A multi-angle adjustable material handling device

A handling device, multi-angle technology, applied in the directions of transportation and packaging, conveyor objects, support frames, etc., can solve the problems of incapable multi-angle adjustment, manual unloading, etc., to avoid manual unloading, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

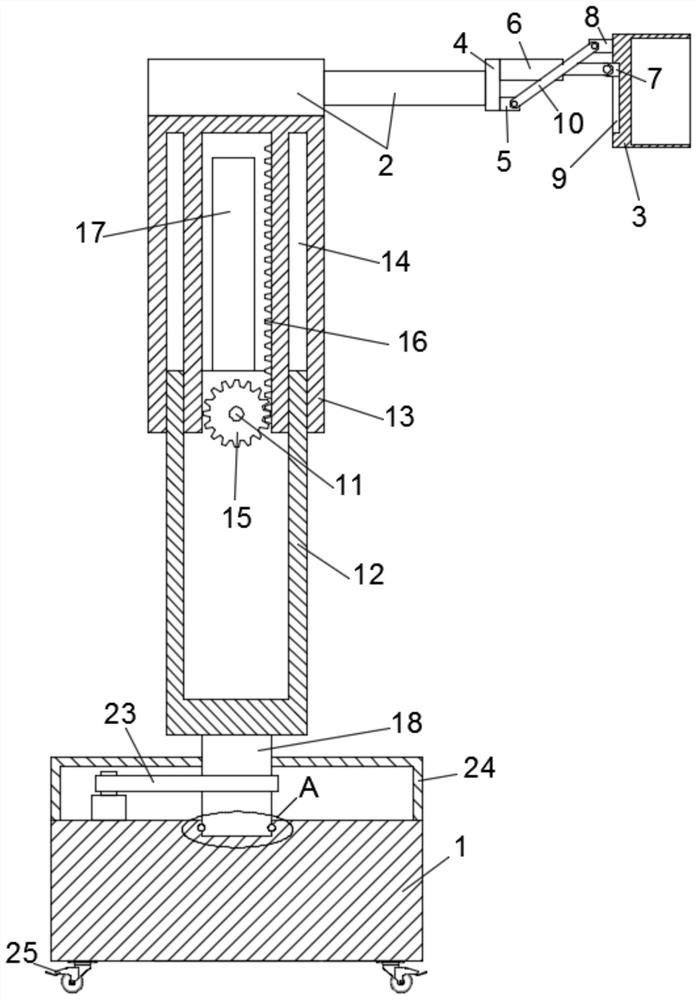

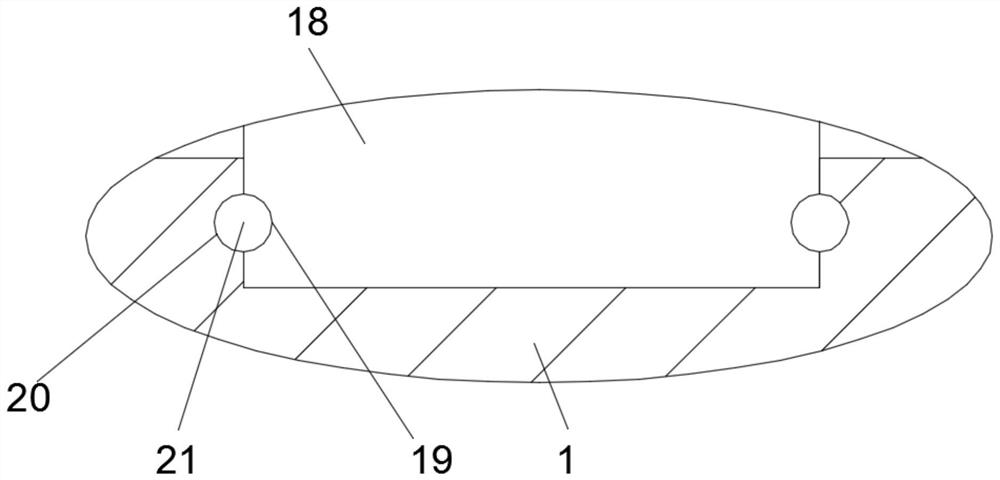

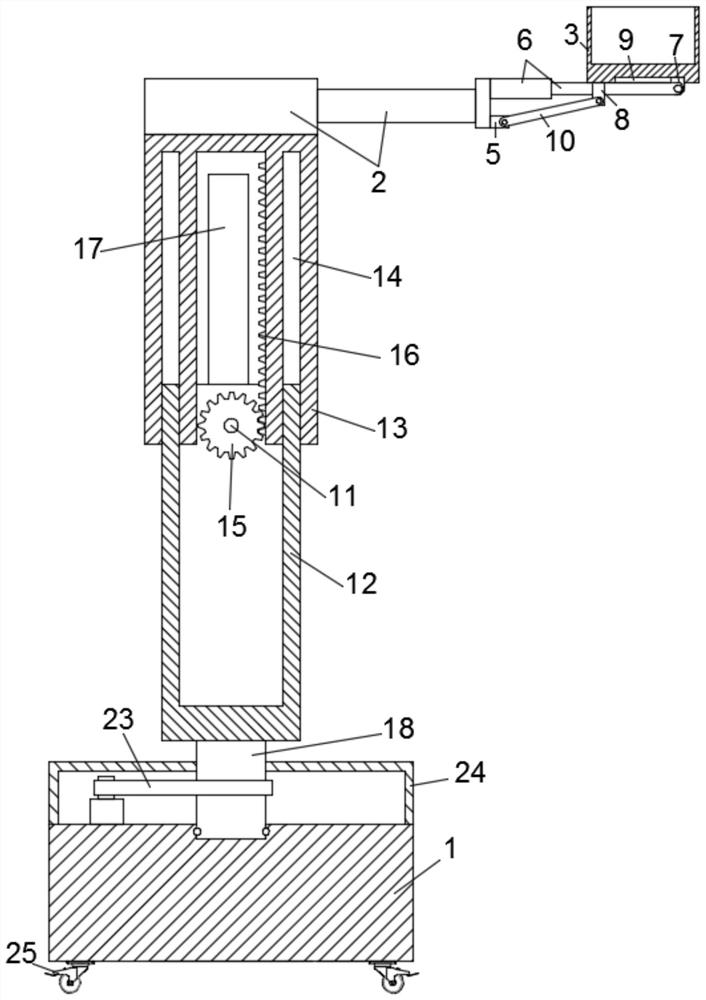

[0022] like Figure 1-3 , a multi-angle adjustable material handling device, including a handling base 1, a lifting assembly and a handling assembly, the lifting assembly is rotatably mounted on the handling base 1, the handling assembly is arranged on the lifting assembly, and the handling assembly includes The lifting cylinder 2 and the transport box 3 are fixedly installed on the lifting assembly, the lifting cylinder 2 is placed horizontally, the telescopic end of the lifting cylinder 2 is fixedly installed with a connecting plate 4, and the first fixing plate 4 is fixedly installed on the connecting plate 4 respectively. Block 5 and pneumatic push rod 6, the telescopic end of the pneumatic push rod 6 is rotated to install the slider 7, the bottom of the transport box 3 is fixedly installed with a second fixing block 8, and the bottom of the transport box 3 is provided with a sliding block 8. Slot 9, the slider 7 is slidably installed in the chute 9, a connecting rod 10 is...

Embodiment 2

[0030] like Figure 4-5, This embodiment is further improved on the basis of Embodiment 1, and the improvement is: the inside of the carrying base 1 is provided with a blind hole 26, the bottom of the carrying base 1 is provided with a symmetrically arranged guide groove 27, and the carrying base 1 is provided with a symmetrically arranged guide groove 27. 1 is provided with a positioning assembly, the positioning assembly includes a biaxial drive motor 28 and a motor bracket 29 for fixedly installing the biaxial drive motor 28, the motor bracket 29 is fixedly installed in the blind hole 26, and the biaxial drive Positioning units are symmetrically arranged on the output shafts on both sides of the motor 28. The positioning units include a fixing plate 30 fixedly installed at the output end of the biaxial drive motor 28. An eccentric shaft pin 31 is fixedly installed on the fixing plate 30. The eccentric shaft The transition link 32 is rotated and installed on the pin 31, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com