Electronic hydraulic brake boosting system

A hydraulic braking and power assist system technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of brake fluid volume loss, high brake fluid pressure, system damage, etc., and achieve safe braking function , multiple functions, and the effect of solving the loss of brake fluid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

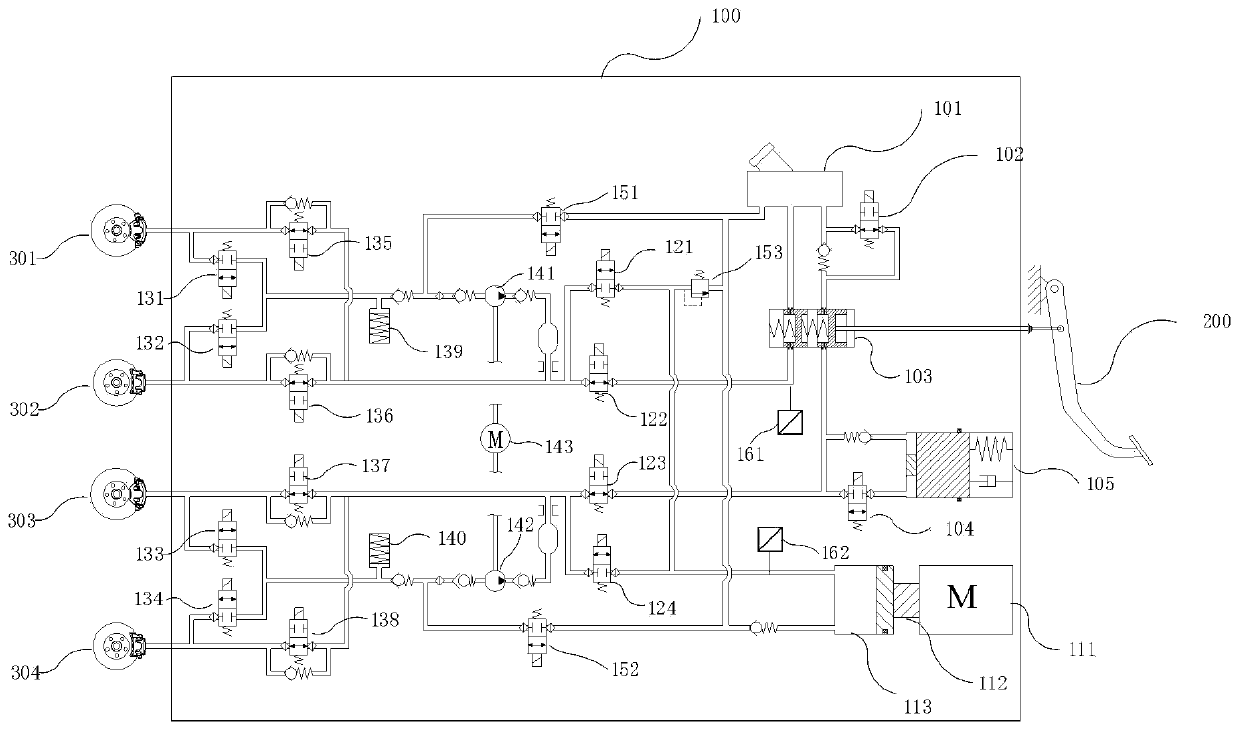

[0024] Such as figure 1 As shown, the embodiment of the present invention provides an electronic hydraulic brake booster system, including an electronic hydraulic brake booster system, a brake pedal, brake wheel cylinder 1, brake wheel cylinder 2, brake wheel cylinder 3 and brake wheel Cylinder four, the electronic hydraulic brake booster system includes a liquid storage tank and a brushless motor, and the liquid storage tank is fixedly connected with the source master cylinder, valve fourteen, valve fifteen and valve sixteen, and the liquid storage tank A master cylinder inlet valve is fixedly connected with one of the source master cylinders, one of the source master cylinders is fixedly connected with a pedal simulator, and the pedal simulator is fixedly connected with a pedal simulation inlet valve, and the pedal simulation inlet The valve is fixedly connected with valve three, one of the source master cylinders is fixedly connected with valve two, the brushless motor is f...

Embodiment 2

[0028] The normal boosting and active braking functions of an electronic hydraulic brake booster system: Valve 1, valve 2, valve 3 and valve 4 are powered on, and the pedal simulates the inlet valve to be powered on and opened. At this time, valve 2 and valve 3 are closed, and the driving The brake fluid stepped on by the driver can only enter the pedal simulator through the source master cylinder through the pedal simulation inlet valve. The pedal simulator generates pressure and provides pedal feeling. The pressure sensor senses the brake pressure pressed by the driver, and the brushless motor operates. , drive the power master cylinder to move through the deceleration mechanism, and the brake fluid enters the brake wheel cylinder 1, brake wheel cylinder 2, brake wheel cylinder through valve 1, valve 4, valve 9, valve 11, valve 12 and valve 13 Cylinder 3 and brake wheel cylinder 4, pressure sensor 2 senses the brake pressure generated by the active booster module and is used ...

Embodiment 3

[0030] An electric brake backup function of an electronic hydraulic brake booster system: when the brushless motor or the reduction mechanism or the power master cylinder is damaged and the brake cannot be generated, the pedal analog inlet valve is powered on and opened, and the valves 2 and 3 are powered off. Valve 14 and valve 15 are powered on and opened, and the brushed motor is powered on to drive plunger pump 1 and plunger pump 2, and the brake fluid is pumped by plunger pump 1 from the liquid storage tank through valve 14, valve 9, valve Eleven is pumped into brake wheel cylinder 1 and brake wheel cylinder 2, and the brake fluid is pumped into brake wheel cylinder 3 and brake by plunger pump 2 from the liquid storage tank through valve 15, valve 12 and valve 13 Wheel cylinder four realizes the electric brake backup function through the above mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com