Integral apparatus for cleaning work

An operation and cleaning technology, applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the environmental pollution of workover operations, reduce transportation time and other problems, achieve superior performance, high degree of automation, and automatic control process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

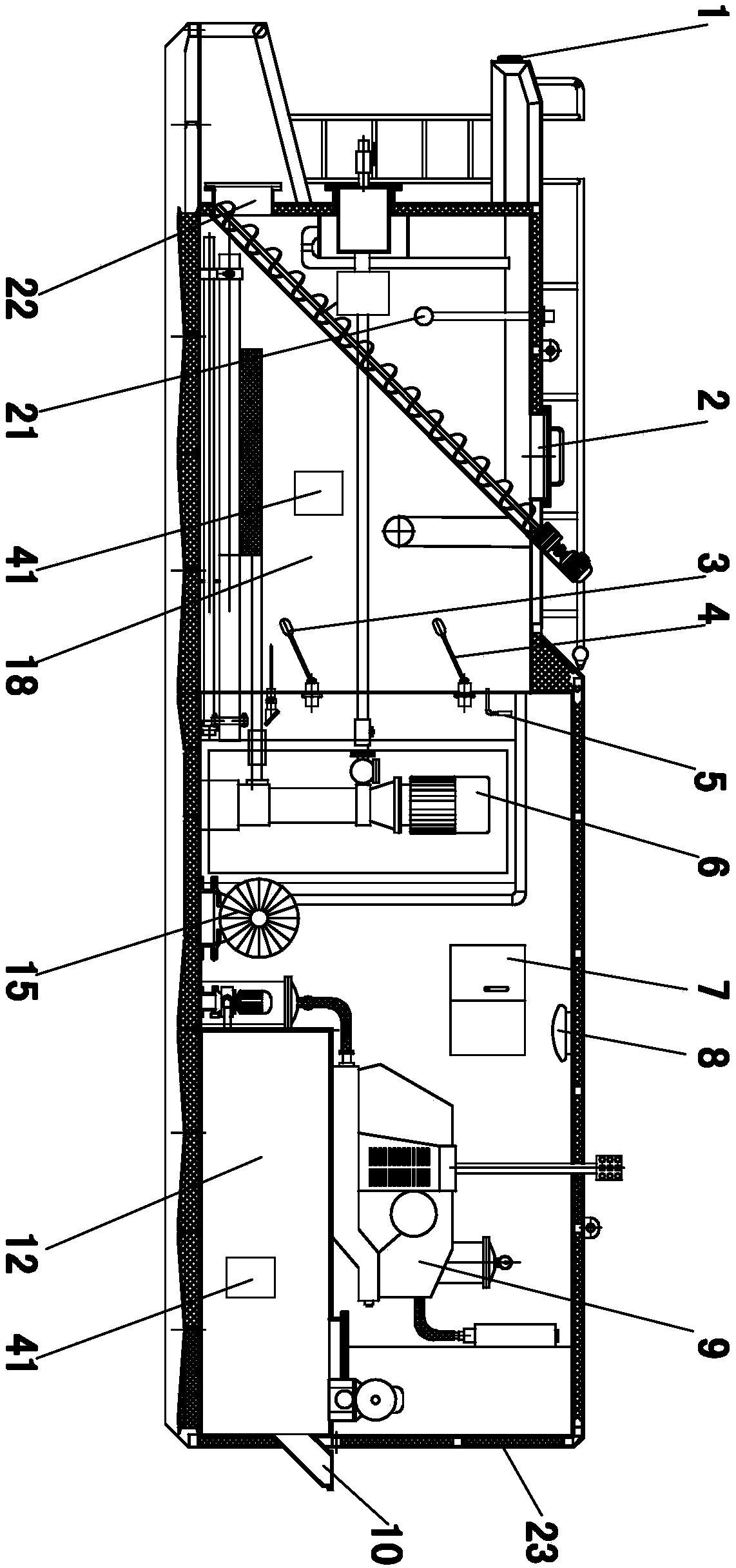

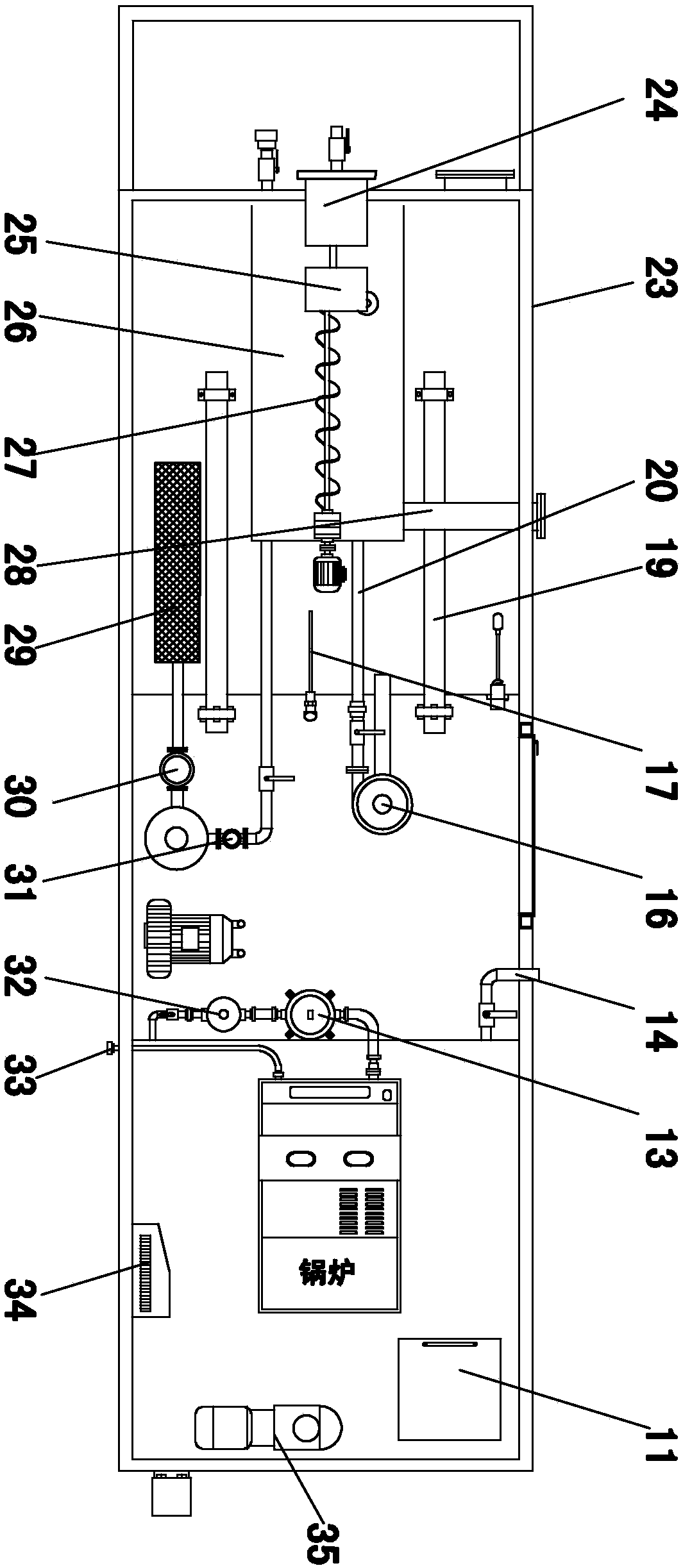

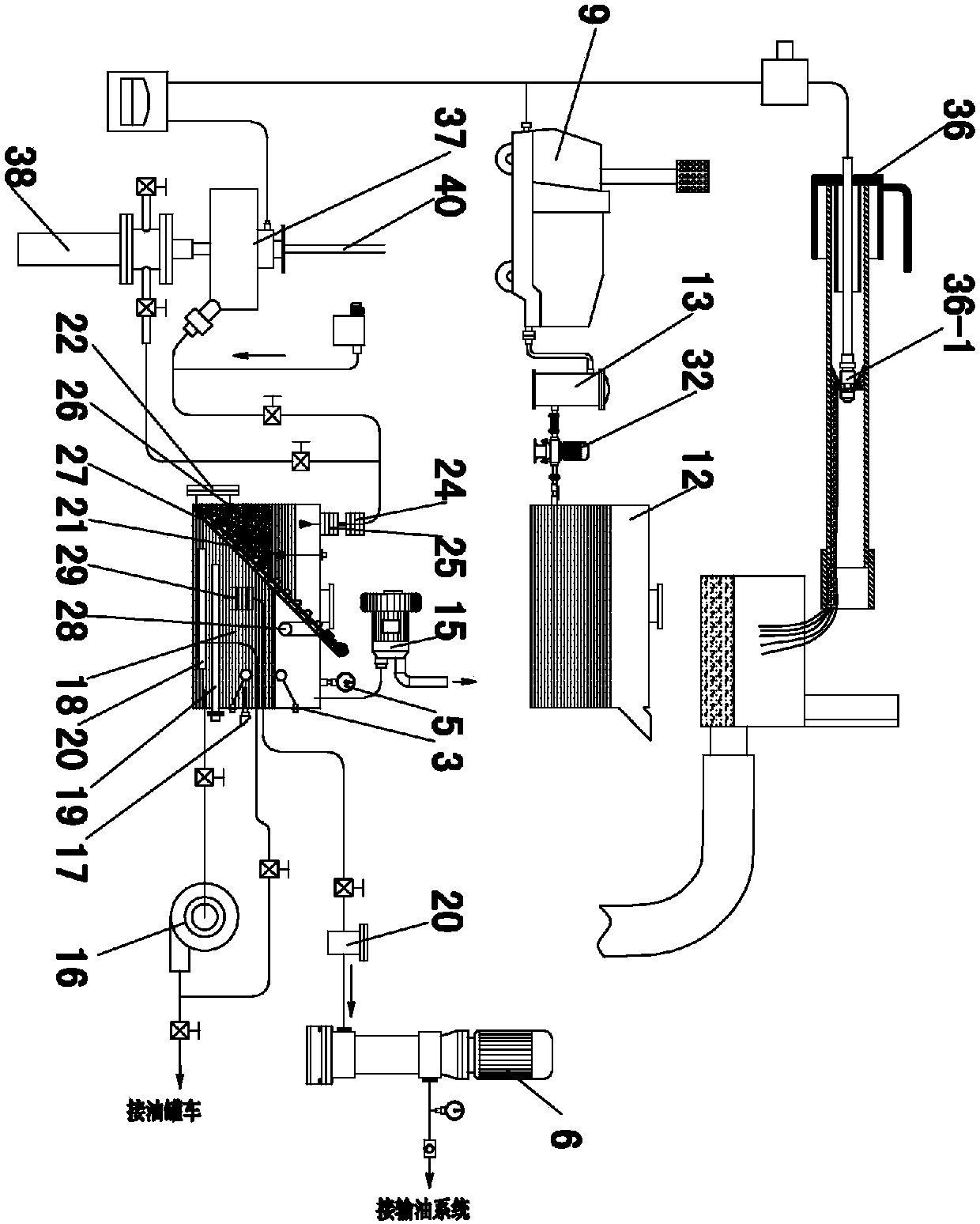

[0019] Such as Figure 1 ~ Figure 4 As shown, the cleaning operation integrated device is characterized in that it includes a main box body 23, a reinjection pump 6, a high-pressure hot water boiler 9, a clean water tank 12, a vacuum fan 15, a recovery tank 18, a solid-liquid separator 24, an oil-water separator device 25, grit chamber 26, spiral sand discharger 27, primary reinjection filter 29, secondary reinjection filter 30, boiler feed water pump 32, high pressure hot water joint 33, oil pipe inner wall cleaner 36 and degreasing cleaning Mechanism 37; the reinjection pump 6, clean water tank 12, high-pressure hot water boiler 9, boiler feed water pump 32, recovery tank 18, efflux pump 16 and vacuum blower 15 are all arranged in the main box body 23, and the high-pressure heat The water boiler 9, the boiler feed water pump 32 and the fresh water tank 12 are connected through pipelines sequentially, one end of the high-pressure hot water joint 33 is connected with the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com