Underwater steel wire rope operation equipment with releasing and withdrawing functions

A wire rope and functional technology, applied in the field of underwater wire rope operation tools, lowering installation and unlocking recovery operation tools, can solve the problems of inconvenient use and singleness, and achieve the effects of convenient use and operation, enhanced reliability, and simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

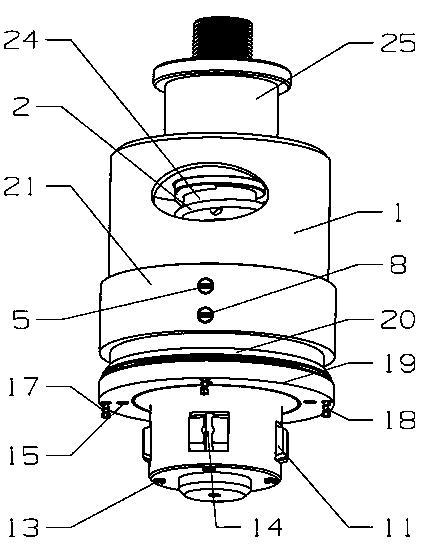

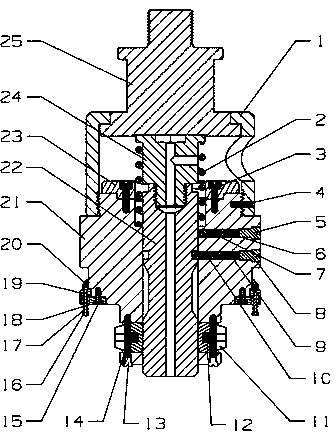

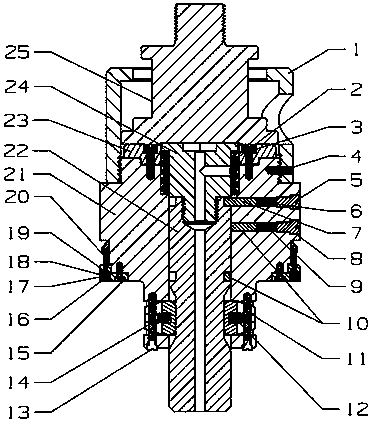

[0026] It includes a main body sleeve 21, the upper end of the main body sleeve is threadedly connected with the connecting sleeve 1, and is locked by the stop screw 4, the lower end of the connecting sleeve is provided with internal threads connected with the main body sleeve, and an observation hole is opened on one side. The top is provided with a stop flange, and the connecting sleeve is socketed with the top joint 25; the upper end of the top joint is provided with threads, the middle is provided with a fishing neck, and the lower end is a bottom round table with the largest outer diameter. bore configuration. An upper backing ring 23 is arranged on the upper end surface of the main body sleeve. The upper backing ring is connected with the main body sleeve through bolts 3. The upper backing ring is used to limit the downward stroke of the top joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com