Powder metallurgy dust removing device

A dust removal device and powder metallurgy technology, applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of flying dust, poor working environment of workers, waste of powder, etc., and achieve simple production process and good dust removal effect. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

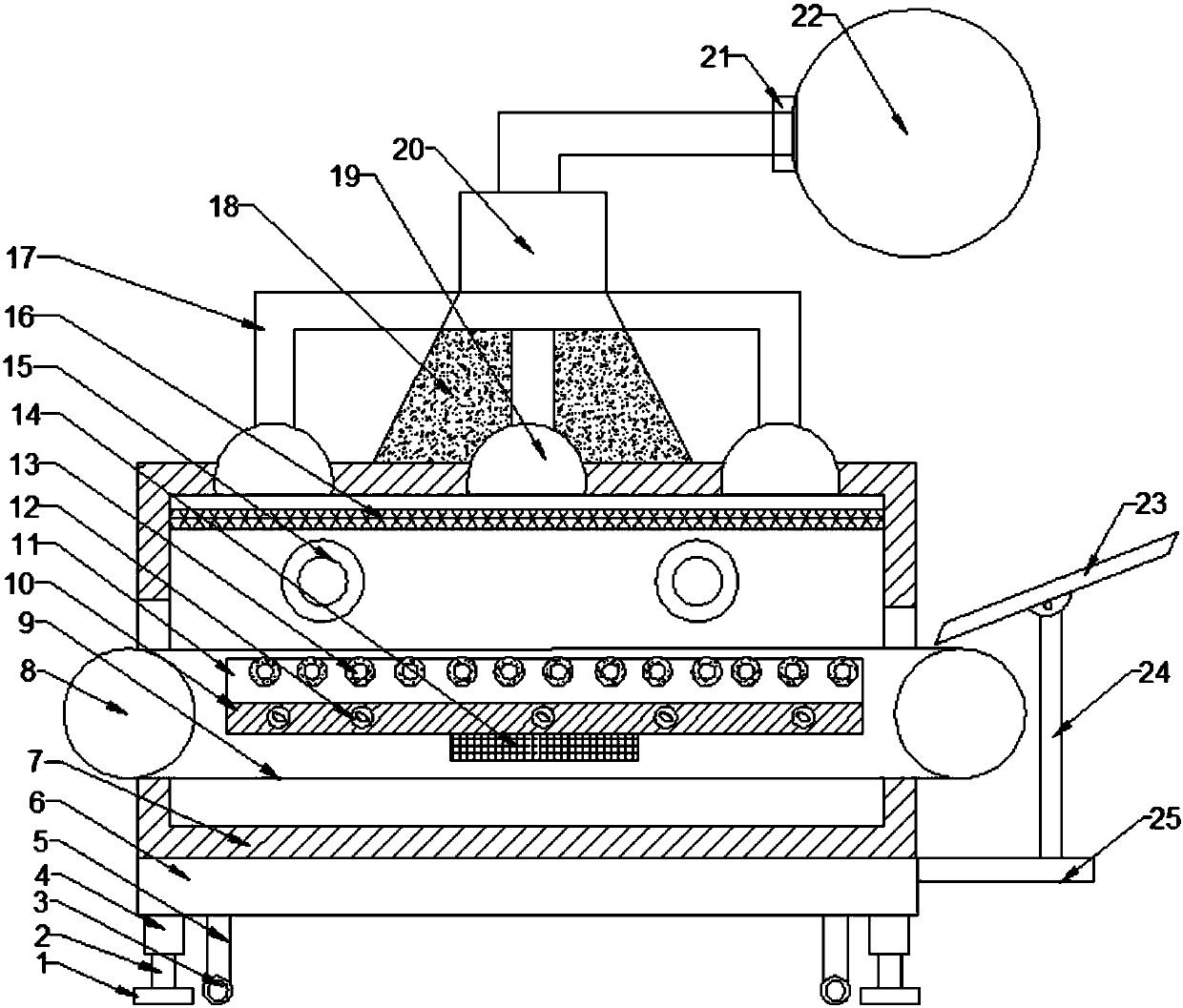

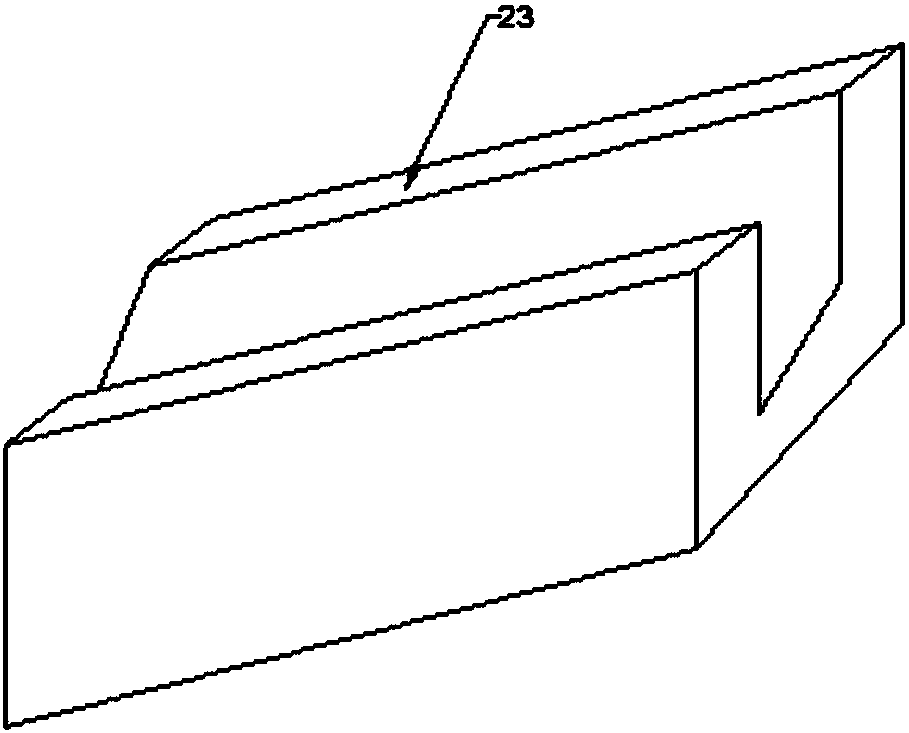

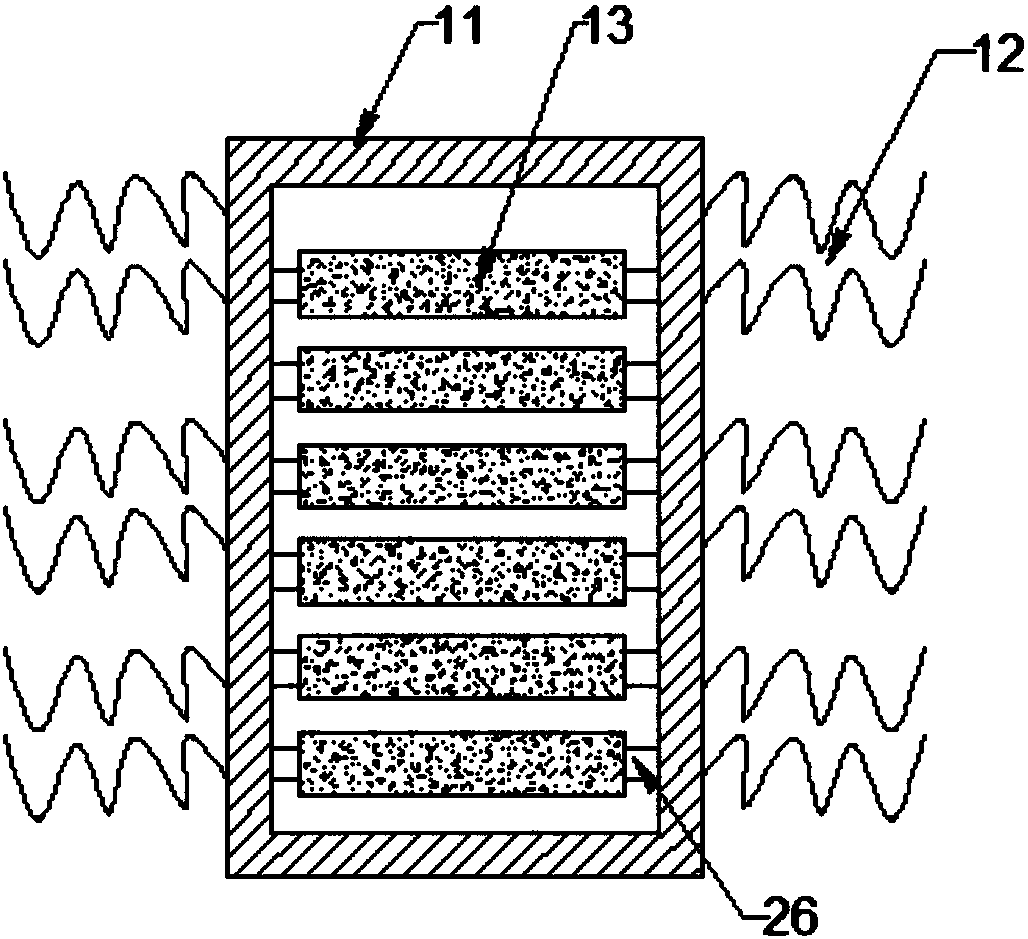

[0017] see Figure 1-3 , a dust removal device for powder metallurgy, including a support device and a dust removal device; the support device includes a fixed block 1, a drive rod 2, a roller 3, a driver 4, a support column 5 and a bottom plate 6; the support column 5 is arranged on the bottom plate 6 The lower sides of the bottom plate are fixedly connected, and the support column 5 is provided with a roller 3, which has the function of convenient movement; Below is provided with fixed block 1 by driving rod 2, and during work, driver 4 works, and driving rod 2 drives fixed block 1 to contact the ground, has the stable function of keeping device; Described dedusting device comprises dust removal box 7, transmission roller 8, Conveyor belt 9, supporting plate 10, roller bracket 11, connecting spring 12, roller 13, vibrator 14, air injection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com