Grinding room with recycling function

A grinding room and functional technology, applied in the field of grinding room, can solve the problems of air pollution, high energy consumption of dust removal structure, grinding and emission pollution, etc., and achieve the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

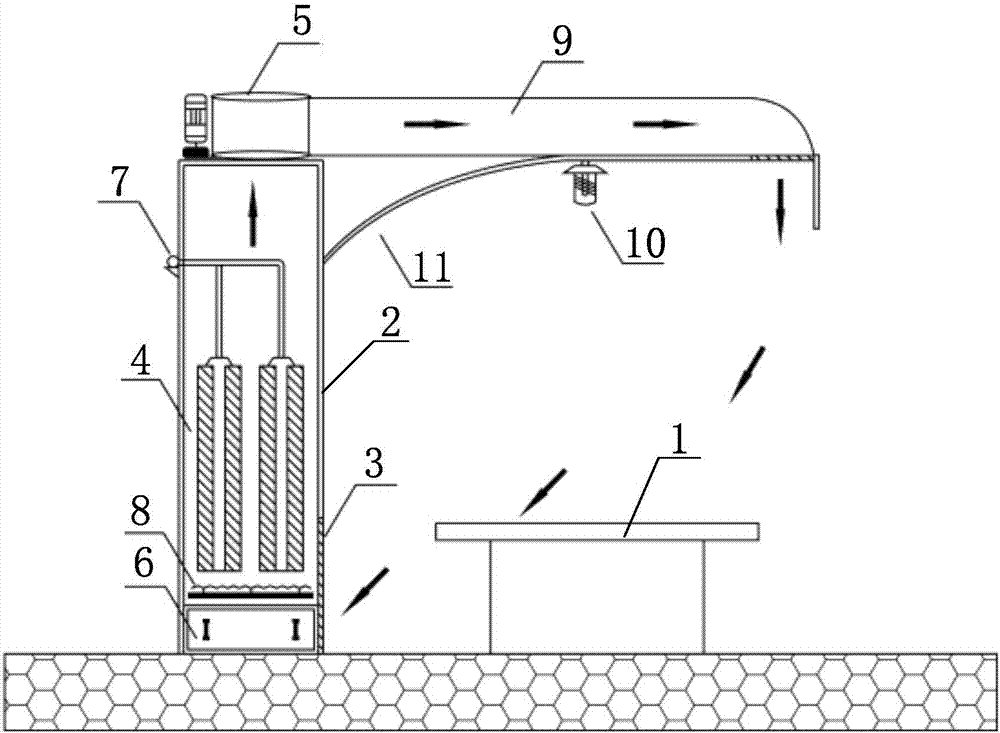

[0023] Such as figure 1 As shown, the grinding room with recovery function of the present invention includes a grinding table 1, and a dust suction recovery pipe 2 is arranged beside the grinding table 1, and a dust suction port is provided on the side of the dust suction recovery pipe 2 close to the grinding table 1 3. There is a bag filter device 4 inside the dust recovery pipe 2, and the pulse air pipe 7 is connected to the top of the bag filter device 4. The return air duct 9 is connected to each other, and the return air duct 9 is arranged horizontally and provided with an air outlet, and a dust storage bin 6 is provided below the bag filter device 4 .

[0024] The grinding room of the present invention can suck away the large-concentration dust generated by the surface grinding process and the deep processing of parts, collect it centrally, recycle the air, discharge the air in the room after the dust is removed, and recycle the clean air to the grinding room. Workers d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com