High-strength high-conductivity free-cutting copper alloy material and preparation method thereof

A technology of copper alloy and high conductivity is applied in the field of high-strength and high-conductivity free-cutting copper alloy materials and their preparation, which can solve the problems of complex technology, highly toxic oxides, low conductivity, etc., and achieve the effect of rich rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

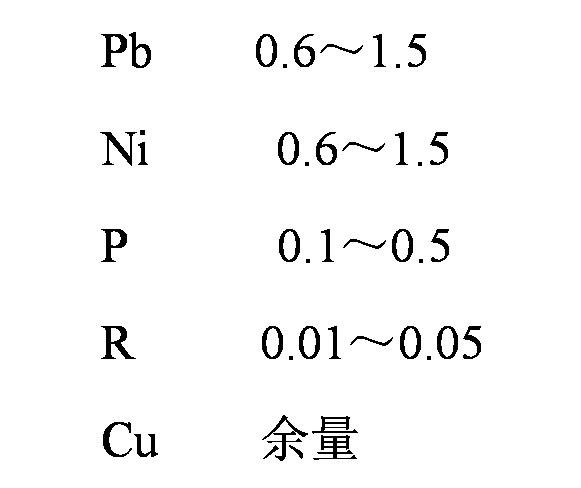

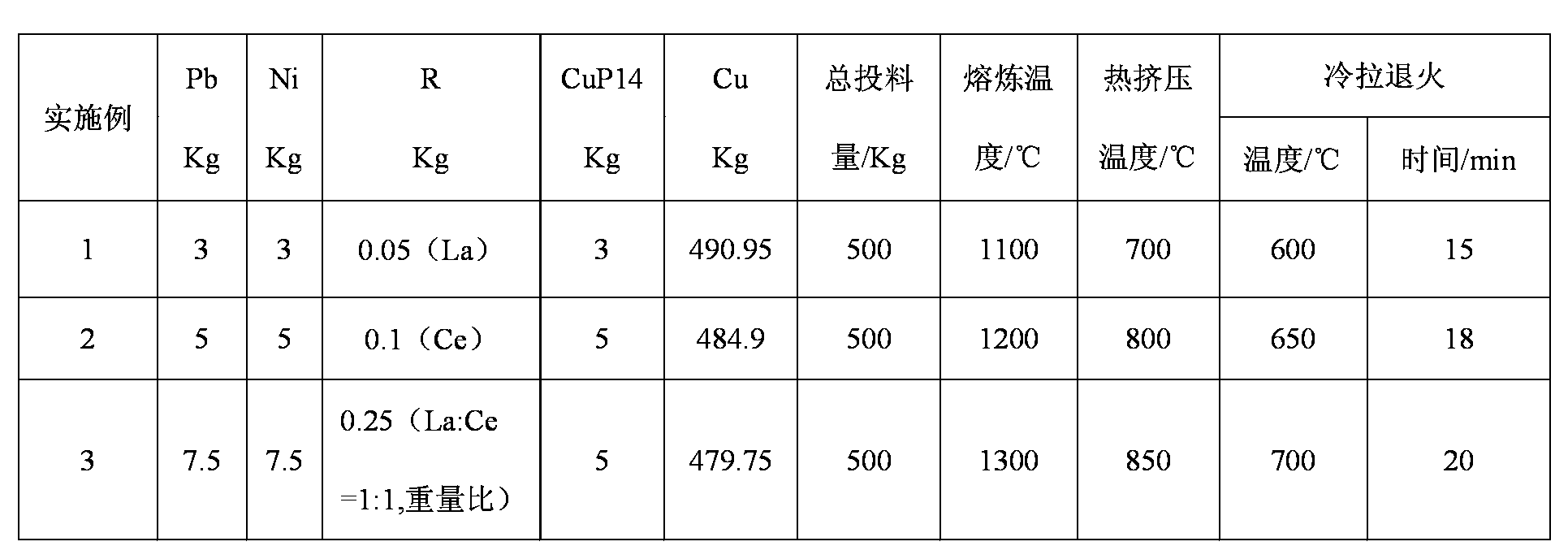

[0038] 1. Examples of preparation of high-strength and high-conductivity free-cutting copper alloy materials are shown in Table 1.

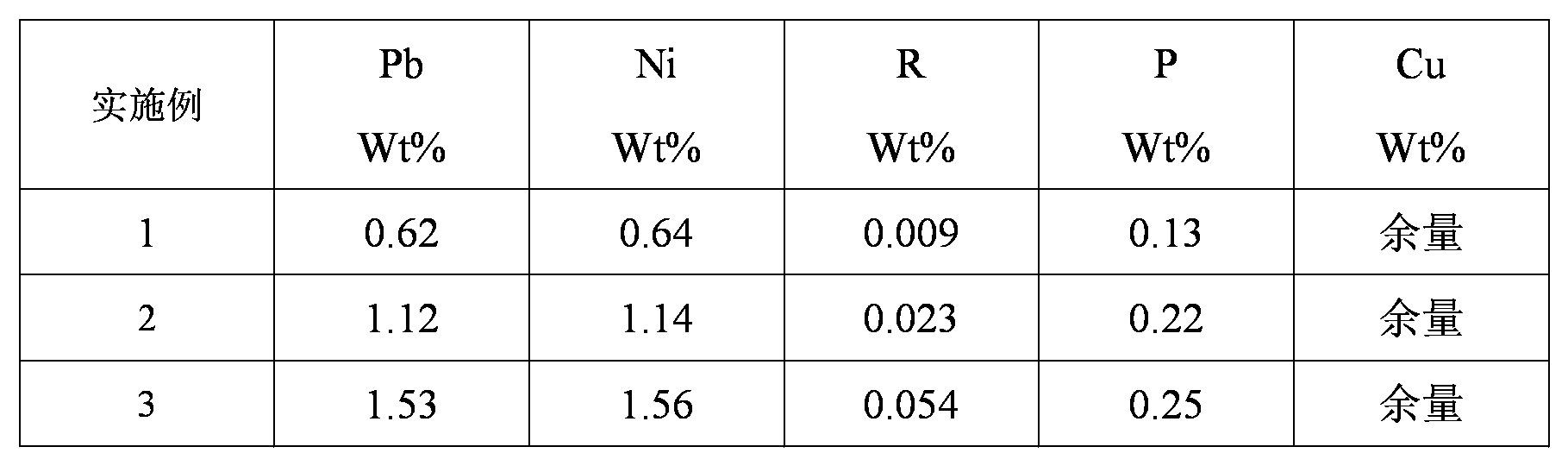

[0039] 2. The test results of the chemical composition of the smelted ingot are shown in Table 2.

[0040] 3. The test results of physical properties and mechanical processing properties of ingots processed into Φ11.5mm bars by hot extrusion, cold drawing and annealing are shown in Table 3.

[0041] Table 1 Preparation of high-strength and high-conductivity free-cutting copper alloy materials

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com