mechanism and a servo deceleration motor. Positioning and clamping tooling 8, guardrail positioning and clamping mechanism and electrical control box.

[0018] Specifically, the equipment rack 1 is composed of a guide rail body and a beam guide rail;

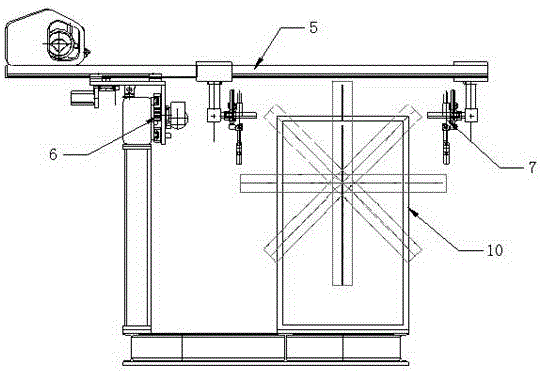

[0019] Specifically, the longitudinal seam servo geared motor traveling mechanism 4 is composed of a servo geared motor 9, a linear slide pair, a precision helical rack and pinion pair 6, and a beam bracket. The servo geared motor 9 is linked with the three-dimensional adjustment mechanism of the welding torch.

[0020] Specifically, the double welding torch adjustment and lifting mechanism 7 is composed of a vertical seam driven suspension arm and two sets of servo motor adjustment gun racks to form a two-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com