Production process of cyclic regeneration antistatic fiber

An antistatic fiber and recycling technology, which is applied in fiber treatment, conductive/antistatic filament manufacturing, and complete sets of equipment for artificial thread production, can solve problems such as disappearance and weakening of antistatic effect, and achieve simple and easy process, Good market prospect, excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

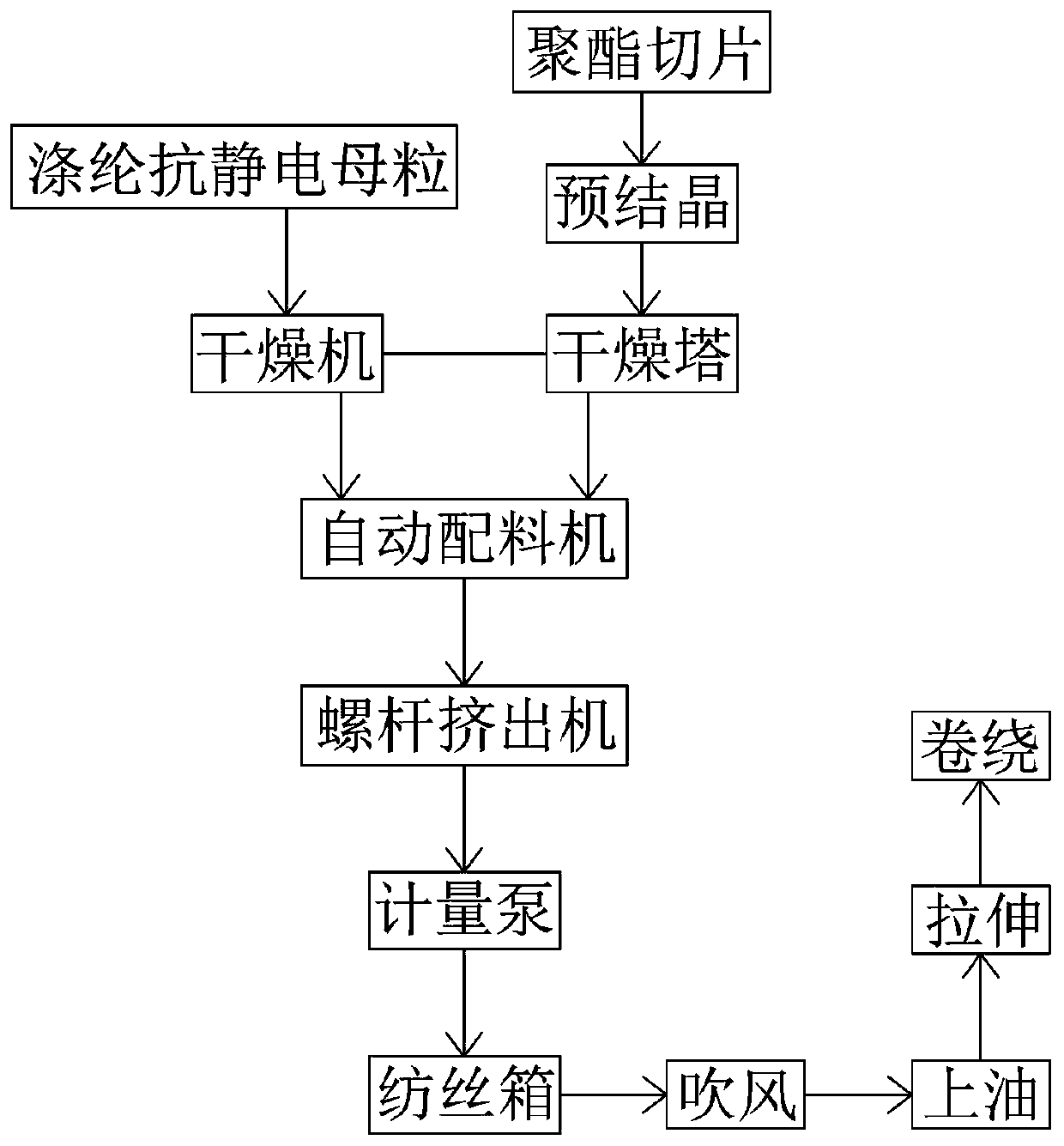

[0055] A production process of recycling antistatic fiber includes the following steps:

[0056] Raw material pretreatment: Put the polyester antistatic masterbatch into a dryer for drying. The polyester antistatic masterbatch adopts Klein NEA0425115 polyester antistatic masterbatch. The drying temperature of the dryer is 80℃, the drying time is 24H, and the drying wind pressure is 0.1MPa; pre-crystallize the polyester chips at a pre-crystallization temperature of 158℃, and send them to a drying tower for drying after pre-crystallization. The drying temperature is 160℃, the drying wind pressure is 0.08MPa, the drying tower material level is 35%, and the drying time Is 10H;

[0057] Raw material mixing: send the dried polyester antistatic masterbatch and polyester chips to the automatic batching machine, and the automatic batching machine will quantitatively output and mix the dried polyester antistatic masterbatch and polyester chips to obtain a mixture. The polyester in the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com